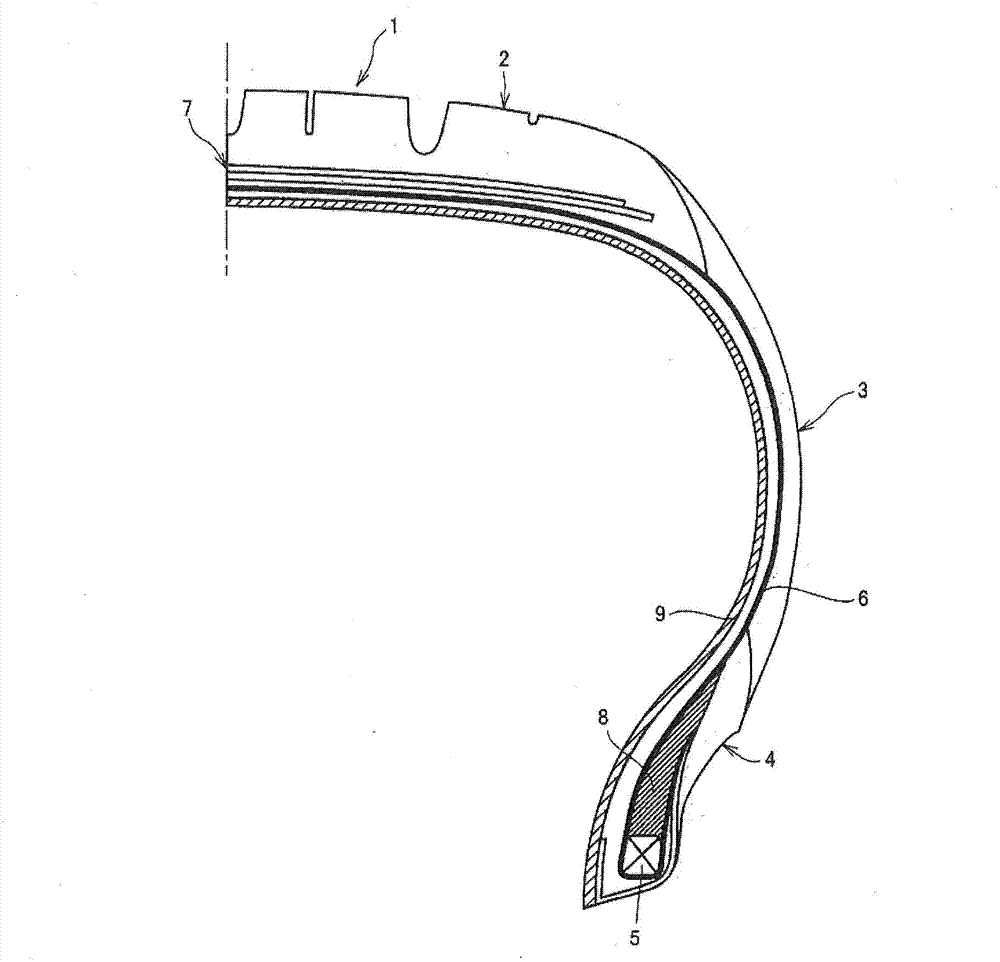

Pneumatic tire

一种充气轮胎、轮胎的技术,应用在充气轮胎、特殊轮胎、轮胎零部件等方向,能够解决轮胎成品变薄等问题,达到耐久性能提高的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

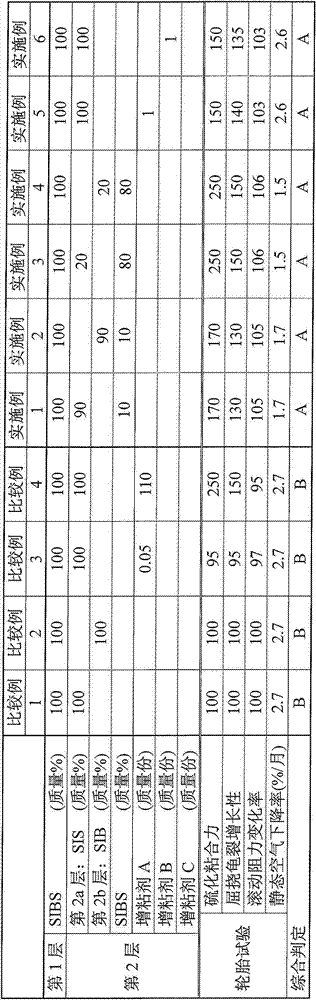

Examples

Embodiment

[0098]

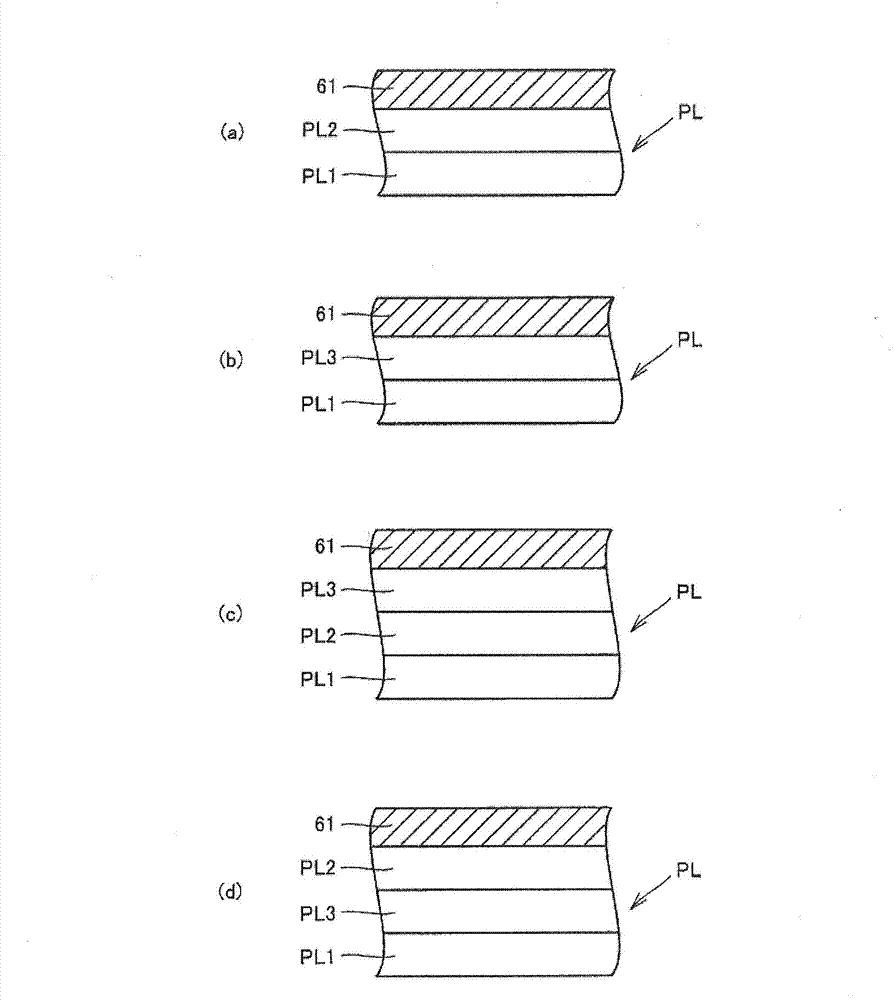

[0099] The thermoplastic elastomers (SIB, SIBS, and SIS) used in the production of the polymer laminate comprising the first layer and the second layer of the present invention are produced as follows.

[0100] [SIB]

[0101] Into a 2 L reaction vessel equipped with a stirrer, 589 mL of methylcyclohexane (dried over molecular sieves), 613 mL of n-butyl chloride (dried over molecular sieves), and 0.550 g of cumyl chloride were added. After cooling the reaction container to -70°C, 0.35 mL of α-picoline (2-picoline) and 179 mL of isobutene were added. Further, 9.4 mL of titanium tetrachloride was added to start polymerization, and the solution was reacted for 2.0 hours while stirring the solution at -70°C. Next, 59 mL of styrene was added to the reaction container, and after continuing the reaction for 60 minutes, a large amount of methanol was added to terminate the reaction. After removing the solvent and the like from the reaction solution, the polymer was dissolv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com