Method for preparing fumaric acid through cis-trans isomerization of maleic acid

A technology of cis-trans isomerization and maleic acid, applied in the field of preparation of fumaric acid, can solve the problems of excessive waste liquid, large amount of catalyst, corrosion of catalyst to equipment, etc., and achieves high catalytic efficiency, low production cost, and product high yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

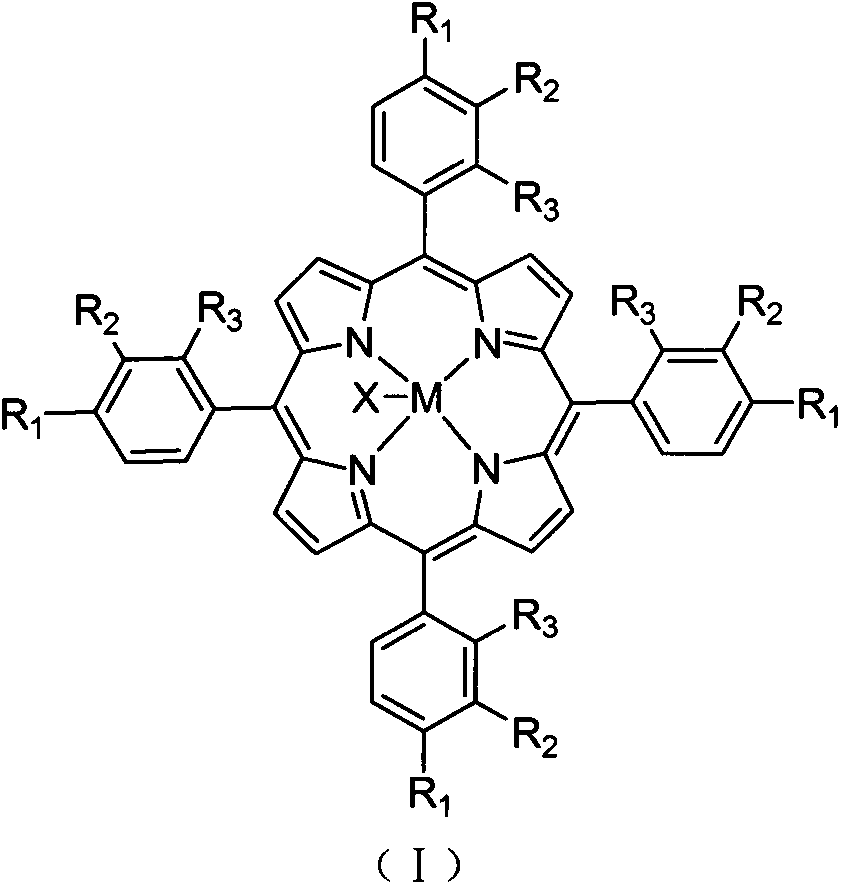

[0015] 2 mg of metalloporphyrins of formula (I), R 1 is cyclodextrin, R 2 for CH 3 , R 3 is H, M is Mn, X=C1, add 2g of maleic acid and 40ml of DMF, continuously feed air, the reaction pressure is 0.1Mpa, the flow rate is 0.05L / min, the reactant is stirred at 100°C for 5 hours, the product The yield of fumaric acid was 85%.

Embodiment 2

[0017] 3 mg of a metalloporphyrin of formula (I), R 1 , R 2 for Cl, R 3 is H, M is Mn, X is Br, add 1.6g maleic acid and 35ml DMF, continuously feed oxygen, the reaction pressure is 1.2Mpa, and the flow rate is 0.03L / min. The reactant was stirred at 120° C. for 8 hours, and the yield of the reaction product fumaric acid was 94%.

Embodiment 3

[0019] Chitin is immobilized with 3 mg metalloporphyrins of structural formula (I), R 1 for NO 2 , R 2 , R 3 Cl is Cl, M is Co, X is Br, add 1.5g maleic acid and 40ml xylene, continuously feed oxygen-deficient air containing 15% (v / v) oxygen, the reaction pressure is 0.2Mpa, and the flow rate is 0.03L / min. The reactant was stirred at 100° C. for 6 hours, and the yield of the reaction product fumaric acid was 88%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com