Equipment and method for sectional fine sorting of tobacco sheets

A cigarette and equipment technology, which is applied in the field of sectional selection equipment for cigarettes, can solve the problems of low operation efficiency, multi-manpower, and inability to achieve screening and rejection of small-shaped, small-stem diameter, and stalked tobacco slices.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

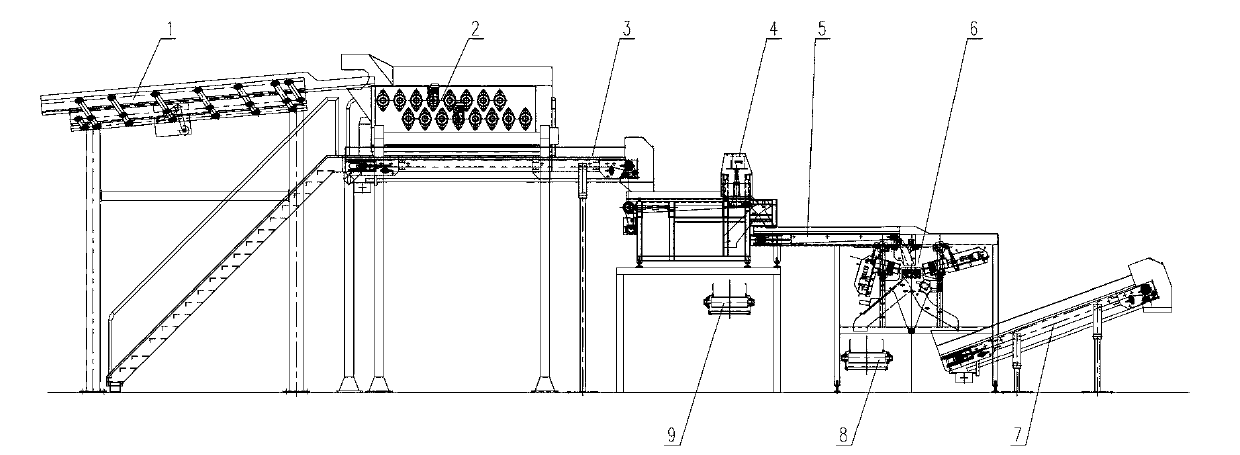

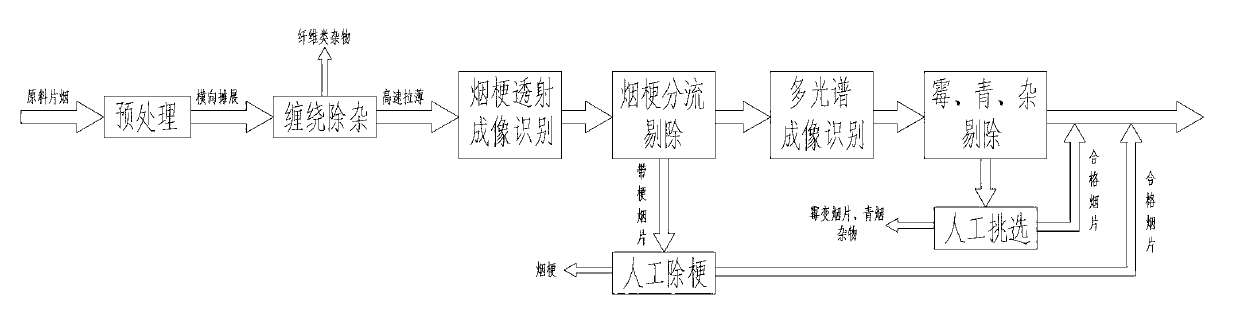

[0082] Such as figure 2 A method for segmenting and selecting sliced cigarettes comprises the following steps:

[0083] Step 1: pretreatment; for horizontal spreading material (ie tobacco leaves),

[0084] Step 2: winding and removing impurities;

[0085] Using the hemp removing device to remove fibrous impurities such as hemp and hemp rope mixed in the tobacco leaves;

[0086] Step 3: Tobacco stem transmission imaging recognition + tobacco stem shunt removal;

[0087] Using the tobacco stem detection and removal device to remove the stemmed impurities in the tobacco leaves;

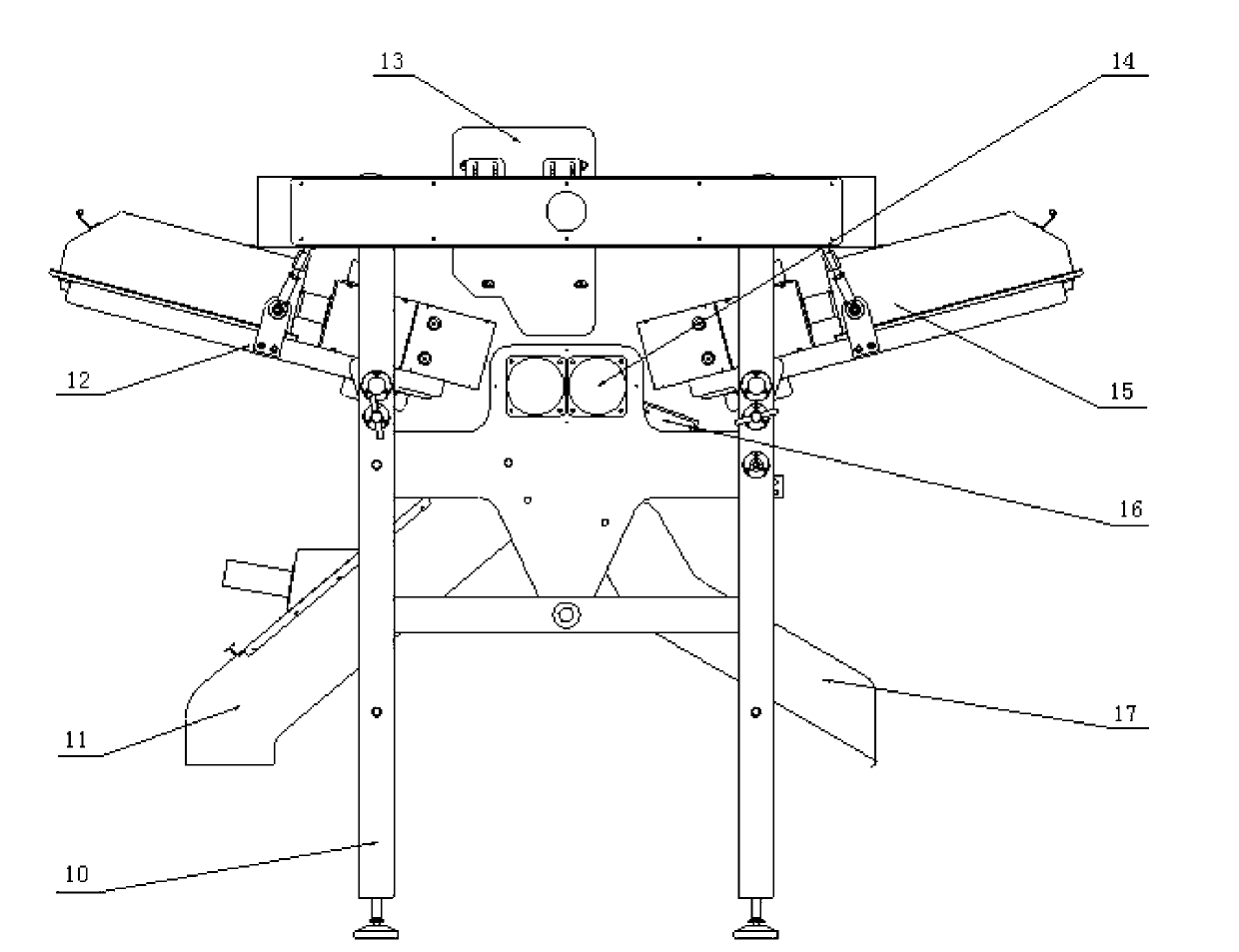

[0088] Step 4: Multispectral imaging recognition + Penicillium removal;

[0089] Using the free-falling green smoke and moldy smoke detection and removal device based on image processing to detect and remove the green smoke and mildew smoke in the tobacco leaves;

[0090] Step 5: manual destemming and manual selection;

[0091] Manual destemming adopts the manual leaf selection unit to remove th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com