Multi-station machine head for drilling and boring lathe

A multi-station, machine head technology, used in metal processing machinery parts, manufacturing tools, boring/drilling and other directions, can solve the problems of inability to effectively control costs, affect processing accuracy, and low efficiency, and achieve improved and stable Product quality, control processing cost, high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

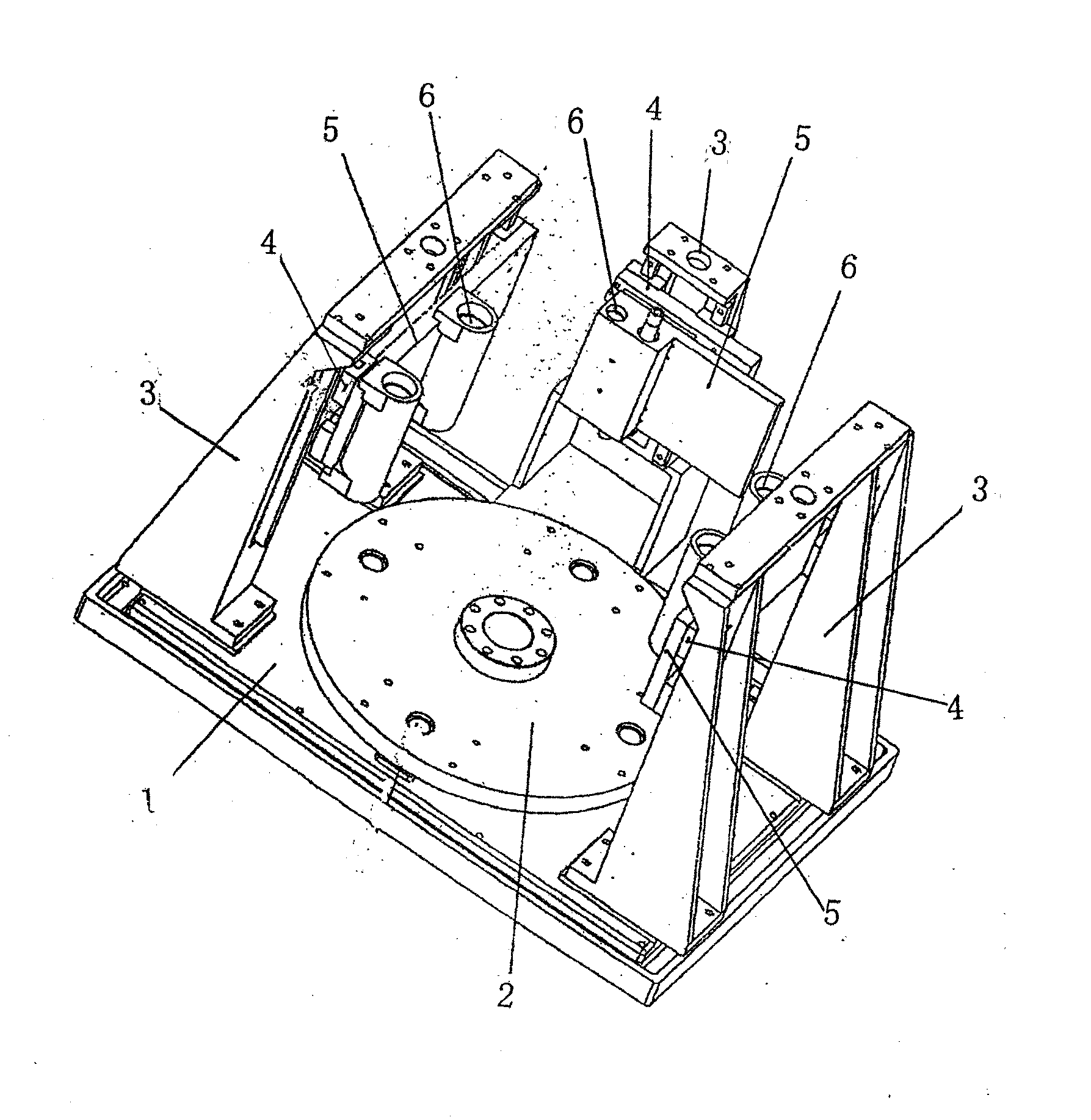

[0011] As shown in the embodiment of the accompanying drawings: the machine head has a rotatable product positioning plate 2 in the middle of the base 1, and several drilling and boring devices for processing products are arranged on the periphery. Drilling, boring device is that slide rail plate 4 is housed respectively on several columns 3, and slide rail plate 4 is provided with slidable drilling, boring processing headstock. The slidable drilling and boring processing car head is provided with several drilling and boring main shaft assemblies 6 on a slidable drilling and boring adjustment plate 5 .

[0012] When specifically implementing the technical solution, the uprights 3 around the base 1 can be arranged on the left, right, and rear sides respectively, and the front side is reserved as the operator's position.

[0013] The working process of the present invention is as follows: the processed product is fixed on the positioning plate 2 in the middle of the base 1. Duri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com