Manufacture Technology of Boss Printed Board by Addition Method

A technology of manufacturing process and additive method, which is applied in the direction of printed circuit manufacturing, printed circuit, conductive pattern formation, etc., can solve the problems of copper waste, difficult control, complicated process, etc., and achieve the effect of low price, easy control and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

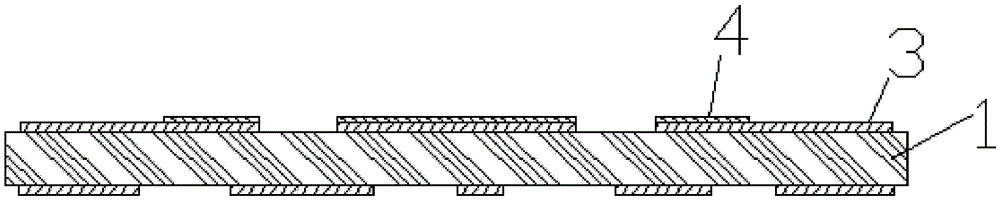

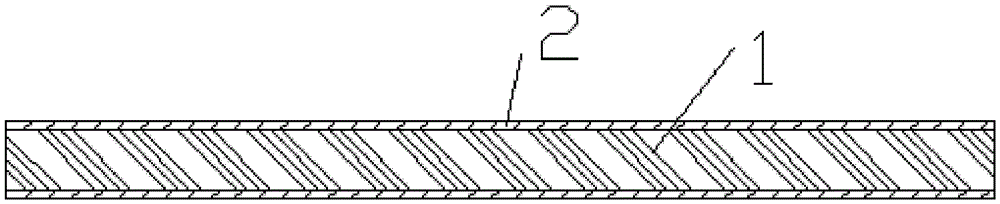

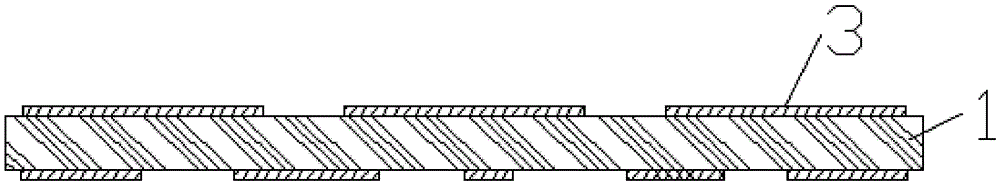

[0026] A manufacturing process of additive boss printed boards. Firstly, the base material is selected as the insulating substrate 1; That is, a layer of copper layer 2 is respectively plated on the upper and lower sides of the insulating substrate (such as figure 2 shown); then carry out pattern transfer and etching / removing film to the copper clad laminate to obtain a PCB board containing the first step 3 (such as image 3 As shown), the metal boss 4 is added on the first step of the PCB board containing the first step using an additive method.

[0027] Preferably, the method of adding the metal boss by the above-mentioned additive method is one of spot tin, spot welding and electroplating.

[0028] Preferably, the above-mentioned point-tin type addition method to add a metal boss includes the following steps: first, on the first step of the PCB board containing the first step, there is no need to add a choke ring 5 at the place where the metal boss is added (such as Fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com