Heat exchange plate for plate-type evaporator

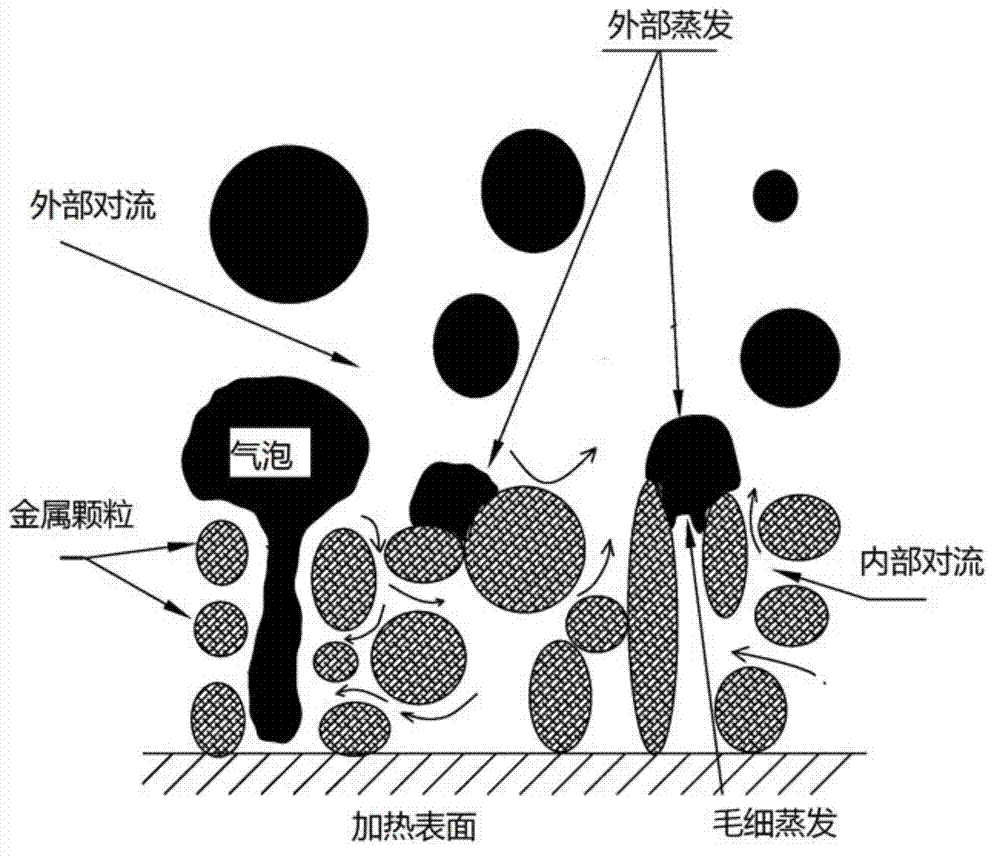

A plate evaporator and heat exchange plate technology, which is applied in the field of heat transfer, can solve the problem of limited effect of enhancing the heat transfer of boiling phase, and achieve the effect of increasing the total heat transfer coefficient, reducing the degree of superheat and strengthening the heat transfer of boiling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific implementation of the present invention will be further described below in conjunction with the accompanying drawings and examples. The following examples are only used to illustrate the technical solutions of the present invention more clearly, but not to limit the protection scope of the present invention.

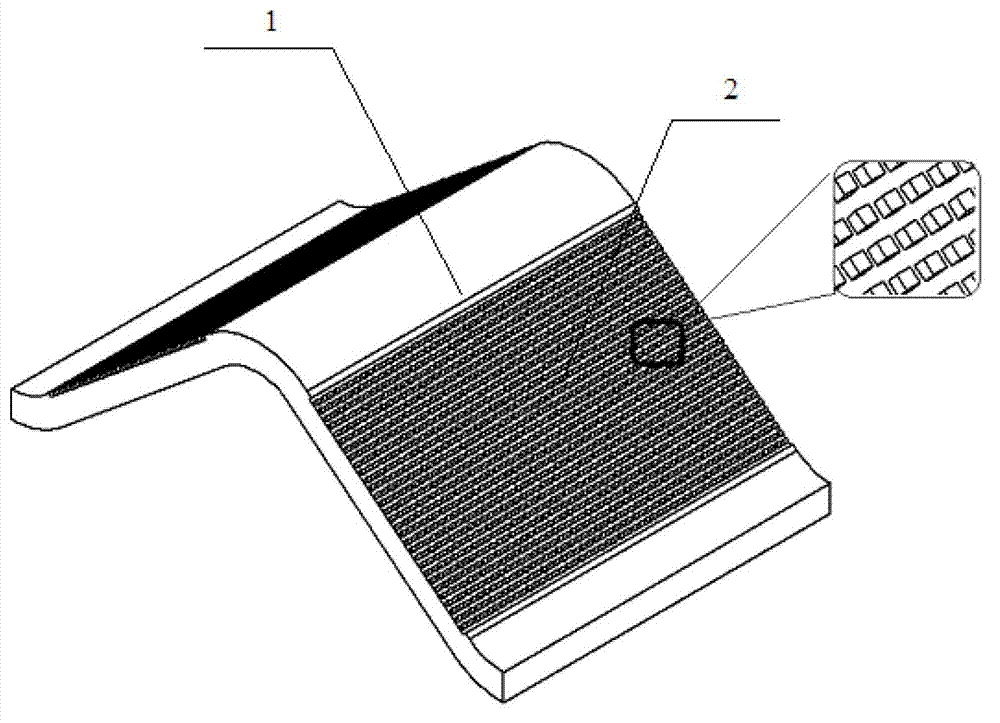

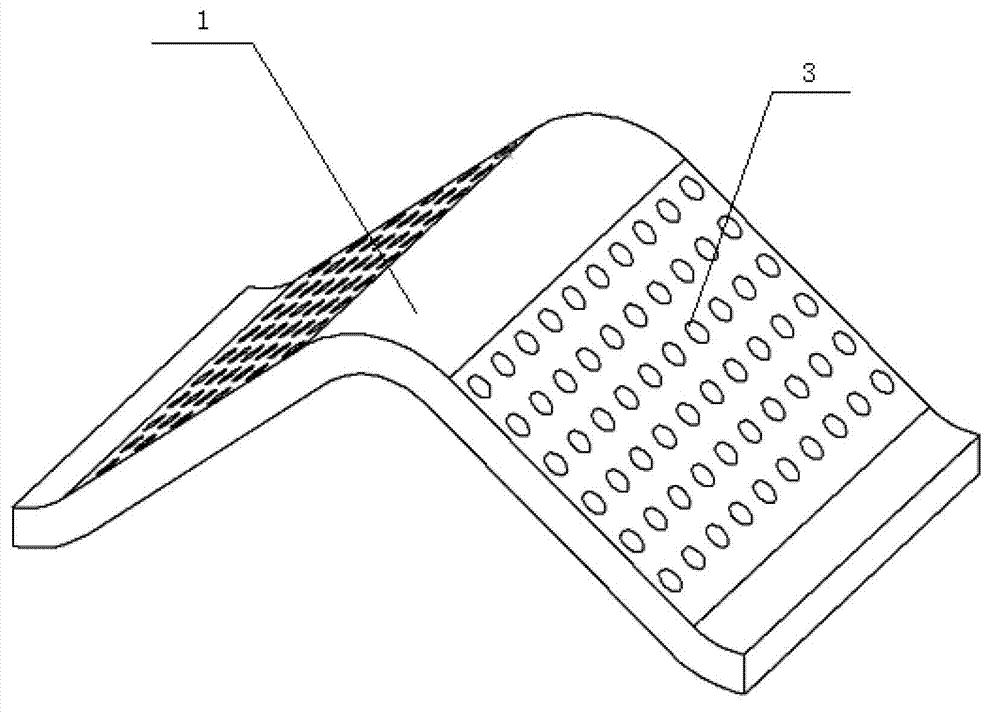

[0016] As shown in Figure 1, 2 or 3, the technical solution for the specific implementation of the present invention is: a heat exchange plate for a plate evaporator, based on the heat exchange plate base 1, the upper end surface of the heat exchange plate base 1 is processed The micro-ribs 2 are provided with dimples 3 or a rough structure is processed on the upper end surface of the heat exchange plate substrate.

[0017] The micro-ribs 2 processed on the upper end surface of the heat exchange plate base 1 are uniformly distributed, the height of the micro-ribs 2 is 0.02-0.05 mm, the length is 0.1-0.5 mm, and the width is 0.1-0.5 mm The distance bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com