Medium-storage ultra-fine pulverized coal preparation system in steel ball mill

A technology of preparation system and coal mill, which is applied in the direction of grain processing, etc., to achieve the effect of improving boiler efficiency, improving economy and safety, and increasing the output of pulverizing system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

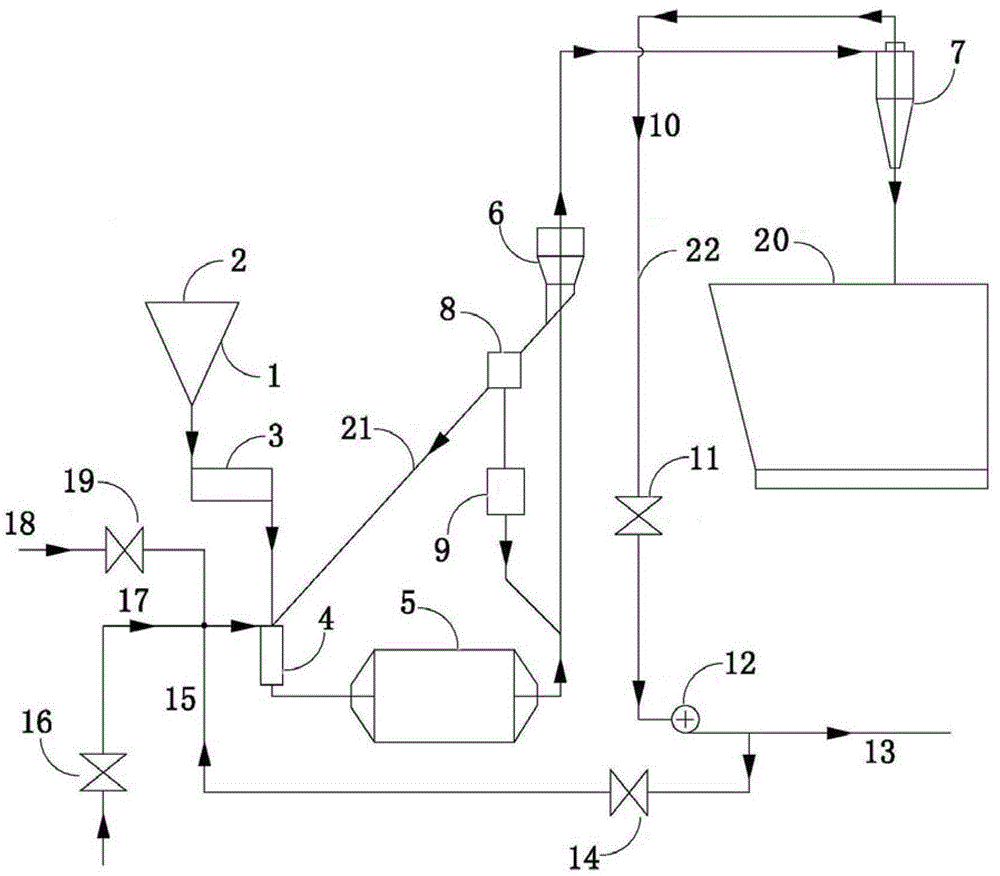

[0028] The present invention will be further described below in conjunction with the accompanying drawings. On the basis of the existing coal pulverization system, the pulverization system is partially modified by adopting high-efficiency dynamic separation technology and multiple classification and grinding technology. Such as figure 1 As shown in , the pulverizer storage type superfine pulverized coal preparation system includes raw coal bunker 1, coal feeder 3, drying pipe 4 with cold air door 19, coal pulverizer 5, dynamic pulverized coal separation device 6, coal For the powder bin 20, as an optimized solution, the dynamic pulverized coal sorting device 6 adopts various pulverized coal sorting technologies to improve the pulverized coal sorting efficiency. The raw coal 2 is transported from the raw coal bunker 1 through the coal feeder 3 and the drying pipe 4 into the coal mill 5, and the pulverized coal pulverized by the coal pulverizer is sorted by the dynamic pulveriz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com