Food additive silica gel and production process of food additive silica gel

A technology of food additives and production technology, which is applied in the direction of silicon compounds, inorganic chemistry, non-metallic elements, etc., can solve the problems of long drinking cycle, etc., and achieve the effect of improving adsorption capacity, ensuring filtration speed, and unaffected production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

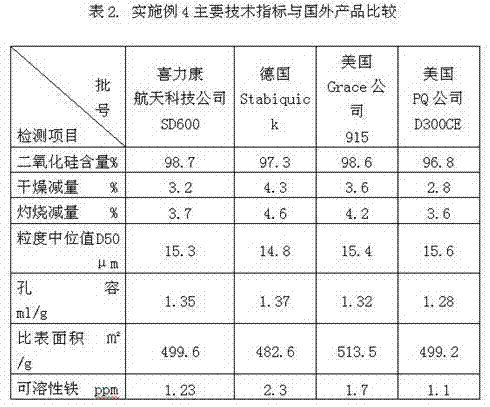

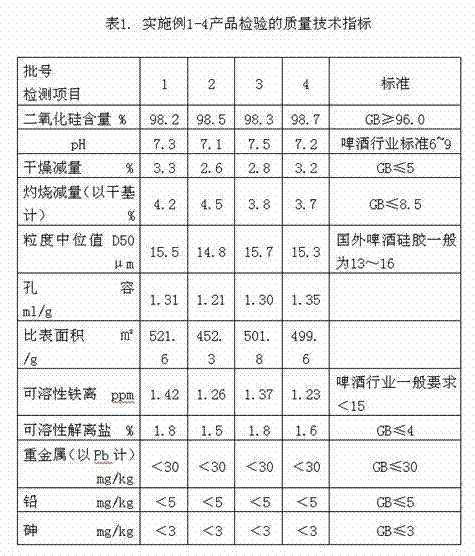

Examples

Embodiment 1

[0030] A kind of food additive silica gel of the present embodiment is the silica gel with three-dimensional space network structure, is X-ray amorphous substance, and its soluble iron ion content is 1.42ppm, and particle size median value D50 is 15.5μm, ratio The surface area is 521.6㎡ / g, the pore volume is 1.31ml / g, and the average pore diameter is 10.0nm.

[0031] A kind of production technology of food additive silica gel of the present invention specifically comprises the following steps:

[0032] (1). Raw material preparation: choose food-grade sodium carbonate and quartz sand, after high-temperature firing to obtain sodium silicate with a modulus of 3.35-3.40, add tap water in a closed melting tank to dissolve and filter, and prepare SiO 2 Sodium silicate solution with a concentration of 14-16%; choose food-grade sulfuric acid, and adjust it to a dilute sulfuric acid solution of 18-22% with tap water.

[0033] (2). Reaction gel making: the above-mentioned sodium silica...

Embodiment 2

[0039] A kind of food additive silica gel of the present embodiment is the silica gel with three-dimensional space network structure, is X-ray amorphous material, and its soluble iron ion content is 1.26ppm, and particle size median value D50 is 14.8 μm, ratio The surface area is 452.3㎡ / g, the pore volume is 1.21ml / g, and the average pore diameter is 10.7nm.

[0040] A kind of production technology of food additive silica gel of the present invention specifically comprises the following steps:

[0041] (1). Raw material preparation: choose food-grade sodium carbonate and quartz sand, after high-temperature firing to obtain sodium silicate with a modulus of 3.35-3.40, add tap water in a closed melting tank to dissolve and filter, and prepare SiO 2 Sodium silicate solution with a concentration of 14-16%; choose food-grade sulfuric acid, and adjust it to a dilute sulfuric acid solution of 18-22% with treated deionized water.

[0042] (2). Reaction gel making: the above-mentioned...

Embodiment 3

[0048] A kind of food additive silica gel of the present embodiment is the silica gel with three-dimensional spatial network structure, is X-ray amorphous material, and its soluble iron ion content is 1.37ppm, and particle size median value D50 is 15.7μm, ratio The surface area is 501.8㎡ / g, the pore volume is 1.30 ml / g, and the average pore diameter is 10.4nm.

[0049] A kind of production technology of food additive silica gel of the present invention specifically comprises the following steps:

[0050] (1). Raw material preparation: choose food-grade sodium carbonate and quartz sand, after high-temperature firing to obtain sodium silicate with a modulus of 3.35-3.40, add tap water in a closed melting tank to dissolve and filter, and prepare SiO 2 Sodium silicate solution with a concentration of 14-16%; choose food-grade sulfuric acid, and adjust it to a dilute sulfuric acid solution of 18-22% with treated deionized water.

[0051] (2). Reaction gel making: the above-mention...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com