Edge wave control method aiming at high-strength steel and work rollers thereof

A control method, technology of work rolls, applied in the direction of manufacturing tools, contour control, rolls, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

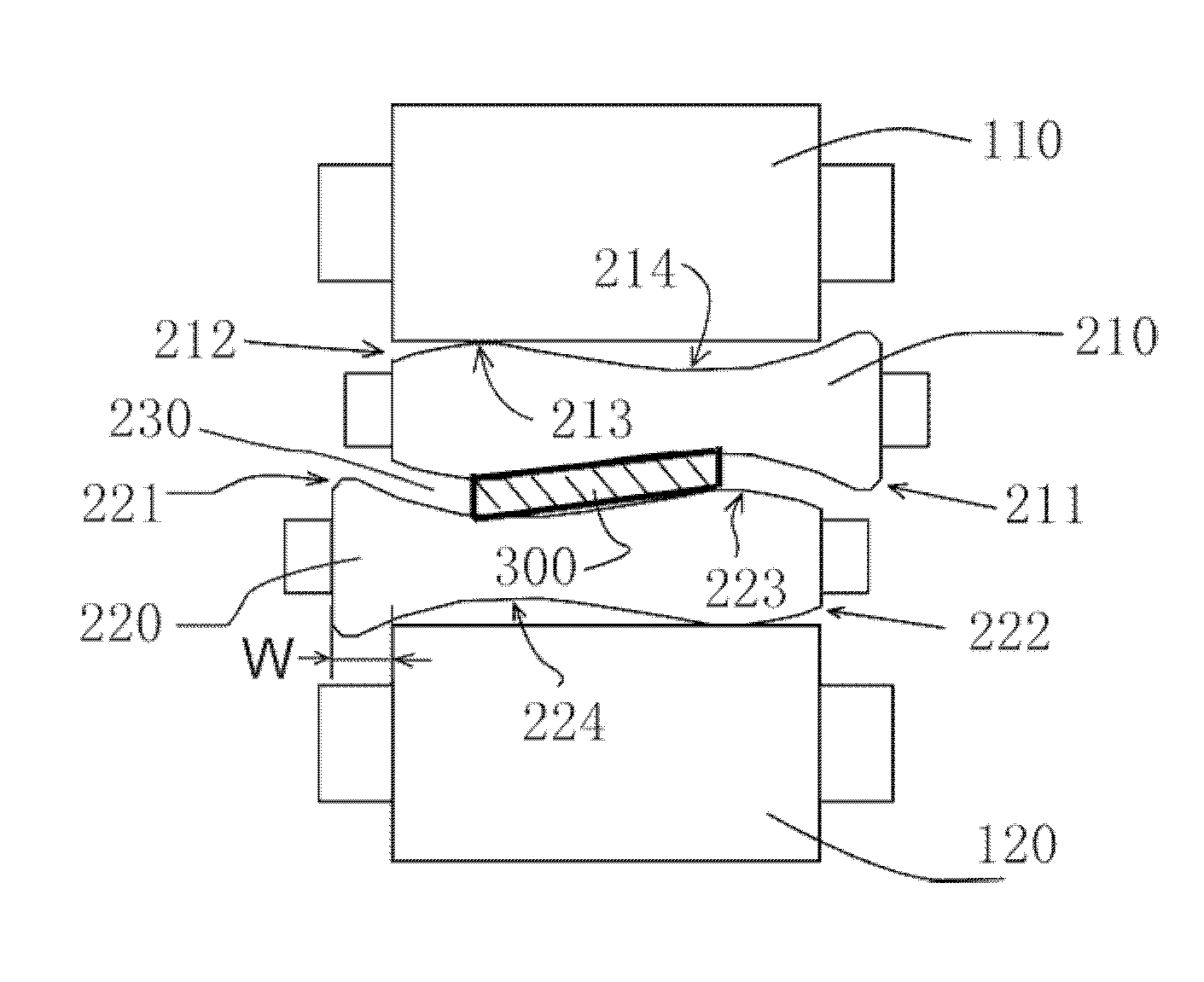

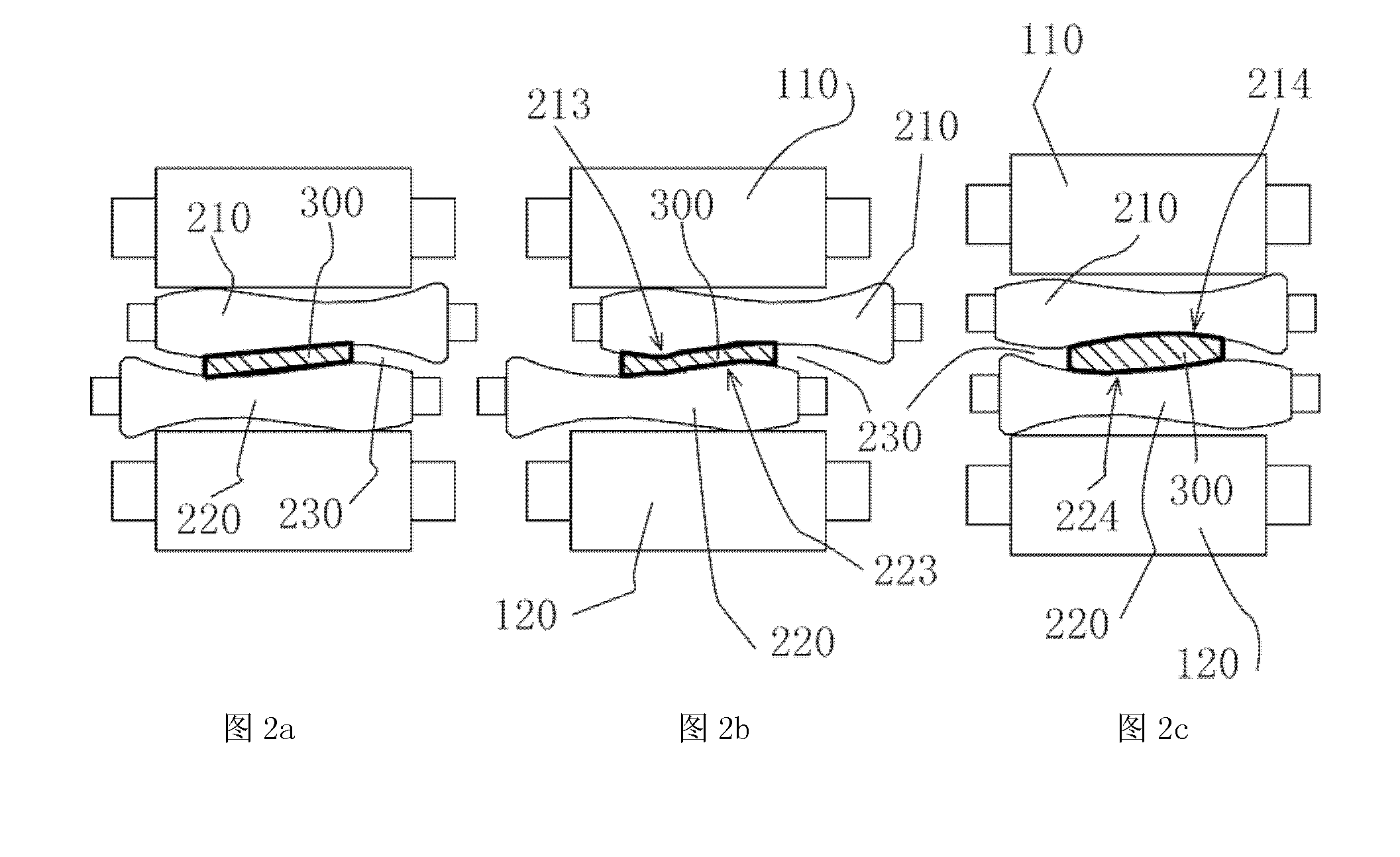

[0032] The present invention proposes a side wave control method for high-strength steel, named SFR (high stiffness and large flexible roll) technology.

[0033] The upper work roll 210 and the lower work roll 220 as the SFR roll are antisymmetrically arranged, and the circumferential surface of each SFR roll that is axisymmetric is processed with a continuous roll-shaped curved surface, such as figure 1 As shown, the roll-shaped curved surface includes a continuous wavy curve, wherein the wavy curve constituting the upper work roll 210 includes crests 213 and troughs 214, and the appearance of the entire work roll 210 is in the shape of an axisymmetric fish-shaped vase with a fish head 212 The portion is flush with the left end of the adjacent backup roll 110; similarly, the end of the fish head 222 of the lower working roll 220 is flush with the right end of the adjacent backup roll 120, and the outer extension of the fish tail 221 protruding from the left end is W It is 5%-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com