Vibrating and backflushing integrated bag type dust remover

A bag-type dust collector, an integrated technology, applied in chemical instruments and methods, separation of dispersed particles, filtration of dispersed particles, etc., can solve the problems of difficult cleaning, increased filter bag resistance, mechanical vibration frequency and amplitude not too fast To achieve the effect of reducing dust agglomeration, reducing equipment operation resistance and pressure fluctuation, and reducing equipment operation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

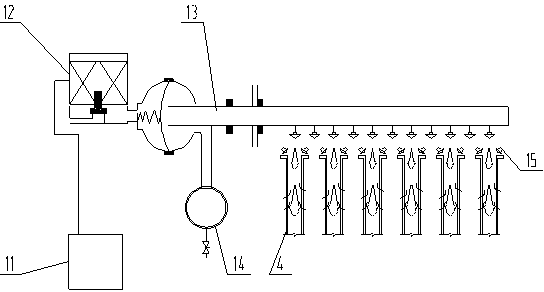

[0016] like figure 1 As shown, the low-resistance mechanical rapping and pulse blowback integrated bag filter of the present invention includes a housing 3 , a filter bag 4 , a mechanical rapping device 9 , a gas distribution structure, and a pulse blowback device 2 . The lower part of the housing 3 is provided with a dusty gas inlet 5, and the upper part is provided with a purified gas outlet 1. The housing 3 is provided with a flower plate 10 (gas distribution structure), a filter bag 4 and a pulse blowback device 2. The pulse blowback device 2 The blowback pipe is correspondingly arranged in the area of the outlet of the purified gas.

[0017] The pulse blowback device 2 includes a pulse controller 11, a solenoid valve 12, a blowback pipe 13, and an air bag 14. The pulse controller 11 is connected to the solenoid valve 12, the blowback pipe 13 is connected to the air bag 14, and the solenoid valve 12 is located on the blowback pipe 13. On the connecting pipeline with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com