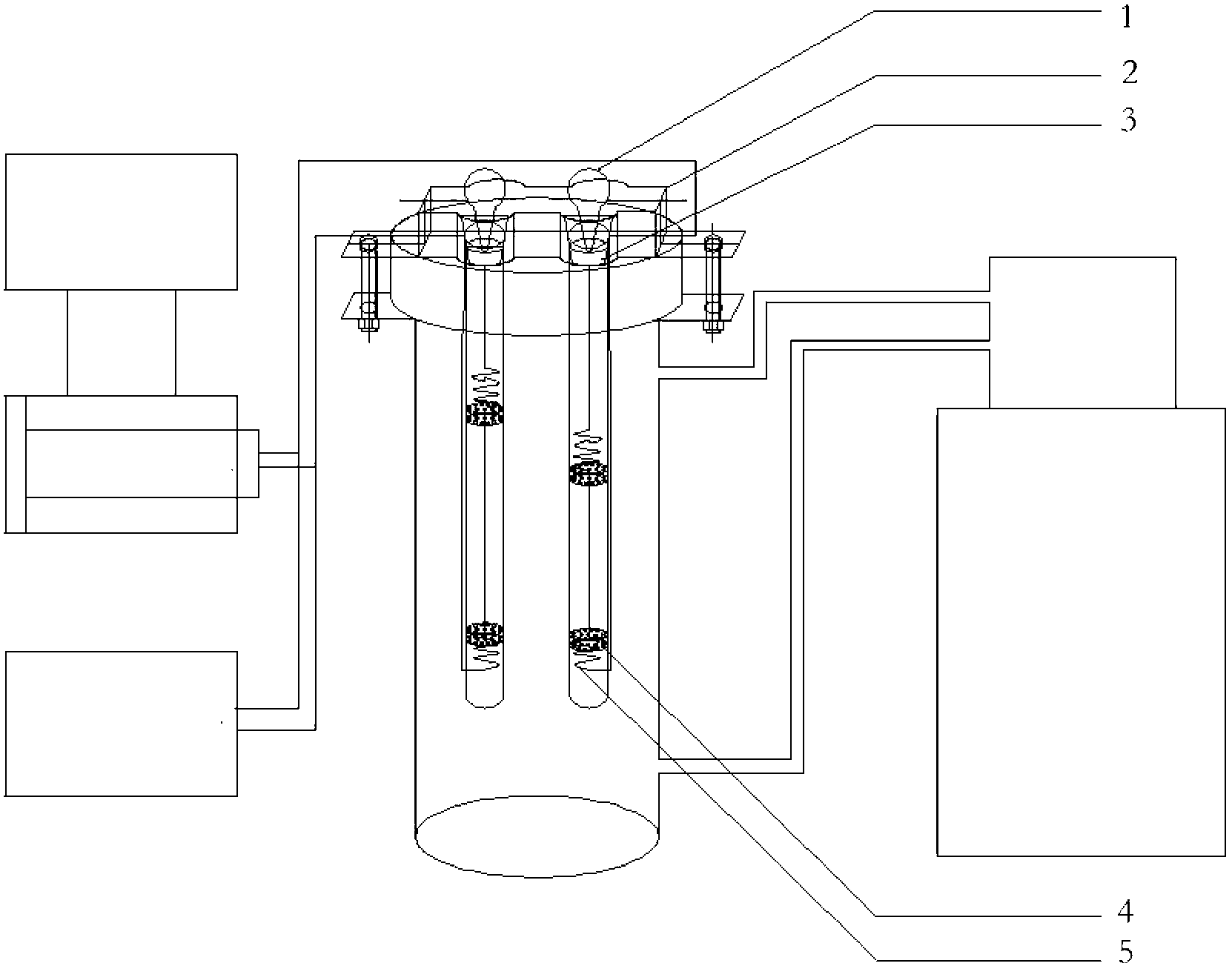

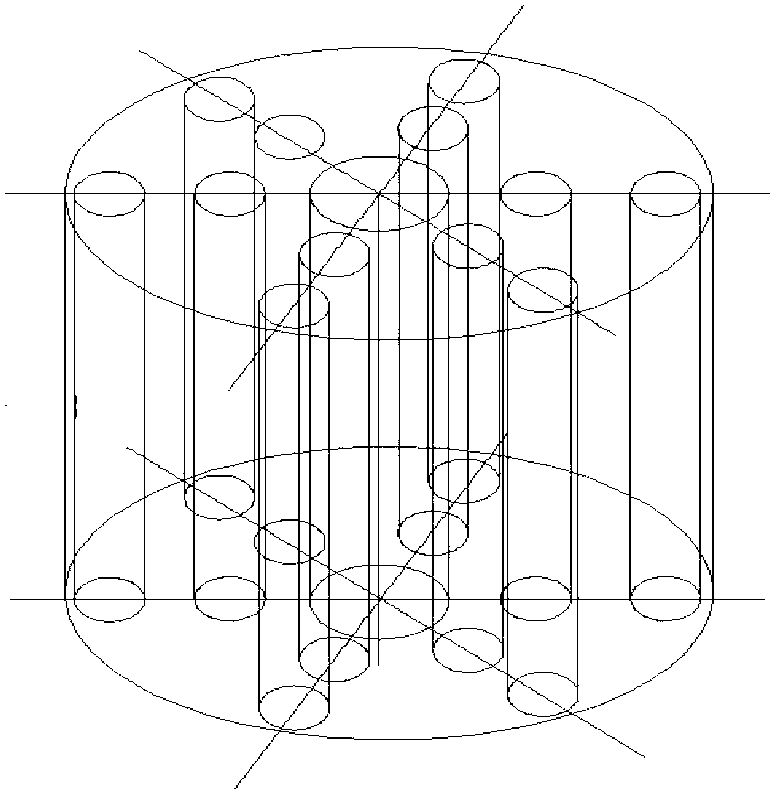

Device for measuring liquid heat conductivity coefficient based on transient dual-hot-wire method

A technology of thermal conductivity and hot wire method, which is applied in the field of devices for measuring the thermal conductivity of liquids based on the transient double hot wire method, can solve the problems of deviation of test results, poor accuracy of test results, affecting the temperature field distribution in the thermal conductivity pool, etc. Guaranteed distribution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention can be further illustrated by the following examples. The examples are intended to illustrate rather than limit the present invention. Any person of ordinary skill in the art can understand that these embodiments do not limit the present invention in any way, and can make appropriate modifications and parameter transformations without departing from the essence of the present invention and departing from the scope of the present invention.

[0013] Example 1:

[0014] Use the rubber cap at the upper end of the glass tube to absorb 5% dilute acetone solution to clean the welding platinum wire and the stains on the surface of the platinum wire and the inner wall of the glass tube during the operation. The same method is used to suck and press out distilled water, and repeat about 20 times to clean the acetone solution remaining on the hot wire and the inner wall of the glass tube in the previous step. Put the glass tube in the heat preservation barrel, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com