Simple method for manufacturing honeycomb core by textile wastes

A technology of textile waste and honeycomb core, applied in the direction of chemical instruments and methods, lamination auxiliary operations, lamination devices, etc., can solve the problems of many colors, low added value, miscellaneous varieties, etc., and achieve the effect of simple process and easy forming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described below in conjunction with specific embodiments.

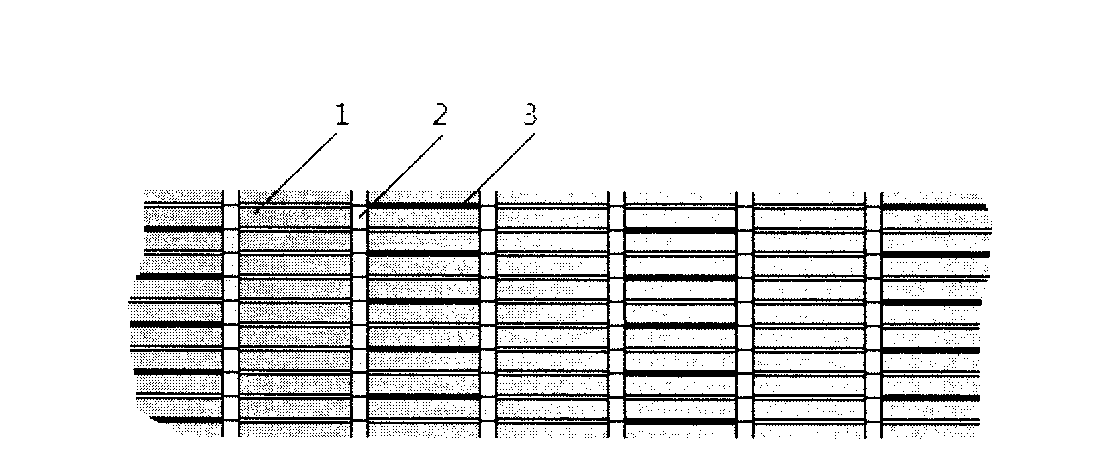

[0017] This embodiment relates to a simple method for making a honeycomb core from textile waste, including the following process steps:

[0018] (1) Fibreboard made of textile waste for fiber felt intervals

[0019] Textile waste treatment: Textile waste is mainly made of ordinary clothing scraps and polypropylene waste silk, polypropylene waste silk is used as adhesive fiber, ordinary clothing corner waste is the main fiber, and the content of polypropylene waste silk is 50%. Considering the different sizes and lengths of the raw materials, especially the polypropylene waste yarn is not easy to open and wind around the cylinder during the tearing process, and the polypropylene waste yarn and the waste spinning fiber are easily mixed unevenly, etc., choose cutting→tearing→mixing Processing technology, the selected textile waste cutting equipment is two rotary cutting machines, fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com