Bamboo string pulling qin manufacturing process

A production process, the technology of stringed qin, which is applied to stringed instruments, instruments, musical instruments, etc., can solve the problems of wasting energy and affecting the protection of the natural environment, and achieve the effects of avoiding wasting energy, not easy to crack and deform, and fast growing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with drawings and embodiments.

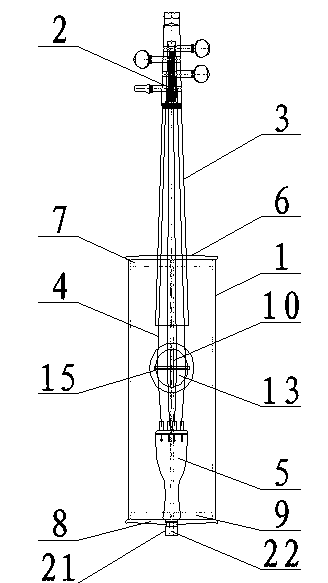

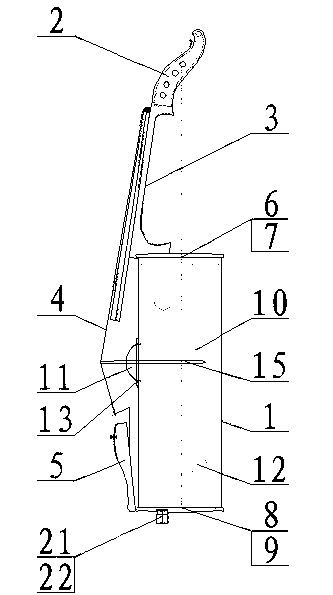

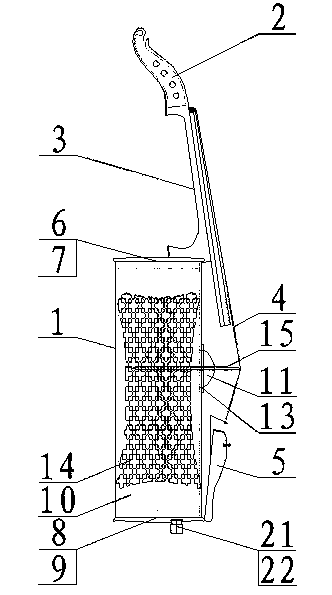

[0035] Figure 1-5 The stringed harp made by the present invention includes a cylinder body 1, a piano head 2, a fingerboard 3, strings 4 and a backplate 5. The piano head 2 is connected to the upper part of the barrel body 1 through the fingerboard 3, the backguy plate 5 is connected to the lower part of the barrel body 1, and a plurality of strings 4 are connected between the piano head 2 and the backguy plate 5; the barrel body 1 is cylindrical and 1. The upper and lower ends are respectively sealed by the upper cover 6 and the lower cover 8. The upper and lower ends of the cylinder body 1 are respectively provided with upper and lower reinforced inner lining plates 7 and 9, and the two ends of the pronunciation middle plate 10 are respectively connected to the upper and lower Reinforced lining plates 7, 9, the upper cover 6 and the lower cover 8 are respectively co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com