A kind of galvanized combined brightener and preparation method thereof

A brightener and reactor technology, applied in the field of galvanized combined brightener and its preparation, can solve the problems of narrow bright range in the current density area, easy burning of the electroplating layer, and low cloud point of the brightener, etc., to achieve fast glazing, High cloud point, the effect of expanding brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

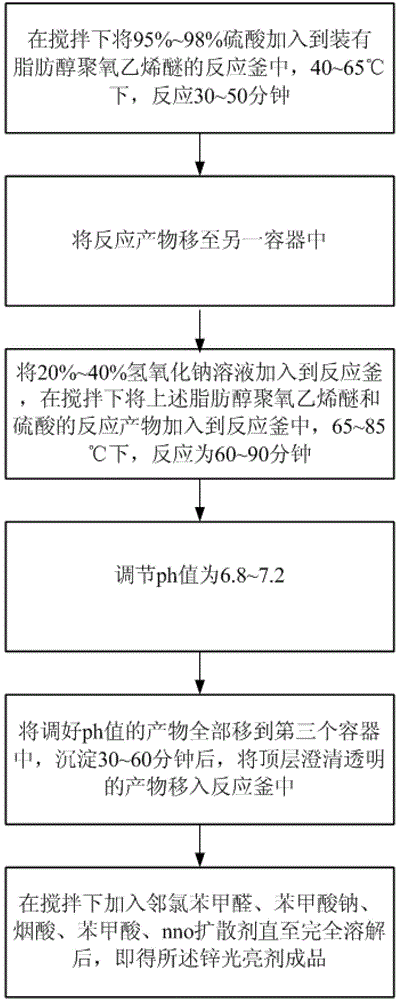

Method used

Image

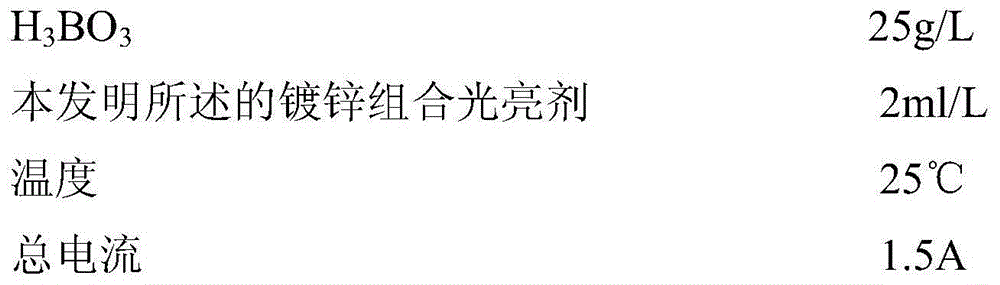

Examples

Embodiment 1

[0031] Put fatty alcohol polyoxyethylene ether with a content of 100kg / t into the reactor, slowly add 95% sulfuric acid with a content of 50kg / t mass concentration under stirring, and the reaction time is 50 minutes. The reaction temperature was controlled at 65°C. After adding sulfuric acid, the material in the reactor is moved to another container with a pump or other tools, and then a 20% sodium hydroxide solution with a mass concentration of 100kg / t is added to the reactor to control The reaction temperature was 65° C. for 60 minutes. After the reaction, the pH value can be adjusted to 6.8 with a small amount of sulfuric acid or sodium hydroxide. Move all the products with a good pH value to the third container for precipitation and separation. After 30 minutes of precipitation, move the clear and transparent product on the top layer into the reaction kettle, and add o-chlorobenzene with a content of 50kg / t once under stirring Formaldehyde, sodium benzoate with a content...

Embodiment 2

[0033] Put the fatty alcohol polyoxyethylene ether with a content of 200kg / t into the reactor, slowly add 96% sulfuric acid with a content of 100kg / t mass concentration under stirring, and the reaction time is 40 minutes. Control the reaction temperature at 50°C. After adding sulfuric acid, use a pump or other tools to move the materials in the reactor to another container, then add 200kg / t of 30% sodium hydroxide solution into the reactor, and stir At the same time, the reaction product of the fatty alcohol polyoxyethylene ether and sulfuric acid was slowly added into the reaction kettle, and the reaction temperature was controlled to be 75° C. for 75 minutes. After the reaction, the pH value can be adjusted to 6.8 with a small amount of sulfuric acid or sodium hydroxide. Move all the products with a good pH value to the third container for precipitation and separation. After 45 minutes of precipitation, move the clear and transparent product on the top layer into the reacti...

Embodiment 3

[0035]Put fatty alcohol polyoxyethylene ether with a content of 300kg / t into the reactor, slowly add 98% sulfuric acid with a content of 150kg / t mass concentration under stirring, and the reaction time is 30 minutes. The reaction temperature was controlled at 40°C. After adding the sulfuric acid, use a pump or other tools to move the material in the reactor to another container, then add a 40% sodium hydroxide solution with a content of 300kg / t into the reactor, and stir At the same time, the reaction product of the fatty alcohol polyoxyethylene ether and sulfuric acid was slowly added into the reaction kettle, and the reaction temperature was controlled at 85° C. for 90 minutes. After the reaction, the pH value can be adjusted to 6.8 with a small amount of sulfuric acid or sodium hydroxide. Move all the products with a good pH value to the third container for precipitation and separation. After 60 minutes of precipitation, move the clear and transparent product on the top la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com