Method for preparing electrospun artificial blood vessel with micro-nano biomimic intima structure

A technology of artificial blood vessels and electrospinning, applied in the direction of human tubular structure devices, blood vessels, etc., to achieve the effect of improving blood compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

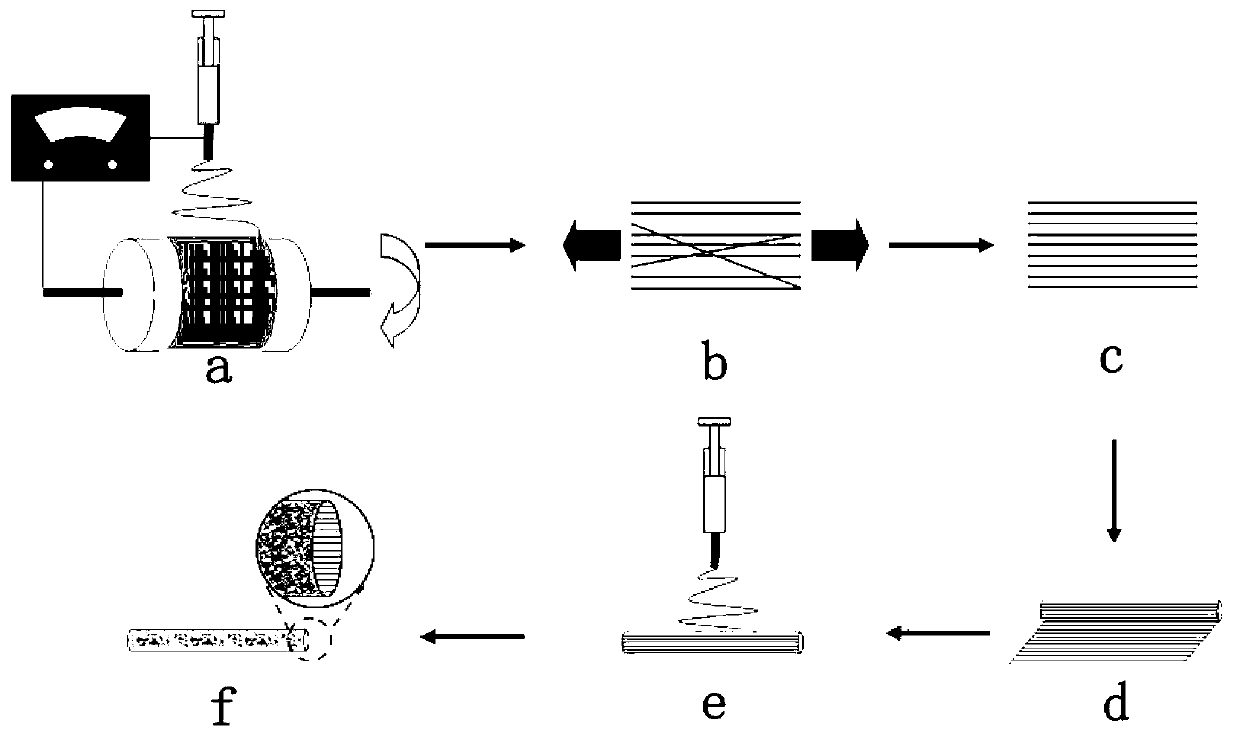

[0039] Preparation of Polyurethane Artificial Blood Vessel with Micro-Nano Biomimetic Intima Structure

[0040] 1. Preparation of polyurethane solution

[0041] Dissolve polyurethane particles into a mixed solution of tetrahydrofuran and N,N-dimethylformamide with a volume ratio of 7:3, and stir for about 3 hours to form a clear, stable and uniform solution.

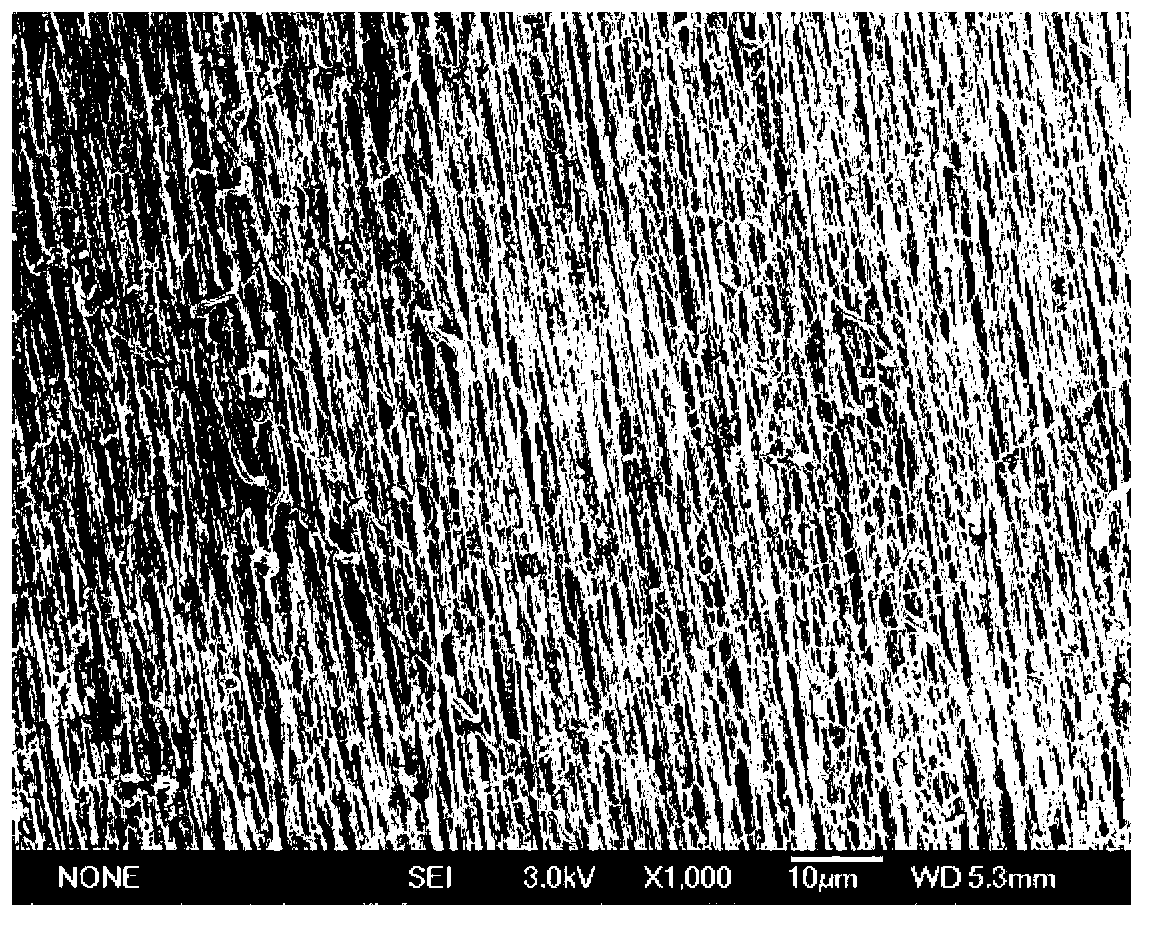

[0042] 2. Preparation of oriented electrospun fiber membrane

[0043] Move the solution into a 5ml syringe, then fix the syringe on the vertical support, connect the needle to the high voltage power supply, the distance between the needle and the upper end of the drum is 25cm, start the drum, set the speed to 3000rpm, and then apply 10-30KV After 30 minutes of high pressure, a film with an oriented fiber structure can be obtained.

[0044] 3. Stretching of oriented electrospun fiber membranes

[0045] In order to obtain a better degree of orientation, the oriented fiber film was stretched 120% along the long axis of th...

Embodiment 2

[0055] Preparation of polycaprolactone artificial blood vessel with micro-nano biomimetic intima structure

[0056] 1. Preparation of polycaprolactone solution

[0057] Dissolve polycaprolactone particles into a mixed solution of dichloromethane and N,N-dimethylformamide with a volume ratio of 5:5, and stir for about 3 hours to form a clear, stable and uniform solution.

[0058] 2. Preparation of oriented electrospun fiber membrane

[0059] Move the solution into a 5ml syringe, then fix the syringe on the vertical support, connect the needle to the high voltage power supply, the distance between the needle and the upper end of the drum is 27cm, start the drum, set the speed to 4000rpm, and then apply 10-30KV After 30 minutes of high pressure, a film with an oriented fiber structure can be obtained.

[0060] 3. Stretching of oriented electrospun fiber membranes

[0061] In order to obtain a better degree of orientation, the oriented fiber film was stretched 150% along the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com