Gas pressure detection system, gas pressure detection plug and gas pressure detection plug assembly

A gas and plug technology, applied in the direction of pipes/pipe joints/fittings, passing components, measuring fluid pressure, etc., can solve problems such as failure to detect buried pipelines, damage to pipelines or equipment, and inability to accurately determine the actual situation of pipelines. The effect of improving work efficiency, inspection accuracy, and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

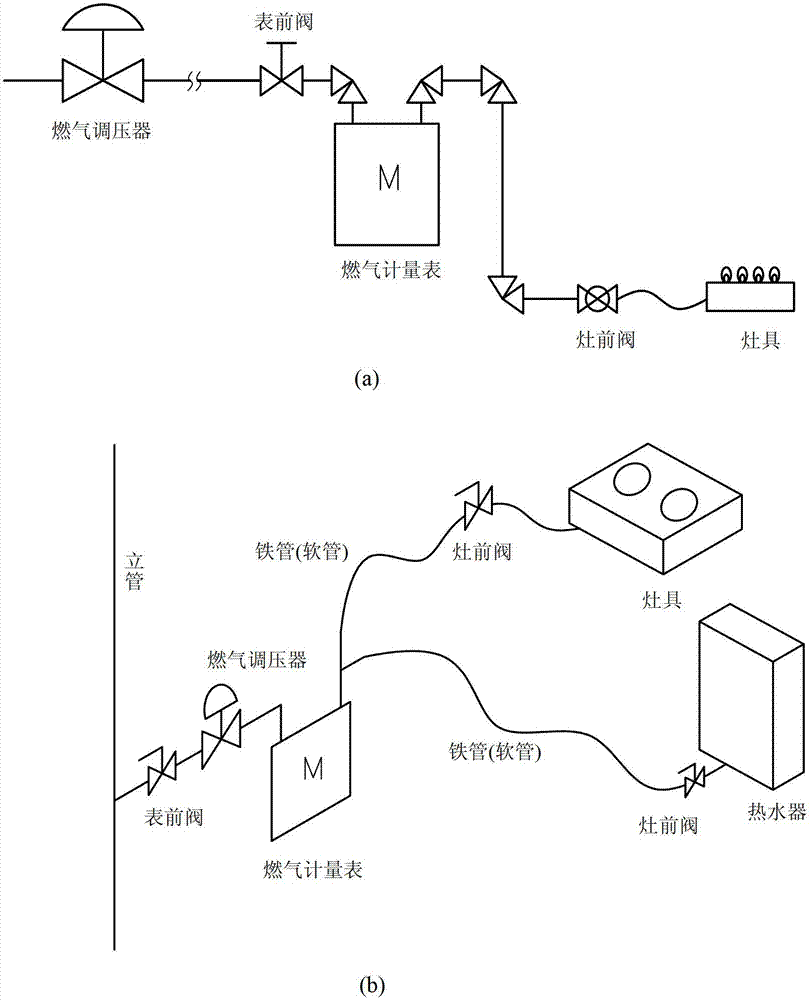

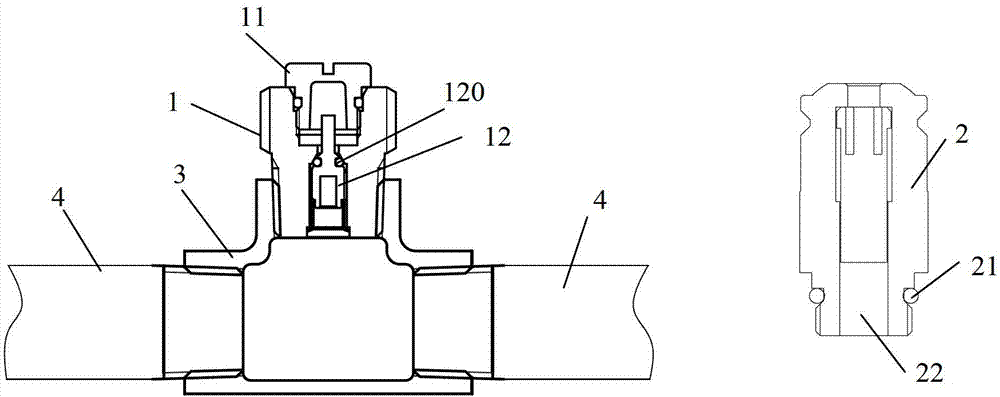

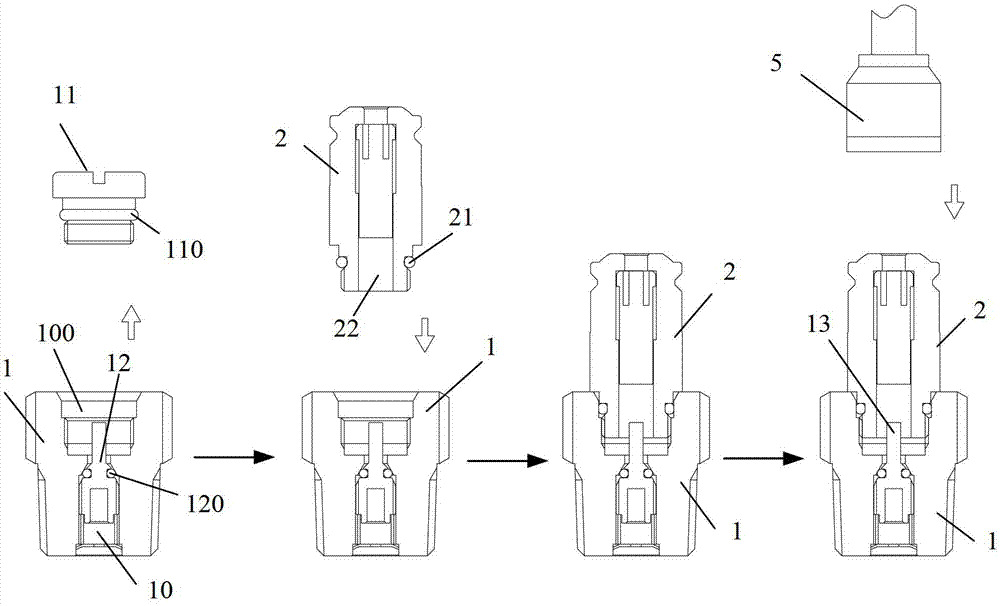

[0025] combine figure 2 and image 3 Embodiments of the gas pressure detection system, the gas pressure detection plug and the gas pressure detection plug assembly of the present invention can be understood.

[0026] exist figure 2 , the seat body of the gas pressure detection plug has been connected to the tee pipe, and the tee pipe is connected in the gas pipeline. Such as figure 2 and image 3 As shown, in the embodiment of the present invention, the gas pressure detection plug assembly includes a seat body 1 suitable for connecting the nozzle of the tee pipe 3 and a quick connector 2, and a gas channel 10 (such as image 3 As shown, up and down through), the middle part of the gas channel 10 is sealed and closed by the check valve 12, and the port 100 of the gas channel 10 of the seat body 1 is also equipped with a head 11. The quick connector 2 has a connecting passage 22, and the lower end of the connecting passage 22 of the quick connector 2 can be tightly conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com