Corn ear test method

A corn ear and corn cob technology, which is applied in the directions of seed and rhizome treatment, measuring device, instrument, etc., can solve the problems of error, increase labor cost, high labor cost, etc. The effect of reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

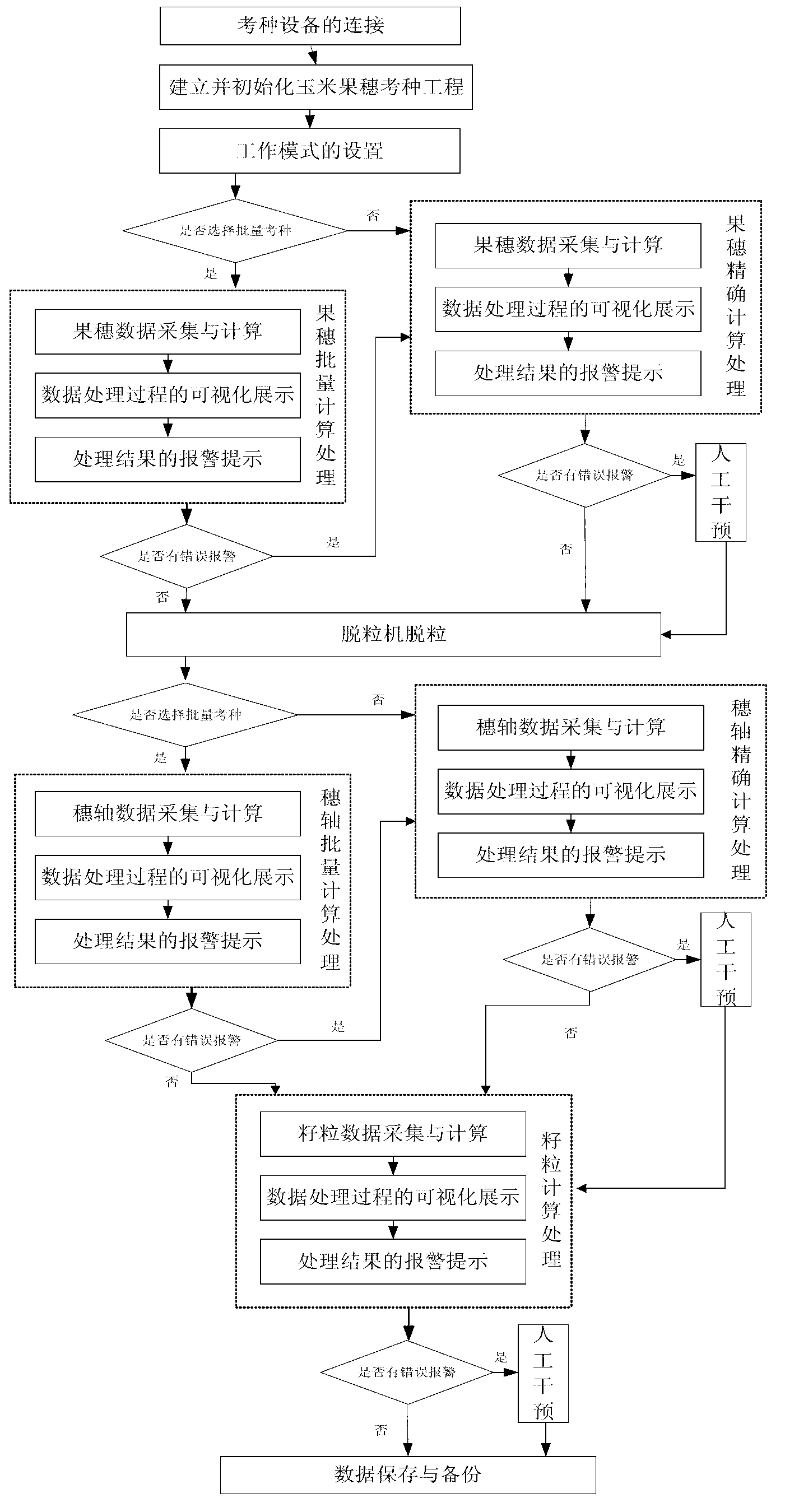

[0042] Steps see figure 1 . S1 test equipment connection: batch corn ear test system includes industrial camera MVC1000 (micro-vision image, model MVC1000, LED light source), weight sensor (Tianjin Lijing Microelectronics Equipment Co., Ltd.), sensor data acquisition card (Altai technology, model USB5953); the batch corn ear seed testing system has 5 ear trays, and there is a weight sensor under each tray.

[0043]The accurate corn ear seed test system includes weight sensor, stepper motor (Shanghai Sihong Electric Co., Ltd., model: 35BYGH), industrial camera MVC1000, sensor data acquisition card (Altai Technology, model USB5953); the corn ear or cob to be tested Fix it vertically with a nail, and the stepper motor drives the fixed ear or cob to rotate; the weight sensor passes through the data acquisition card USB5953, and the camera stores the data into the computer through the Gigabit network card.

[0044] The threshing system includes a thresher.

[0045] The corn seed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com