Ferrum-based amorphous soft magnetic material and preparation method thereof

A soft magnetic material, iron-based amorphous technology, applied in the direction of magnetic materials, magnetic objects, electrical components, etc., can solve the problems of decreased amorphous formation ability, decreased maximum saturation magnetic induction intensity, unsatisfactory, etc., to achieve low coercive force , large amorphous formation ability, and the effect of high initial permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

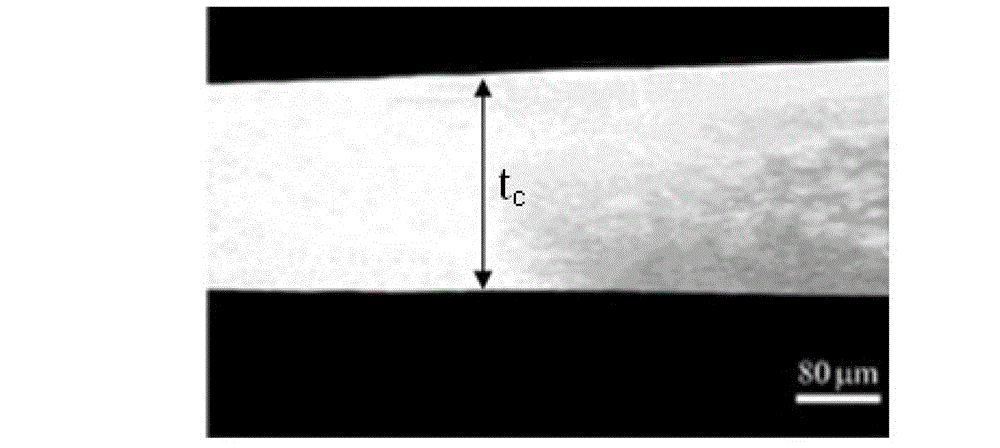

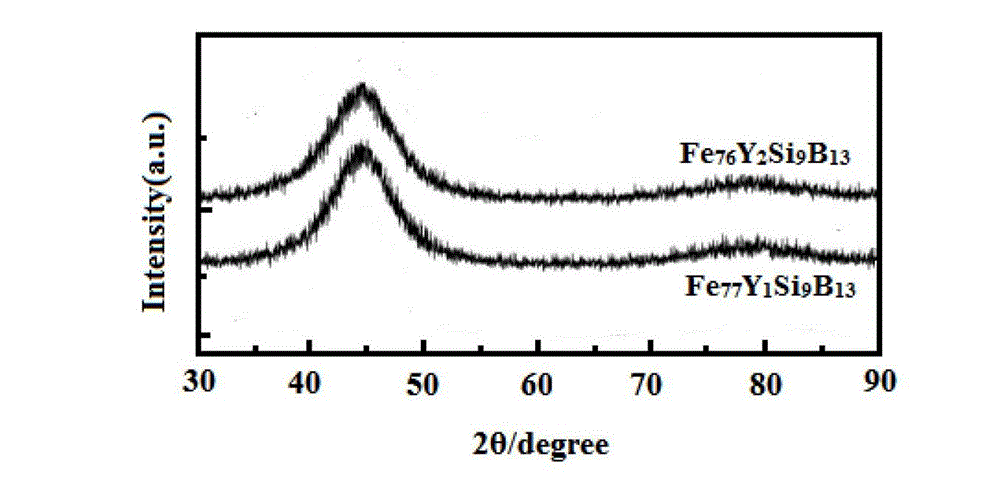

[0036] Iron-based amorphous soft magnetic material Fe 77 Y 1 Si 9 B 13 The preparation method specifically comprises the following steps:

[0037] Step 1: Dosing according to the composition of the above-mentioned iron-based amorphous soft magnetic material, that is, the atomic percentage content, and weighing the ingredients for use;

[0038] Step 2: First, press high-purity Fe, high-purity B, and high-purity Si into Fe 91.18 -B 8.82 (91.18, 8.82 are mass percentages) and / or Fe 79.91 -Si 20.09 (79.91, 20.09 are mass percentages) Preparation of master alloy:

[0039] Evacuate the vacuum chamber of the vacuum induction furnace to 5 x 10 -3Below Pa, fill it with high-purity argon (purity greater than 99.99%) to clean twice, and then melt the master alloy under the protection of high-purity argon (the melting point temperature range of Fe-B master alloy is (1300-1500) ℃, Fe- The melting point temperature range of Si master alloy is (1200~1400)℃), in order to ensure the u...

Embodiment 2

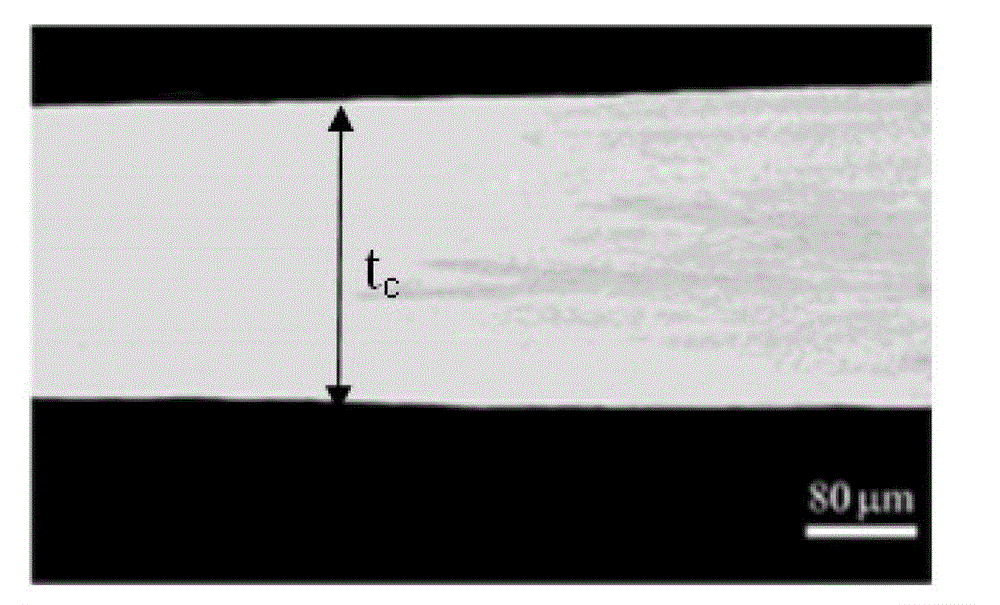

[0044] Iron-based amorphous soft magnetic material Fe 76 Y 2 Si 9 B 13 The preparation method specifically comprises the following steps:

[0045] Step 1: Dosing according to the composition of the above-mentioned iron-based amorphous soft magnetic material, that is, the atomic percentage content, and weighing the ingredients for use;

[0046] Step 2: First, press high-purity Fe, high-purity B, and high-purity Si into Fe 91.18 -B 8.82 (91.18, 8.82 are mass percentages) and / or Fe 79.91 -Si 20.09 (79.91, 20.09 are mass percentages) Preparation of master alloy:

[0047] Evacuate the vacuum chamber of the vacuum induction furnace to 5 x 10 -3 Below Pa, fill it with high-purity argon (purity greater than 99.99%) to clean twice, and then melt the master alloy under the protection of high-purity argon (the melting point temperature range of Fe-B master alloy is (1300-1500) ℃, Fe- The temperature range of the melting point of the Si master alloy is (1200-1400) ℃), in order to...

Embodiment 3

[0056] Iron-based amorphous soft magnetic material Fe 75 Y 3 Si 9 B 13 The preparation method specifically comprises the following steps:

[0057] Step 1: Dosing according to the composition of the above-mentioned iron-based amorphous soft magnetic material, that is, the atomic percentage content, and weighing the ingredients for use;

[0058] Step 2: First prepare high-purity Fe, high-purity B, and high-purity Si as Fe-B and / or Fe-Si to prepare a master alloy, wherein the Fe-B master alloy B is 7wt.%, and the Fe-Si master alloy Si is 15wt. .%:

[0059] Evacuate the vacuum chamber of the vacuum arc furnace to 5×10 -3 Below Pa, fill it with high-purity argon (purity greater than 99.99%) to clean twice, and then melt the master alloy under the protection of high-purity argon (the melting point temperature range of Fe-B master alloy is (1300-1500) ℃, Fe- The melting point temperature range of the Si master alloy is (1200-1400) ℃), in order to ensure the uniformity of the co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com