Compound seasoning and preparation method thereof

A technology for compounding seasonings and raw materials, which is applied in the field of food processing to achieve the effects of rich nutrition and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

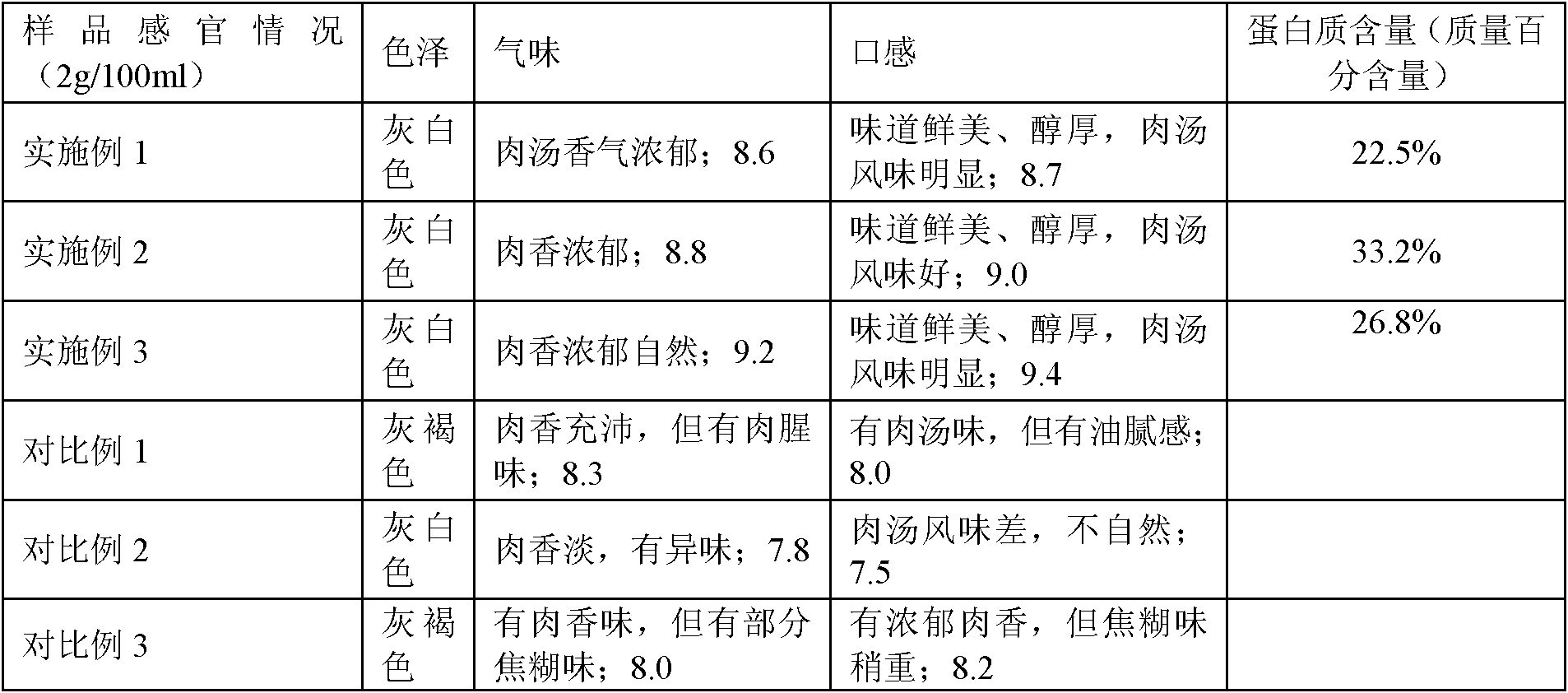

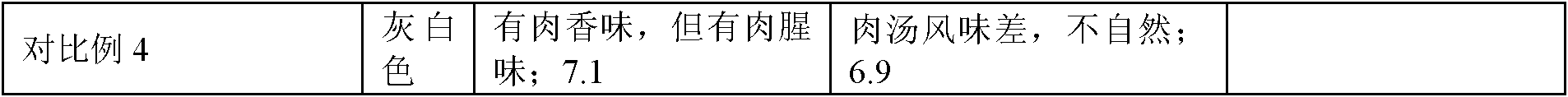

Examples

preparation example Construction

[0019] The compound seasoning of the present invention can be prepared by conventional methods in the prior art. According to a typical embodiment of the present invention, the present invention also provides a preparation method of the compound seasoning. The preparation method comprises the following steps: 1) weighing each component of the raw material of the compound seasoning; 2) performing enzymatic hydrolysis on pork, chicken and beef, and then uniformly mixing with other components of the raw material to perform Maillard reaction , get compound seasoning.

[0020] Preferably, the condition of the enzymatic hydrolysis is: use 0.14% flavor protease of the total weight of the pork, the chicken and the beef to enzymolyze the meat puree in an enzymatic hydrolysis tank at 58°C for 1 hour, and cool down for later use. The enzymatic hydrolysis reaction carried out under this condition, on the one hand, the chicken, pork and beef have been partially enzymatically hydrolyzed, a...

Embodiment 1

[0025] 1) Weigh 230 parts by weight of yeast extract, 70 parts by weight of pork, 50 parts by weight of chicken, 20 parts by weight of beef, 60 parts by weight of table salt, 20 parts by weight of white sugar, 80 parts by weight of monosodium glutamate, 0.7 parts by weight of xanthan gum, malt 90 parts by weight of dextrin, 8 parts by weight of mushroom powder, 12 parts by weight of ginger powder, 6 parts by weight of onion, 1.4 parts by weight of cinnamon powder, and 0.6 part by weight of star anise powder.

[0026] 2) Put pork, chicken and beef into a meat grinder by a certain weight to make a meat paste, pour it into an enzymatic hydrolysis tank, heat up to 90°C to kill the enzyme for 10 minutes, cool down to below 60°C, and use 0.14% of the total meat The flavor protease (Flavourzyme) was used to enzymatically hydrolyze the meat puree for later use. The enzymatic hydrolysis conditions were: temperature 58°C, time 1h.

[0027] 3) Mix the enzymatically hydrolyzed pork, chick...

Embodiment 2

[0029] 1) Weigh 280 parts by weight of yeast extract, 90 parts by weight of pork, 70 parts by weight of chicken, 30 parts by weight of beef, 80 parts by weight of salt, 30 parts by weight of white sugar, 80 parts by weight of monosodium glutamate, 0.9 parts by weight of xanthan gum, malt 110 parts by weight of dextrin, 12 parts by weight of mushroom powder, 18 parts by weight of ginger powder, 10 parts by weight of onion, 1.8 parts by weight of cinnamon powder, and 1.0 part by weight of star anise powder.

[0030] 2) Put pork, chicken and beef into a meat grinder by a certain weight to make a meat paste, pour it into an enzymatic hydrolysis tank, heat up to 90°C to kill the enzyme for 10 minutes, cool down to below 60°C, and use 0.14% of the total meat The flavor protease (Flavourzyme) was used to enzymatically hydrolyze the meat puree for later use. The enzymatic hydrolysis conditions were: temperature 58°C, time 1h.

[0031] 3) Mix the enzymatically hydrolyzed pork, chicken ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com