Stirring shaft of hard ice cream machine

A hard ice cream and stirring shaft technology, applied in the field of stirring shafts, can solve the problems of increasing motor load, increasing motor heat, and not being able to clean the frozen material layer better, achieving good lubrication and wear resistance, sharp cutting edges, and reduced The effect of small load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

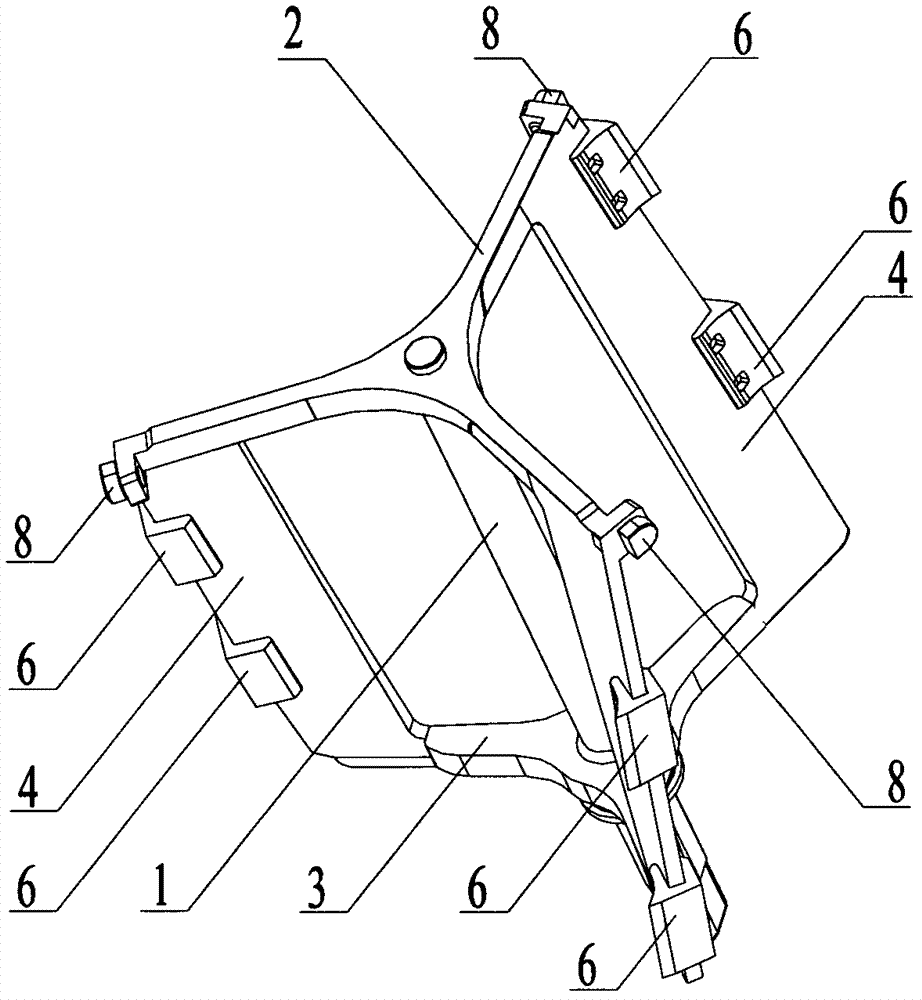

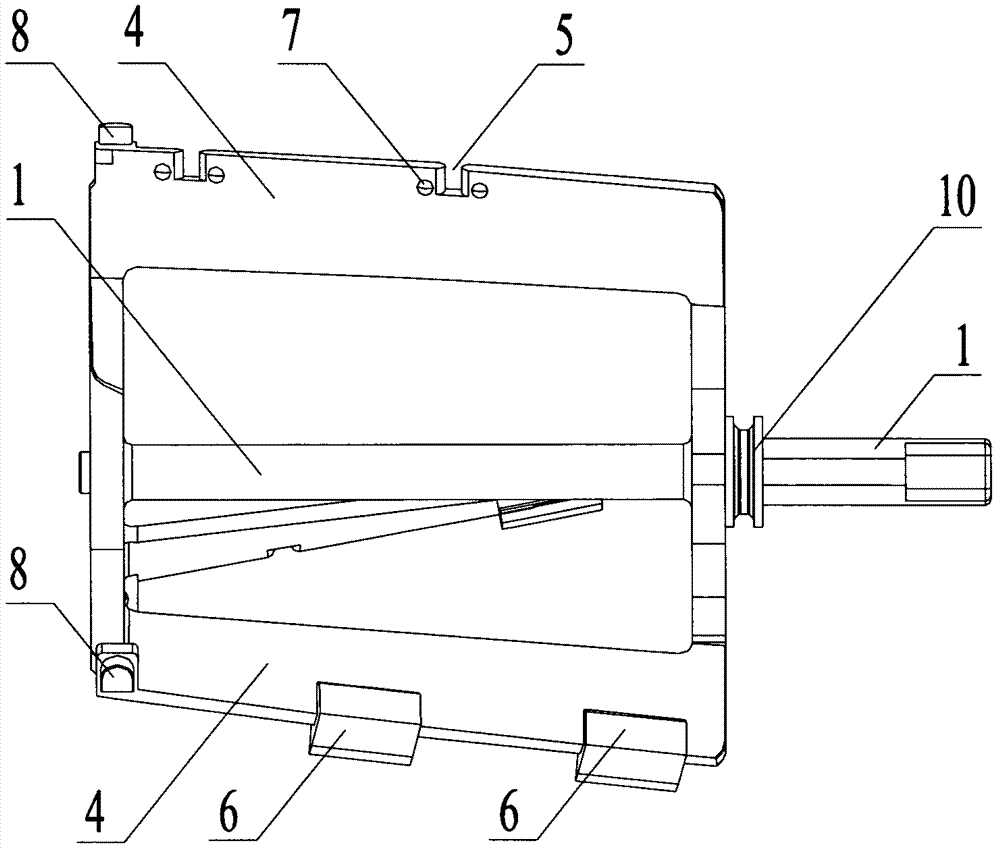

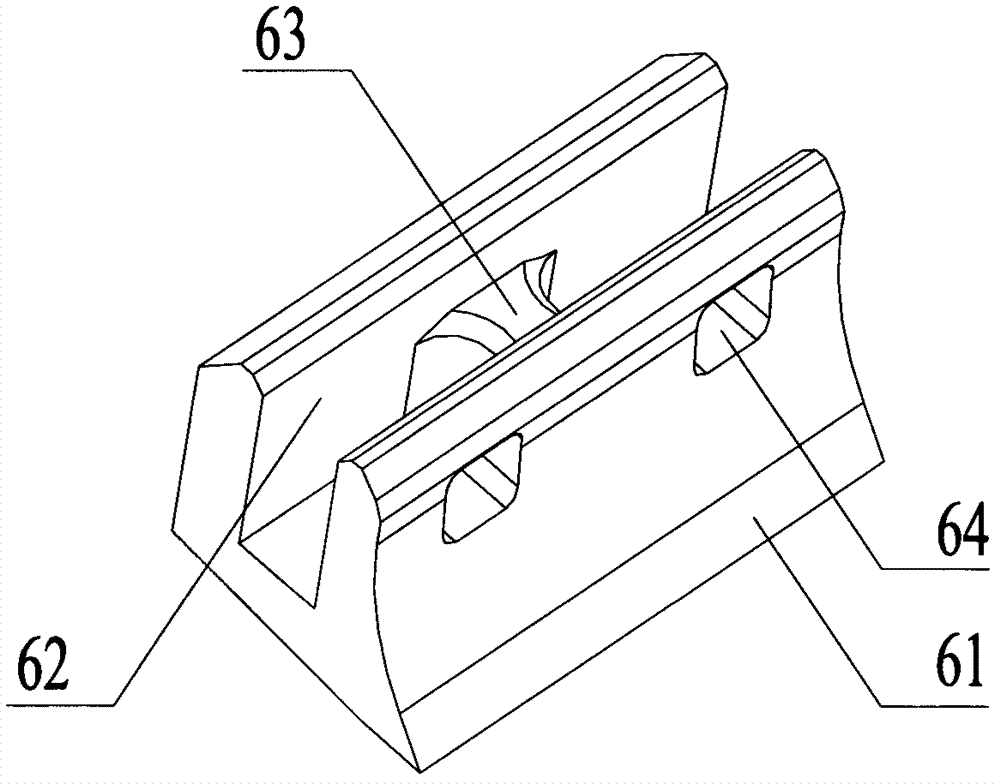

[0025] In this example, figure 1 , figure 2 Shown is the main structure of the stirring shaft. The first bracket 2 and the second bracket 3 are installed on the central shaft 1. The first bracket 2 and the second bracket 3 rotate around the central shaft 1 at an angle of 15°. Each bracket contains three Forks, every two forks are at an angle of 120°, and the stirring blade 4 is installed between the two brackets. During the operation of the stirring shaft of this structure, the ice cream slurry can have a flow tendency, which is beneficial to the discharge from the material. Mouth discharge. But in other embodiments, the central main shaft 10 and the stirring blade 4 can be connected by any known bracket structure, and the stirring blade 4 can be set to two or more pieces according to the number of bifurcations of the bracket, and the two brackets ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com