Rolling stamping flattener for aluminum-plating paper

A technology of leveling machine and aluminized paper, applied in paper machine, paper making, physical treatment of paper, etc., can solve the problems of unsafe steam generator, high energy consumption of steam and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

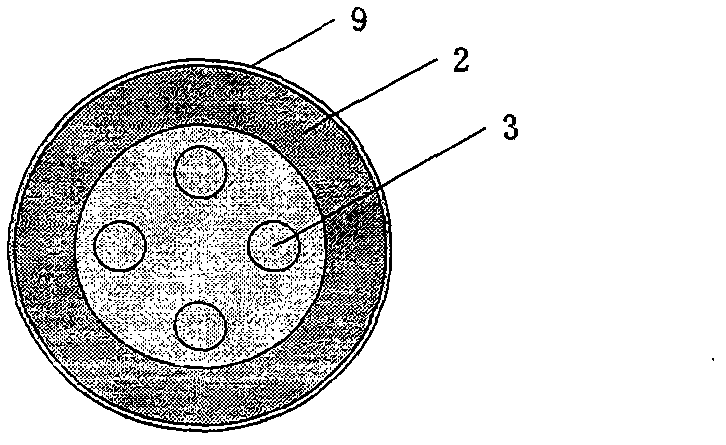

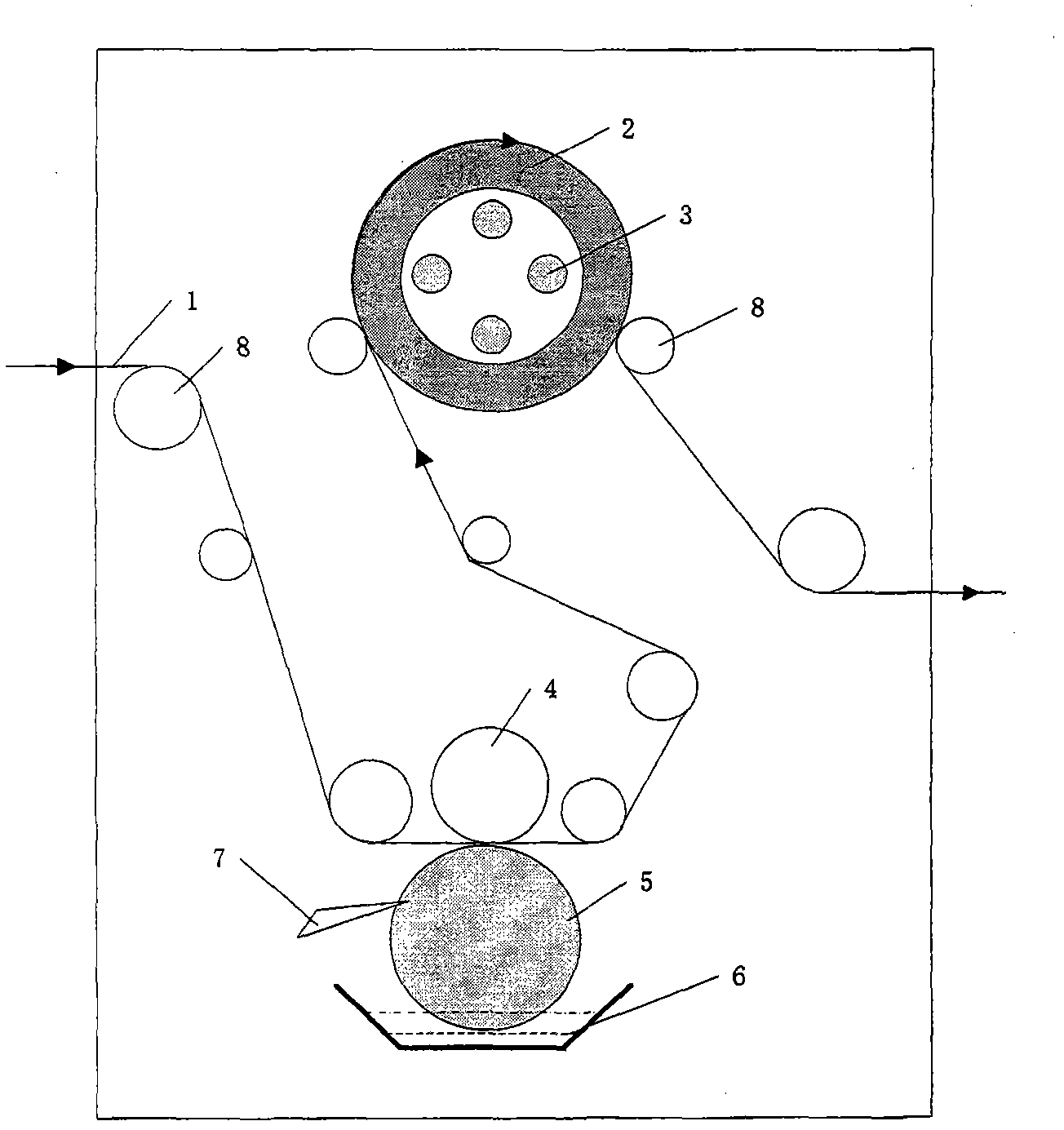

[0009] figure 1 The heated chrome-plated layer 9 of the middle chrome-plated ironing roller 2 vaporizes the tap water at normal temperature on the back side of the aluminum-plated paper 1 to accelerate the movement of water molecules;

[0010] Such as figure 2 As shown, the cross-sectional structural diagram of a preferred embodiment of the present invention, the described aluminum-coated paper moisture regain scalding leveler includes a tungsten steel scraper 7 that is close to the metal anilox roller 5 and the built-in heating tube 3 at a certain angle. Chrome-plated ironing roller 2.

[0011] When regaining moisture in this example, add a small amount of tap water in the water tank 6 of the scalding leveler, and immerse the metal anilox roller 5 2-3cm in water depth, and simultaneously heat the heating tube 3 to 120-140°C. The aluminized paper 1 passes through a plurality of paper guide rollers 8, contacts the metal anilox roller 5 with the paper back, passes through the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com