Extra-high-voltage dry hollow smoothing reactor

A smoothing reactor and reactor technology, applied in the direction of transformer/inductor cooling, transformer/inductor coil/winding/connection, signal inductance without magnetic core, etc., can solve insulator breakage, electric field distortion, discharge and other problems to achieve the effect of increasing the support height, solving the electric field distortion and improving the support strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

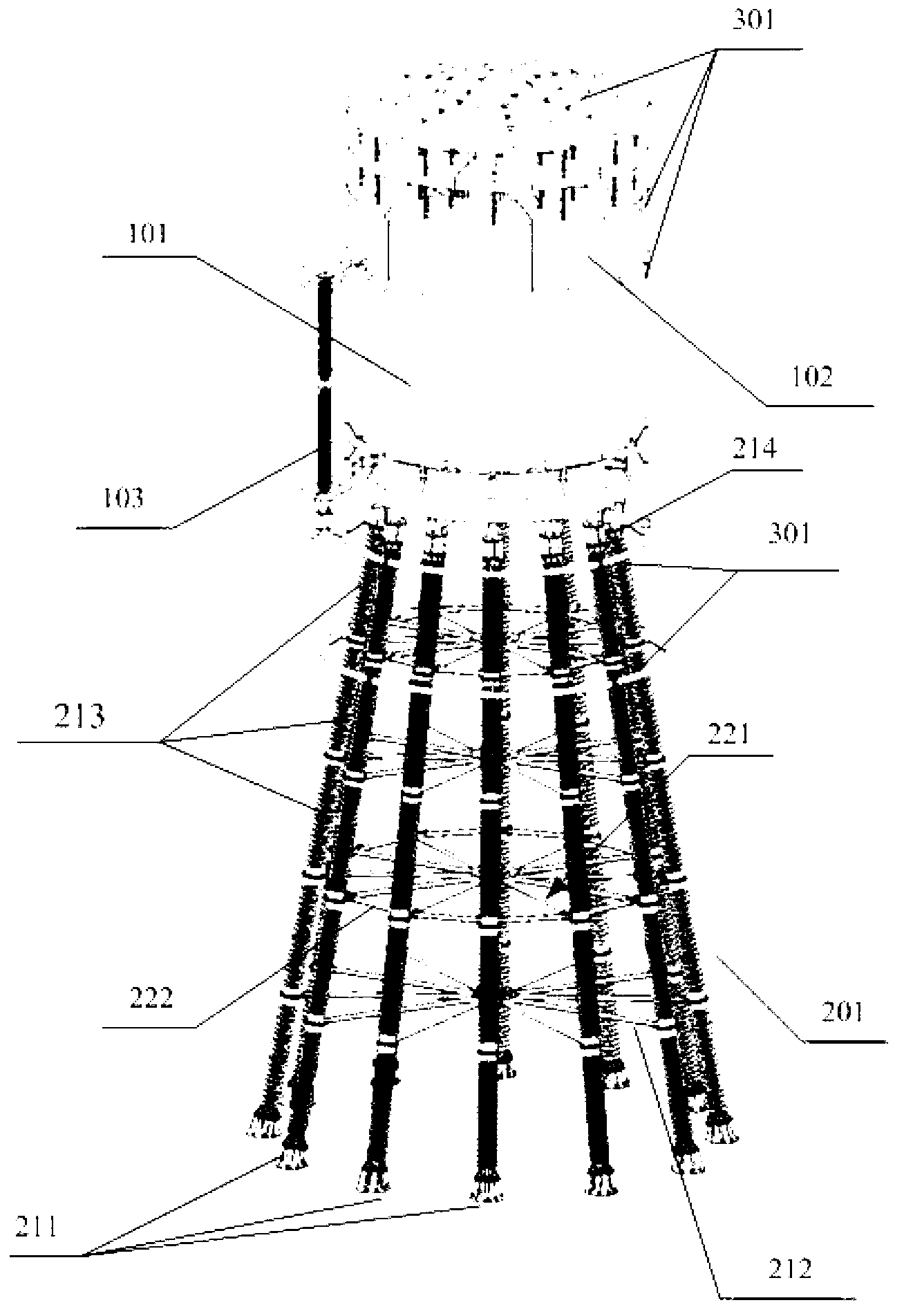

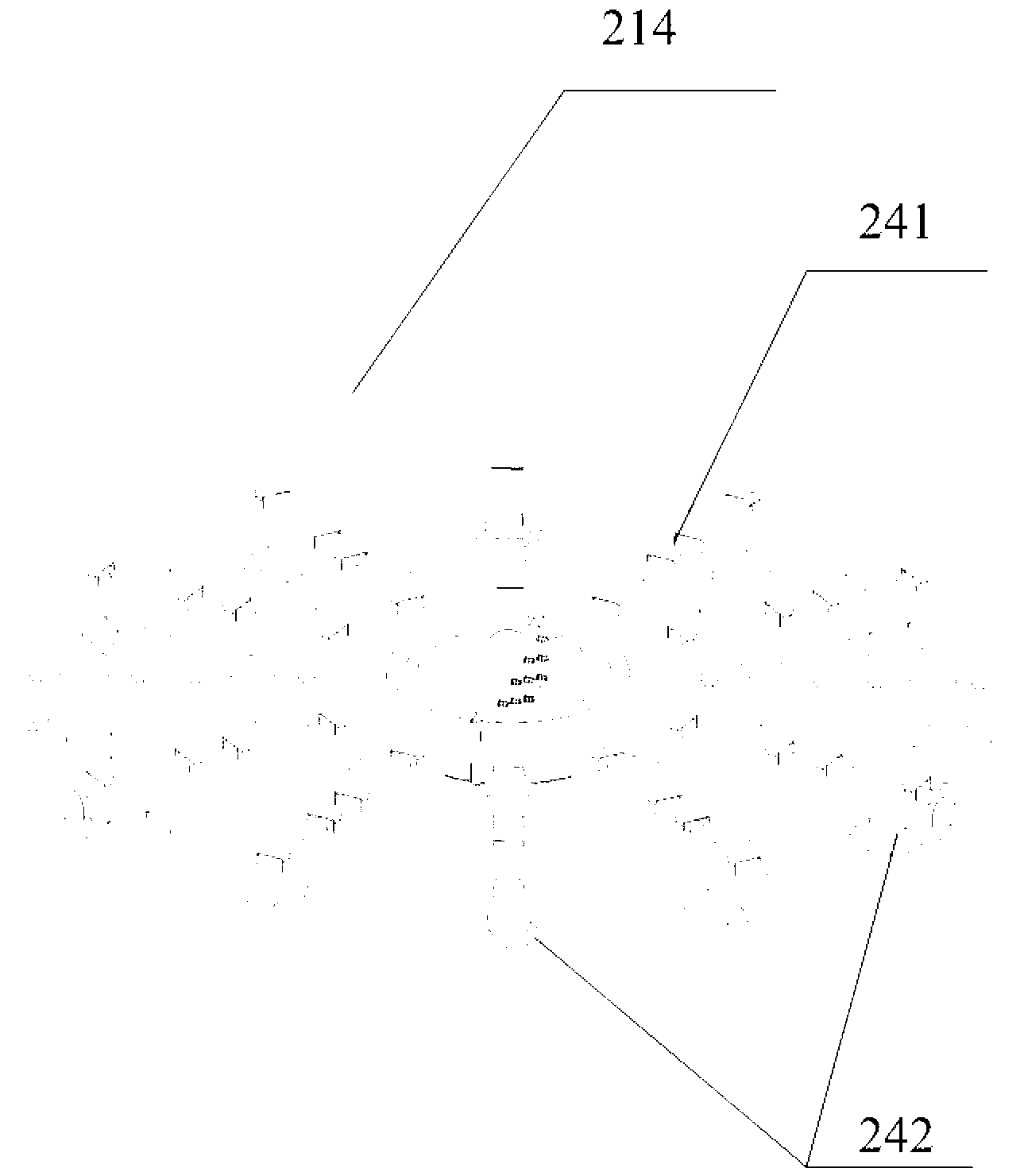

[0050] Figure 5 A structural schematic diagram of the first embodiment of the post insulator supporting structure of the present invention is shown. Such as Figure 5 As shown, the insulating support includes 12 post insulators 211, and each post insulator 211 is perpendicular to the ground. The insulator 213 of each post insulator 211 is a porcelain insulator.

[0051] The bottom of each post insulator 211 has a height-adjustable base plate 215 . The installation height of each post insulator 211 can be guaranteed to be the same by adjusting the base plate 215 .

[0052] This vertical support method occupies a small area, and the cost of the porcelain insulating support is low, which is convenient for popularization.

no. 2 example

[0054] Figure 6 A structural schematic diagram of the second embodiment of the post insulator supporting structure of the present invention is shown. Such as Figure 6 As shown, the insulation support includes 12 post insulators 211, and the included angle between each post insulator 211 and the ground is the same, and both are less than 90° and greater than or equal to 75°, that is, the post insulators 211 adopt an oblique support structure. The insulator 213 of each post insulator 211 is a composite insulator.

[0055] The top of each post insulator 211 has an insulator upper bracket 216 connected to the supporting platform, and the bottom has an insulator lower bracket 217 to improve the supporting strength. The upper bracket 216 of the insulator and the lower bracket of the insulator have the switching function of different link sizes.

[0056] This inclined support method has better seismic performance than vertical supports.

[0057] It can be seen from the above-me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com