Method for controlling piezoelectric valve positioner capable of changing PWM (pulse-width modulation) duty ratio

A technology of a valve positioner and a control method, which is applied in the direction of valve devices, engine components, mechanical equipment, etc., can solve the problems of large number of forward PWM pulses, slow valve position start process, and long adjustment time, so as to speed up the control process , Accelerate the start-up process of the valve position and reduce the adjustment time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

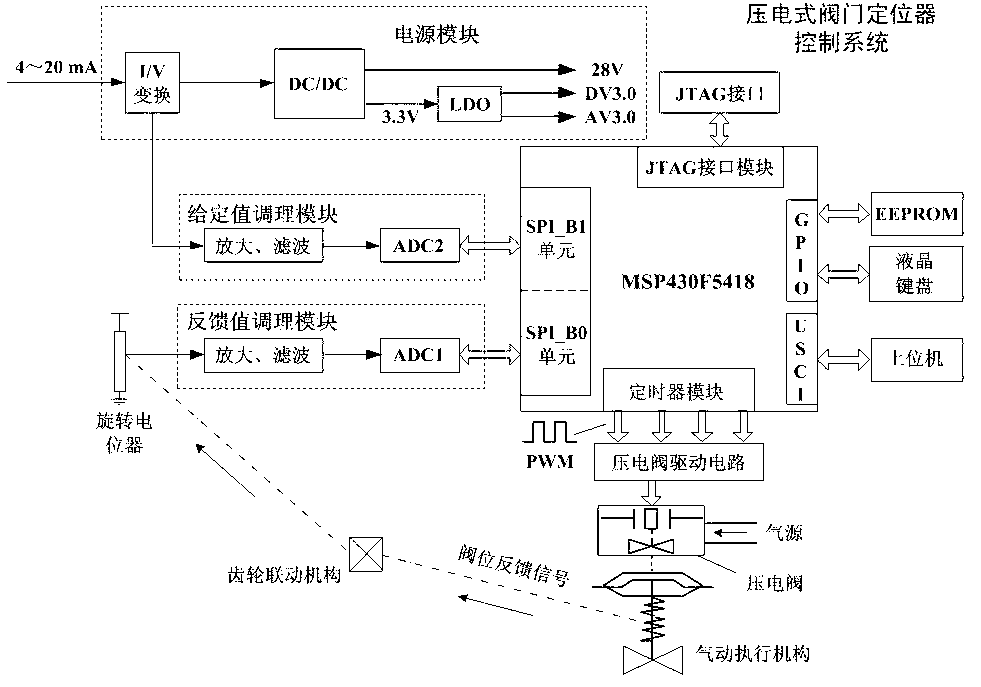

[0025] The present invention will be further described below in conjunction with the accompanying drawings.

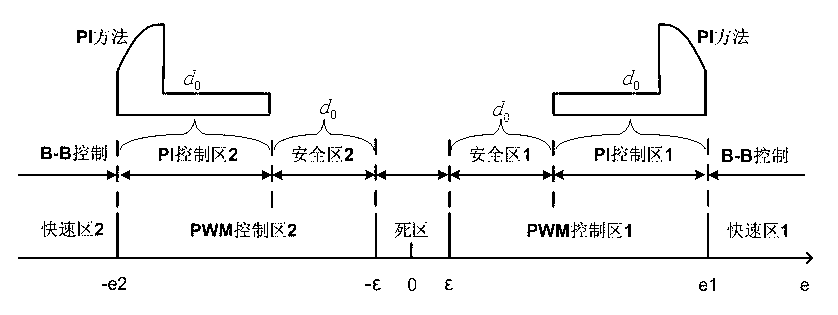

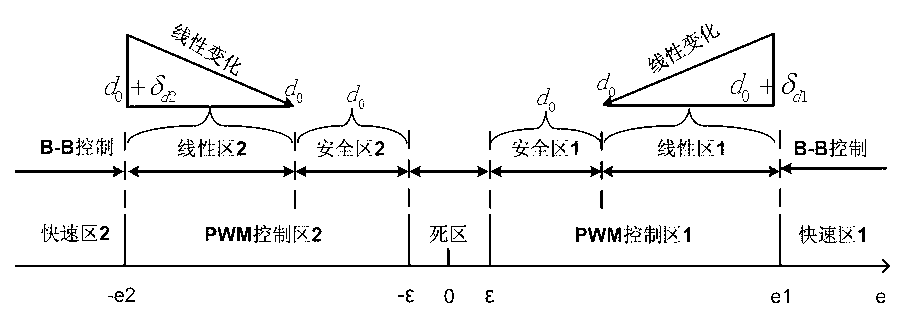

[0026] In the five-step switching method with reverse PWM, according to the size of the valve position error and the error change rate (that is, the valve position speed), the control process is divided into: fast zone, deceleration zone, fine-tuning zone and dead zone, and in the Different control strategies are adopted in corresponding areas. The specific working process is: when the absolute value of the error is large, that is, when the valve position is in the fast zone, B-B control is used to quickly reduce the error; when the absolute value of the error is small, but the valve position speed is large, that is, the valve position is in the falling position In the speed zone, use reverse PWM speed reduction control to quickly reduce the valve position speed; Closely approach the target position; when the valve position smoothly enters the dead zone, the control v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com