Combined machine for pressing rod

A technology of pressing rods and instruments, which is applied in the field of combined pressing rods and instruments, can solve the problems of prolonged operation time, incomplete operation, excessive lifting process, etc., and achieve the effects of reducing operation risk, saving operation time, and widening the field of vision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

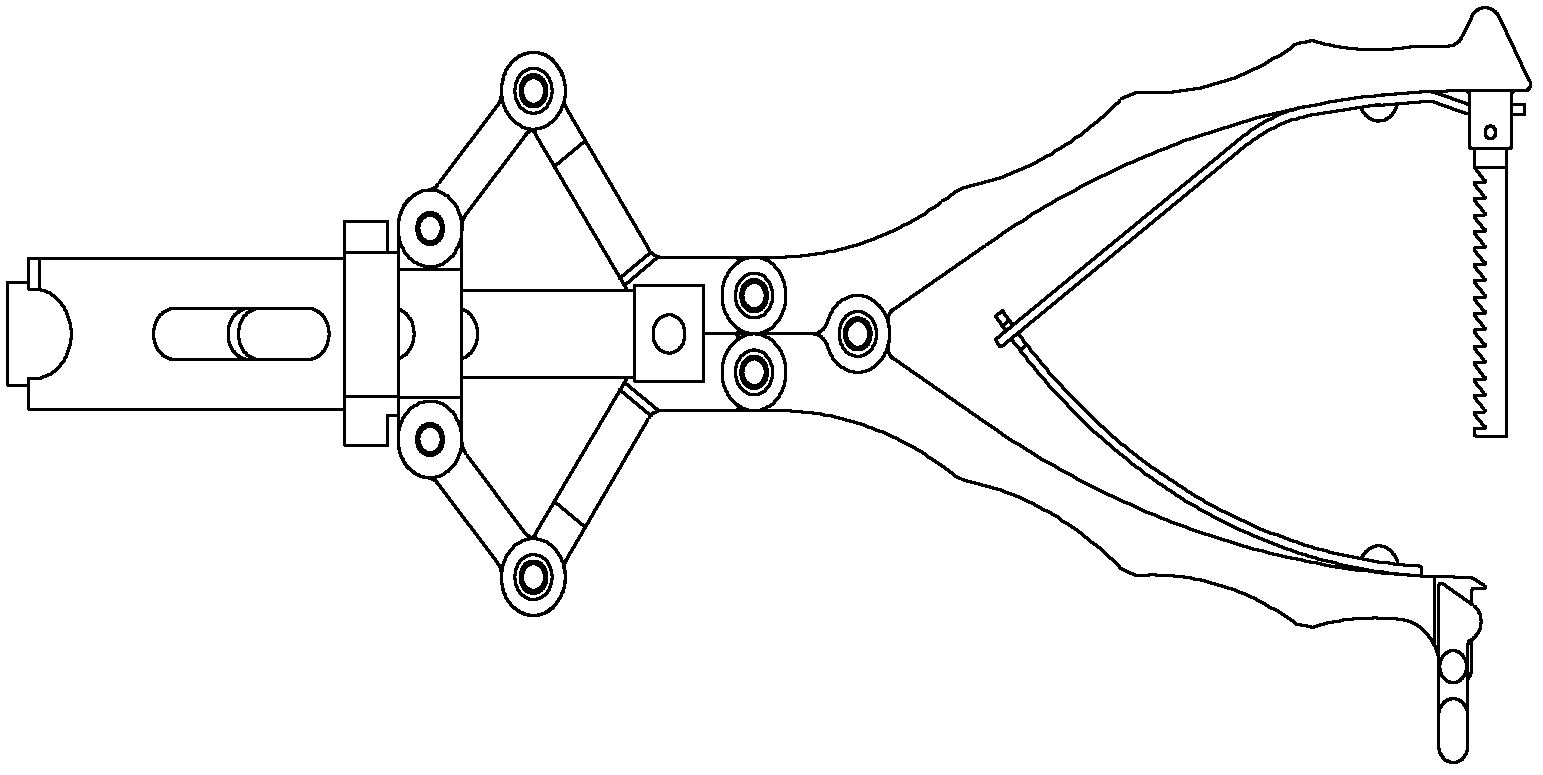

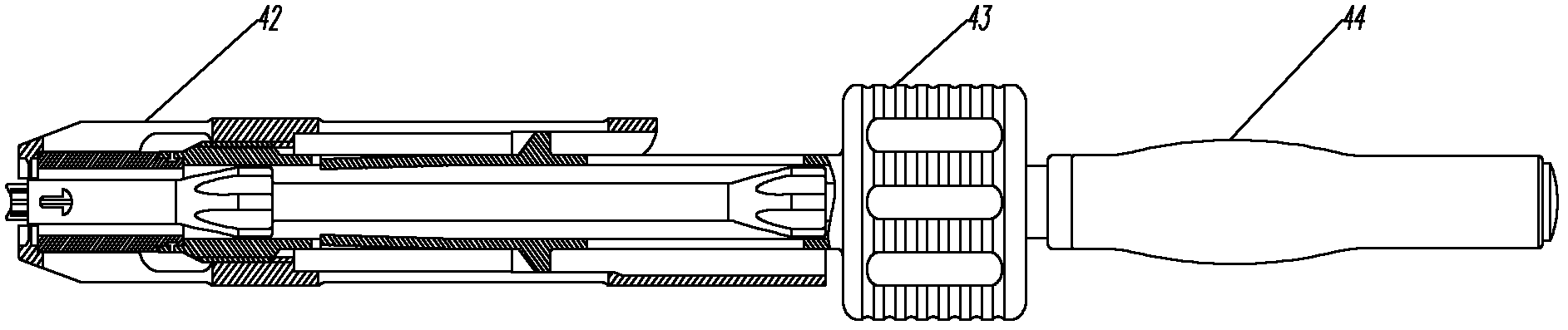

[0035] see figure 2 As shown, the bar pressing combination device of the present invention includes a bar pressing pliers 42 , a reset core 43 and a screw holder 44 that are sheathed and connected sequentially from outside to inside.

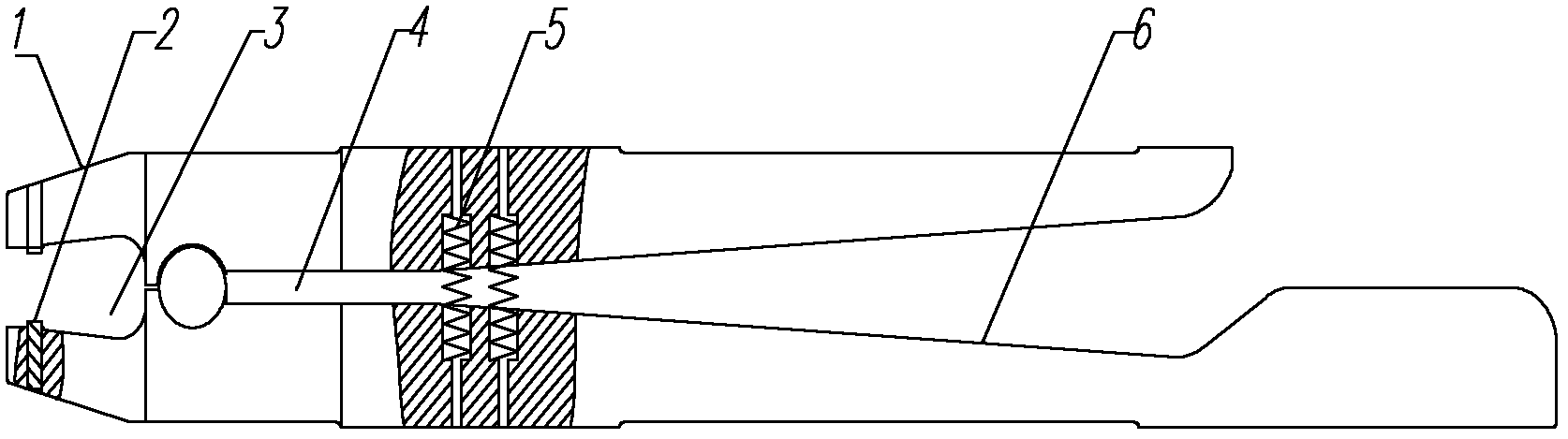

[0036] Among them, see Figure 3-5 As shown, the pressing rod pliers 42 are mainly composed of an upper pliers body 1 and a lower pliers body 6. The upper and lower pliers bodies are connected together by a pin shaft 7 arranged on the left and right sides to form a whole. The upper pliers body 1 and the lower pliers body The lower caliper body 6 can perform an appropriate amount of rotational movement around the pin shaft 7 . The spring 5 connecting the upper and lower tong bodies is provided behind the pin shaft 7 and inside the upper and lower tong bodies, so that the upper tong body 1 and the lower tong body 6 are automatically reset after rotating around the pin shaft 7. Preferably, four holes can be respectively opened on the inside of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com