Novel desulfurizer packing material for seawater desulfurization and preparation method thereof

A new type of desulfurization and seawater technology, applied in separation methods, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem that the water quality restoration system occupies a large area and the aeration tank occupies a large area , long hydraulic retention time, etc., to achieve the effect of enhancing flue gas desulfurization efficiency, saving design volume, and reducing gas-liquid ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

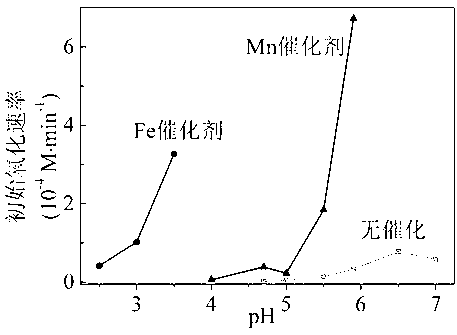

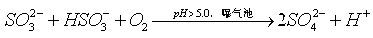

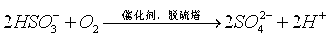

Embodiment 1

[0023] Example 1: The size is Φ30cm, the height is 2m, and the effective volume is 0.5m 3 In the small test device of desulfurization tower, the filling occupies 0.48m 3 The new type of desulfurization tower packing 1# for seawater desulfurization. When preparing the 1# packing, add impregnating liquid and sulfuric acid acid-washed porous Raschig ring in the stainless steel reaction kettle. The porous Raschig ring is 2cm×2cm in size and the composition is SiO 2 , the impregnating solution contains ferrous sulfate 0.02mol / L, manganese sulfate 1.0mol / L, sulfuric acid 0.05mol / L, and contains 4% thermal precipitant, which consists of urea and ammonium acetate. The quality of the impregnating solution and porous Raschig rings The ratio is 1:5, stir, adjust the pH value to 5.0 with sulfuric acid, heat to 40°C, stir at a constant temperature for 24 hours, then heat to 96°C, stir at a constant temperature, precipitate and impregnate for 36 hours, wash with water until the effluent is ...

Embodiment 2

[0024] Example 2: The size is Φ30cm, the height is 2m, and the effective volume is 0.5m 3 In the small test device of desulfurization tower, the filling occupies 0.48m 3 The seawater desulfurization uses a new type of desulfurization tower packing 2#. When preparing the 2# packing, add impregnating liquid and sulfuric acid acid-washed porous Raschig ring in the stainless steel reaction kettle. The porous Raschig ring is 2cm×2cm in size and the composition is SiO 2, the impregnating solution contains ferrous sulfate 0.1mol / L, manganese sulfate 1.0mol / L, sulfuric acid 0.02mol / L, and contains 4.5% thermal precipitant. The components of thermal precipitant are urea, ammonium bicarbonate and ammonium acetate. The mass ratio of Raschig ring is 1:5, stir, adjust the pH value to 5.0 with sulfuric acid, heat to 40°C, stir at constant temperature for 12h, then heat to 96°C, stir at constant temperature, precipitate and impregnate for 40h, wash with water until the effluent is colorless,...

Embodiment 3

[0025] Example 3: The size is Φ80cm, the height is 3m, and the effective volume is 5.5m 3 In the pilot plant of the desulfurization tower, the filling takes up 5m 3 The seawater desulfurization uses a new desulfurization tower packing 3#. When preparing the 3# packing, add impregnating liquid and sulfuric acid acid-washed porous Raschig rings to the stainless steel reaction kettle. The porous Raschig rings are 4cm×4cm in size and composed of SiO 2 The impregnating solution contains ferrous sulfate 0.2mol / L, manganese sulfate 1.0mol / L, sulfuric acid 0.01mol / L, heat precipitating agent 4.5%, heat precipitating agent is urea, impregnating solution and porous Raschig ring mass ratio is 1:4, stir, adjust the pH value to 5.0 with sulfuric acid, heat to 40°C, stir at constant temperature for 18h, then heat to 98°C, stir at constant temperature, precipitate and impregnate for 28h, wash with water until the effluent is colorless, and calcinate at 450°C for 3h. The inlet flue gas conce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com