Casting mold structure for casting tail board of casting machine

A casting mold and tail plate technology, applied in the direction of casting molding equipment, casting mold, casting mold composition, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

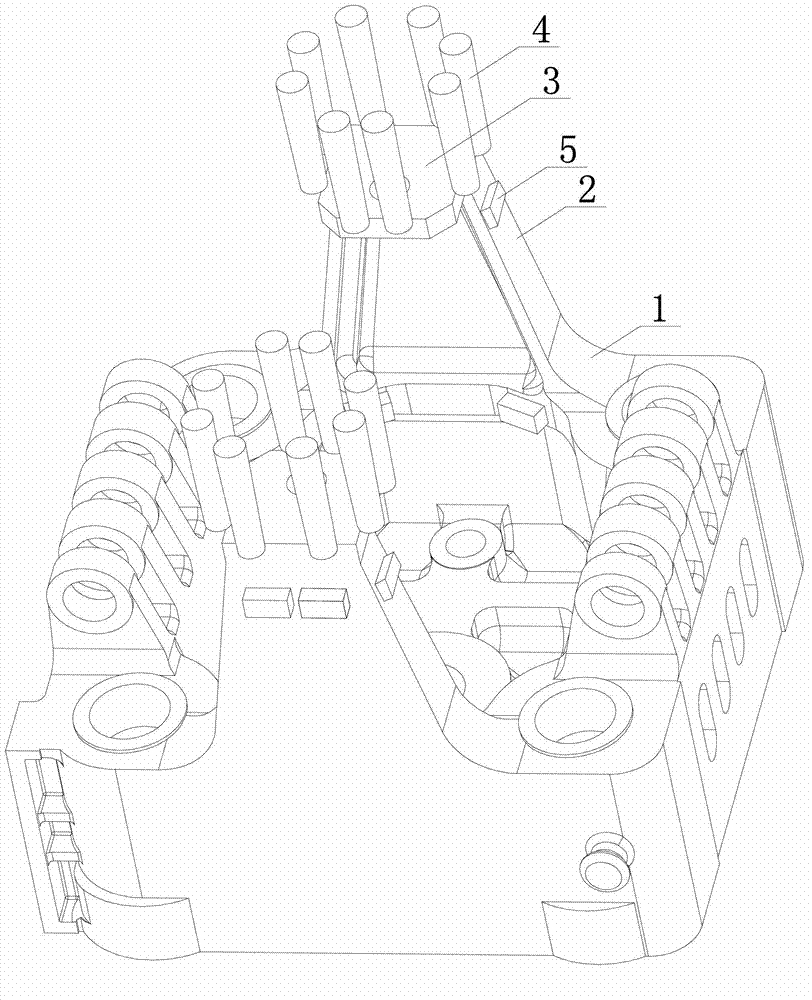

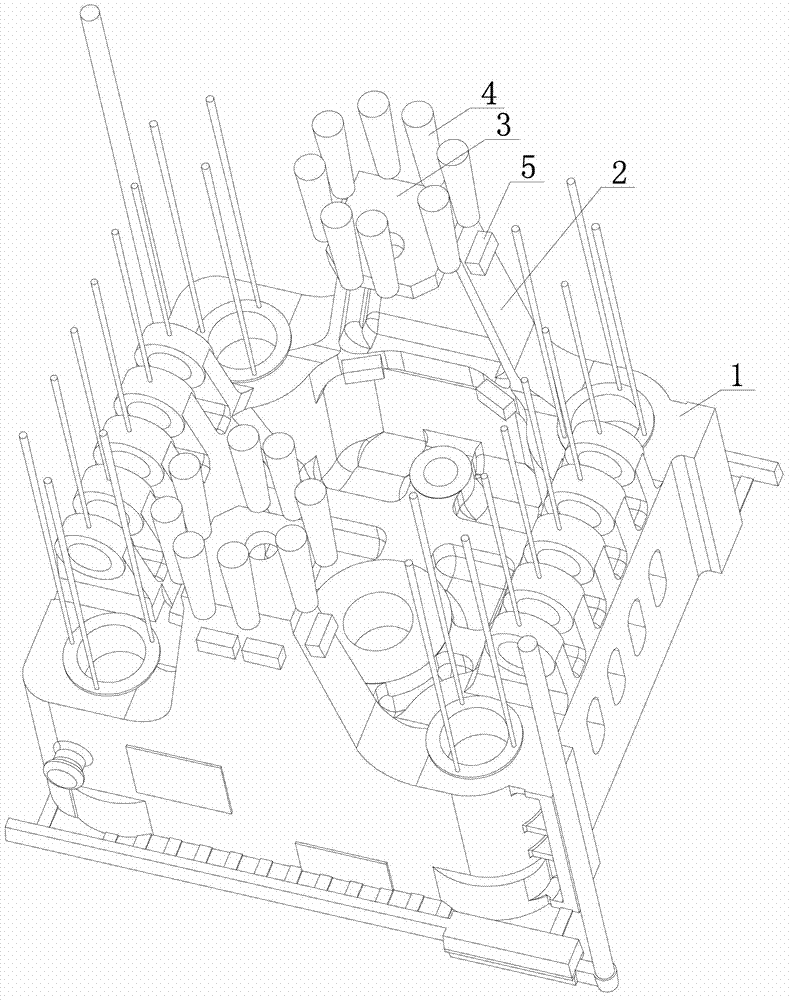

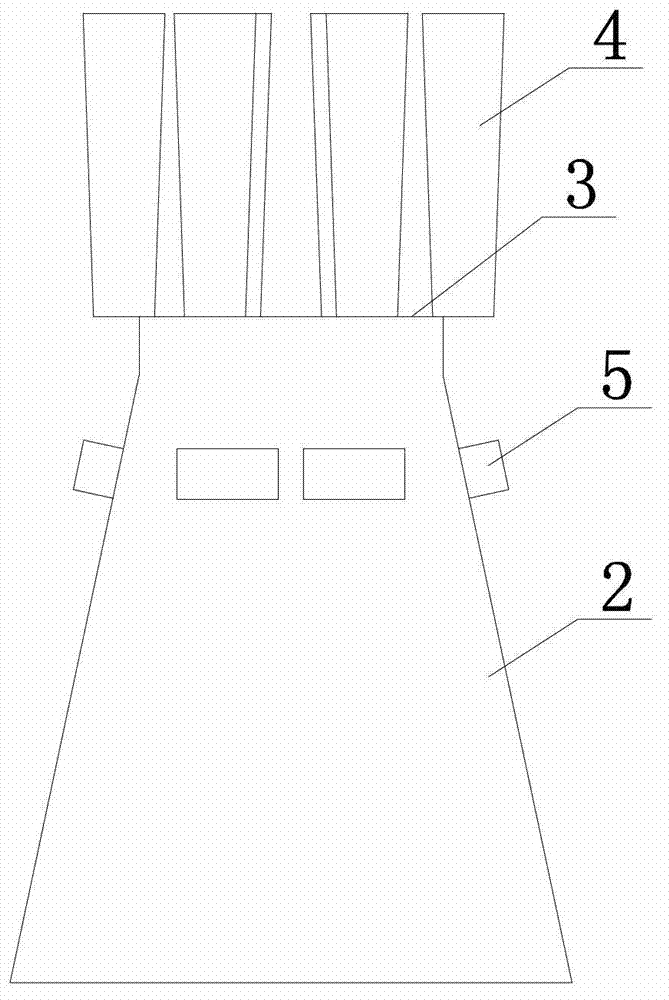

[0012] The present invention will be further described below in conjunction with accompanying drawing.

[0013] The present invention is used for casting the mold structure of the tail plate of the die-casting machine, which includes a mold body 1 for forming the tail plate, and the mold body 1 is provided with a protrusion 2 for forming a thrust seat support seat, and a total of two sets of thrust seat supports Therefore, there are two protrusions 2, the top of the protrusion 2 is a platform 3, and a plurality of edge risers 4 are provided along the circumference of the platform 3, and the distance between the outer surface of the protrusion 2 and the top surface of the platform 3 is 260 mm to 380 mm A plurality of cold irons 5 are arranged in the region, and the plurality of cold irons 5 are distributed along the circumferential direction of the protrusion 2 . The bottom injection casting system is used to inject molten iron from the bottom of the mold body 1 into the inner ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com