Multi-burner pulverized coal combustion device

A pulverized coal combustion and combustion device technology, applied in the direction of burners, combustion methods, combustion types, etc., can solve the problems of layered combustion with uneven air permeability, obstruction of the combustion process, and large dependence on operating technology to achieve periodic industrial production It is convenient for heating boilers, improves pulverized coal combustion, and strengthens the effect of gas-solid mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Design Fuel:

[0033] Vdaf=38.48%; Car=57.24%; Har=3.81%; 0ar=7.16%; Nar=0.93%; Sar=0.46%; Aar=21.57%; Mar=8.85%; / kg;

[0034] Smoke characteristics:

[0035] Vk0=5.89Nm3 / kg; VR02=1.075Nm3 / kg; VN20=4.661Nm3 / kg; VH200=0.627Nm3 / kg; Vy0=6.363Nm3 / kg;

[0036] Boiler Design Specifications:

[0037] D=10t / h; P=13kgf / cm2; saturated steam; calculated fuel amount: B j =1247.75kg / h

[0038] Air volume distribution

[0039] Design total air volume: Q t =8451.63m 3 / h, of which the primary wind accounts for 25%, which is 2112.91m3 / h, and the rest is secondary wind 6338.725m3 / h;

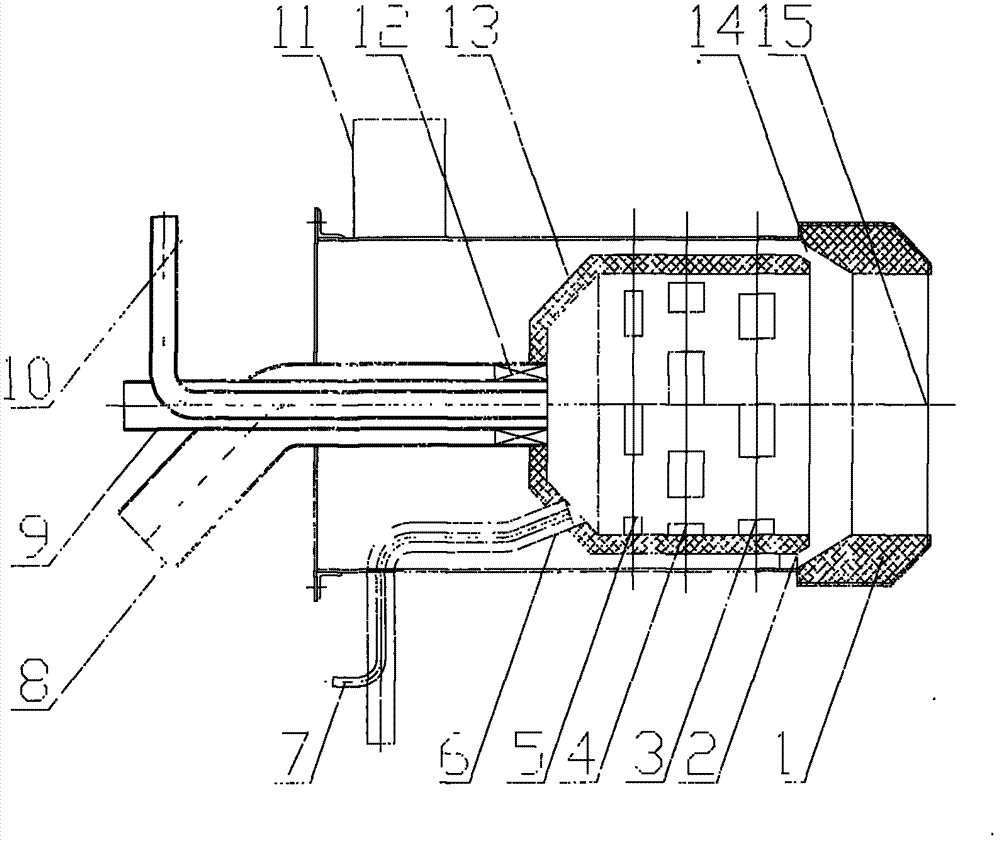

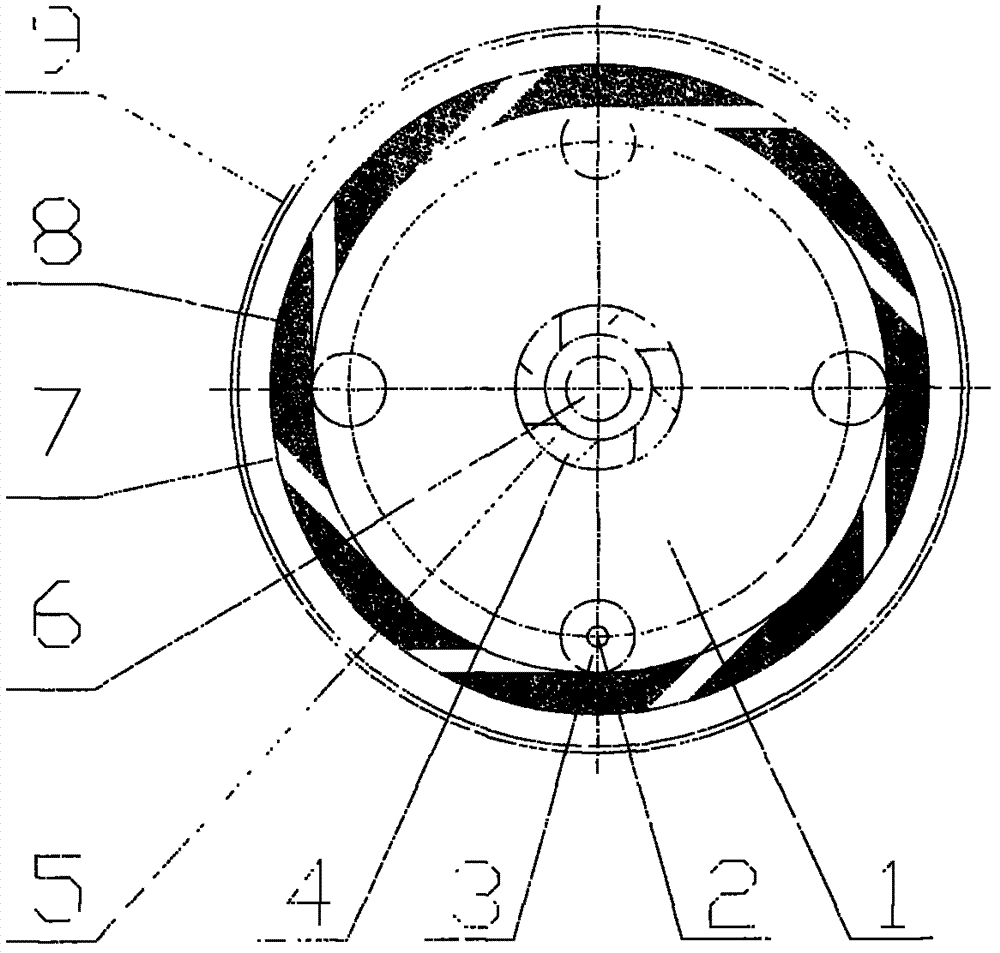

[0040] The main structure

[0041] The diameter of the combustion space of the pre-combustion chamber is 700mm, and the length of the straight section is 600mm. There are 3 tangential secondary air outlets on the straight section. From the burner to the outside, the number of tangential secondary air outlets is 6, 8 and 6, and the circumferential direction is evenly arranged. . The positions f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com