Strong-thixotropy expansion-type high strength chemical blocking agent for blocking water in horizontal well

A horizontal well and expansion-type technology, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems that cannot be applied, cannot meet the water plugging of horizontal wells, and have poor temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

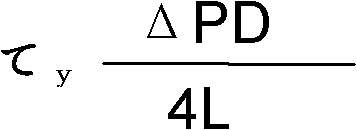

Method used

Image

Examples

Embodiment 1

[0032] Slowly add 0.1 part of cellulose to 33 parts of clean water, stir and dissolve evenly; add 1.9 parts of control agent, 2 parts of nano-calcium carbonate, and 63 parts of ultra-fine cement in turn under the condition of stirring, stir evenly, and put it in a 90°C constant temperature box Conservation 48h.

[0033] The formula loses fluidity 5 minutes after being placed in the oven, and recovers fluidity after vigorous stirring with a glass rod, and initially solidifies after 270 minutes. After solidification, the volume expansion is 1.8%, and the compressive strength is 16.4MPa.

Embodiment 2

[0035] Slowly add 0.15 parts of cellulose to 36.44 parts of clean water, stir and dissolve evenly; add 1.32 parts of control agent, 4.03 parts of nano-calcium carbonate, 58.06 parts of ultra-fine cement in turn under stirring conditions and stir evenly, put it in a 90 ℃ constant temperature box for curing 48h.

[0036] The formula loses its fluidity 8 minutes after being placed in the oven, and can be recovered after vigorously stirring with a glass rod. After 330 minutes, it is initially solidified. After solidification, the volume expansion is 1.4%, and the compressive strength is 13.3MPa.

Embodiment 3

[0038] Slowly add 0.3 parts of cellulose to 39 parts of clean water, stir and dissolve evenly; add 1.4 parts of control agent, 5.3 parts of nano-calcium carbonate, 54 parts of ultra-fine cement in turn under stirring conditions and stir evenly, put it in a 90 ℃ constant temperature box for curing 48h.

[0039] The formula loses its fluidity 15 minutes after being placed in the oven, and can be recovered after vigorously stirring with a glass rod. After 480 minutes, it is initially solidified. After solidification, the volume expansion is 1.2%, and the compressive strength is 11.6MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com