Opposite electrode structure, SiC photoconductive semiconductor switch (PCSS) and manufacturing methods thereof

A technology of electrode structure and photoconductive switch, which is applied in the direction of final product manufacturing, sustainable manufacturing/processing, and circuits, and can solve the problems of small light-transmitting area and large on-resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

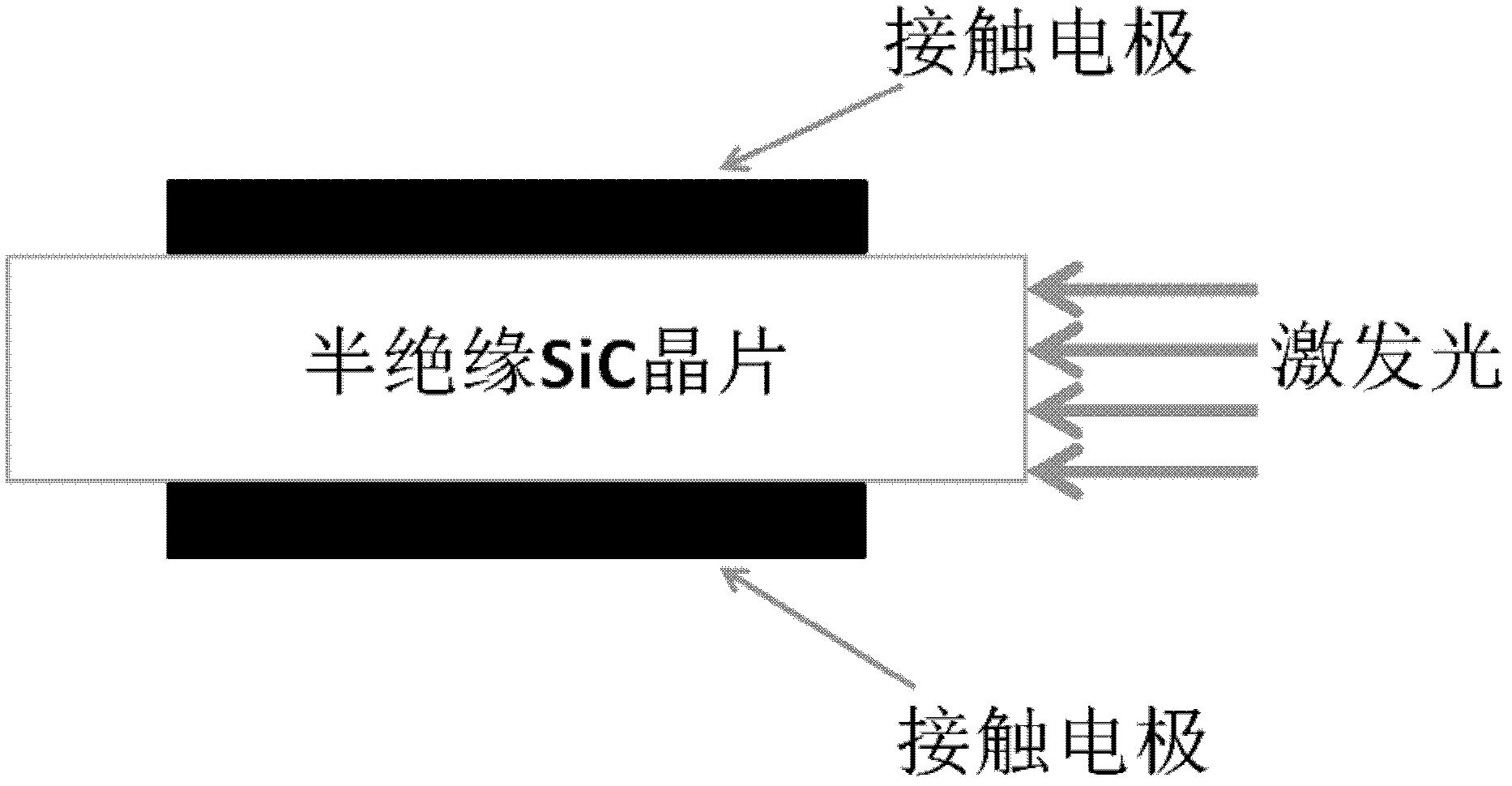

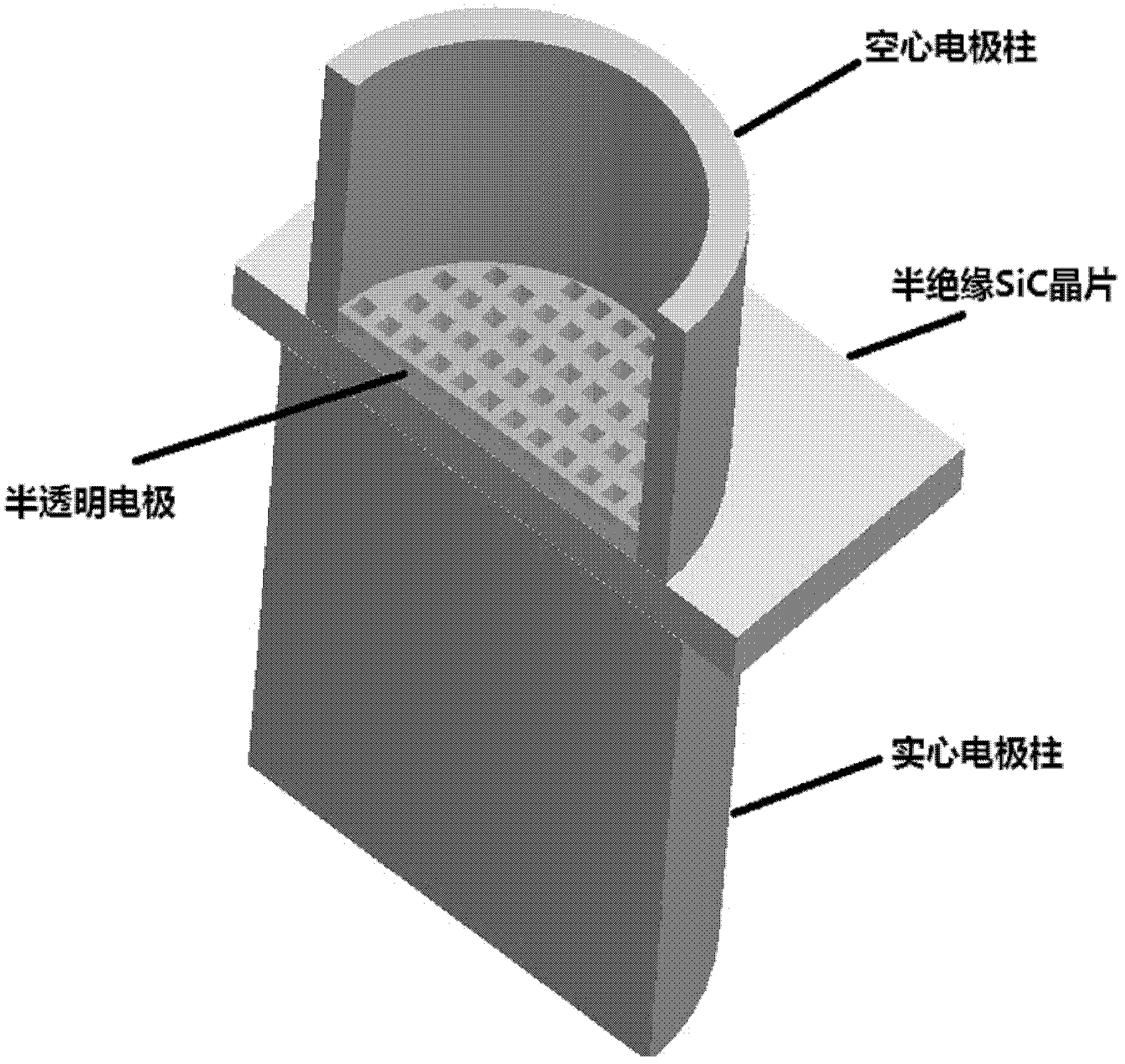

[0042] Embodiment 1 (the present invention)

[0043] A semi-insulating SiC wafer with a (11-20) plane is used, and the wafer is polished using the method described in step (2). After polishing, the thickness of the wafer is 0.4 mm. Wafers were cut into 1.2 cm x 1.2 cm square pieces and cleaned using RCA standard processes. One side of the wafer is plated with Au(500nm) / Pt(100nm) / Ti(100nm) / Ni(50nm) electrodes, the electrodes are circular with a diameter of 10mm, and are rapidly annealed in an Ar atmosphere at an annealing temperature of 1000°C. Annealing time 2 minutes. On the other side of the wafer, a semi-transparent Au(500nm) / Pt(100nm) / Ti(100nm) / Ni(50nm) electrode is plated using a mold, and the electrode is a circle of 8mm. A solid Al electrode post with a diameter of 10 mm is welded to the front side of the wafer, and a hollow Al electrode post with an inner diameter of 7 mm and an outer diameter of 8 mm is welded to the reverse side of the wafer. The switch is encapsu...

Embodiment 2

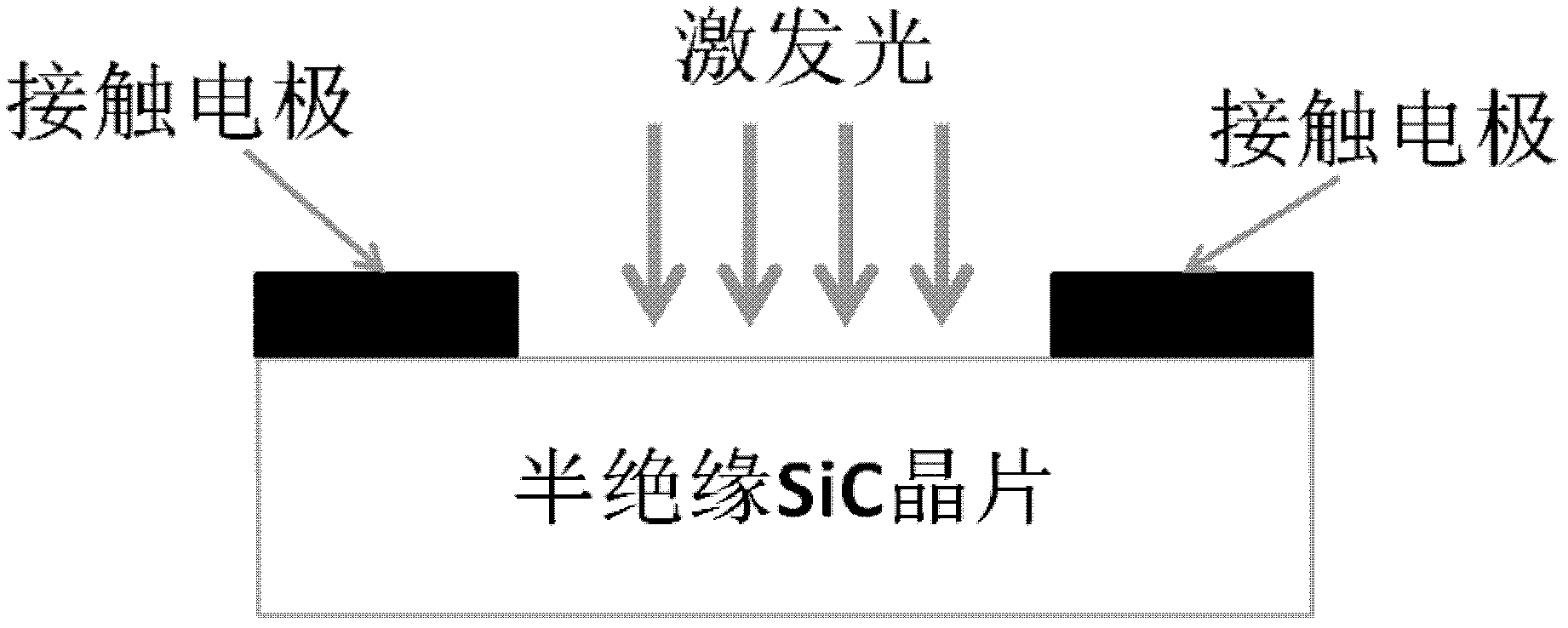

[0045] Embodiment 2 (comparison)

[0046] A semi-insulating SiC wafer with a (11-20) plane is used, and the wafer is polished using the method described in step (2). After polishing, the thickness of the wafer is 0.4 mm. Wafers were cut into 1.2 cm x 1.2 cm square pieces and cleaned using RCA standard processes. Both sides of the wafer are coated with Au(500nm) / Pt(100nm) / Ti(100nm) / Ni(50nm) electrodes, the electrodes are circular with a diameter of 10mm, and are rapidly annealed in an Ar atmosphere at an annealing temperature of 1000°C. Annealing time 2 minutes. Solid Al electrode posts with a diameter of 10 mm were welded to the front and back of the wafer. The switch is encapsulated using a Teflon mold. The packaging material uses epoxy polymer insulating material, mixed with 15% BaTiO 3 , Under 0.5Pa air pressure, degas the encapsulated switch to extract the air bubbles in the encapsulation material.

[0047] Excited with 532nm light, the energy is 5mJ per pulse, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com