Cold-region used multi-connected heat pump system and control method thereof

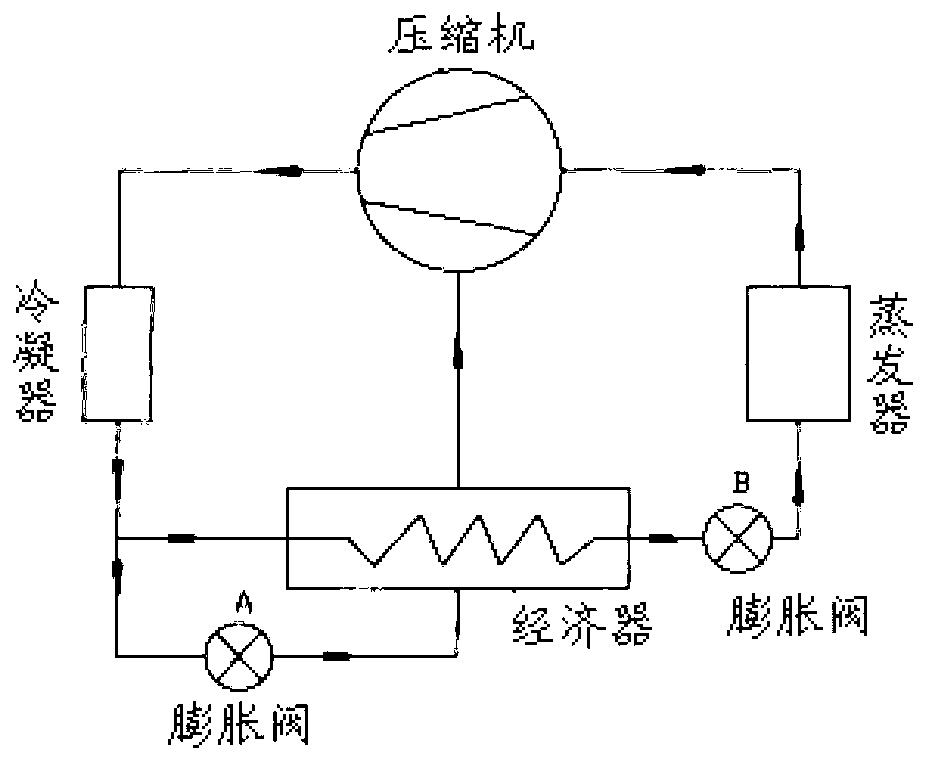

A heat pump system and technology in cold regions, applied in the multi-connected heat pump system and its control field using the technology of supplementing air to increase enthalpy, it can solve the problems of large flow pressure loss, large subcooling degree, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

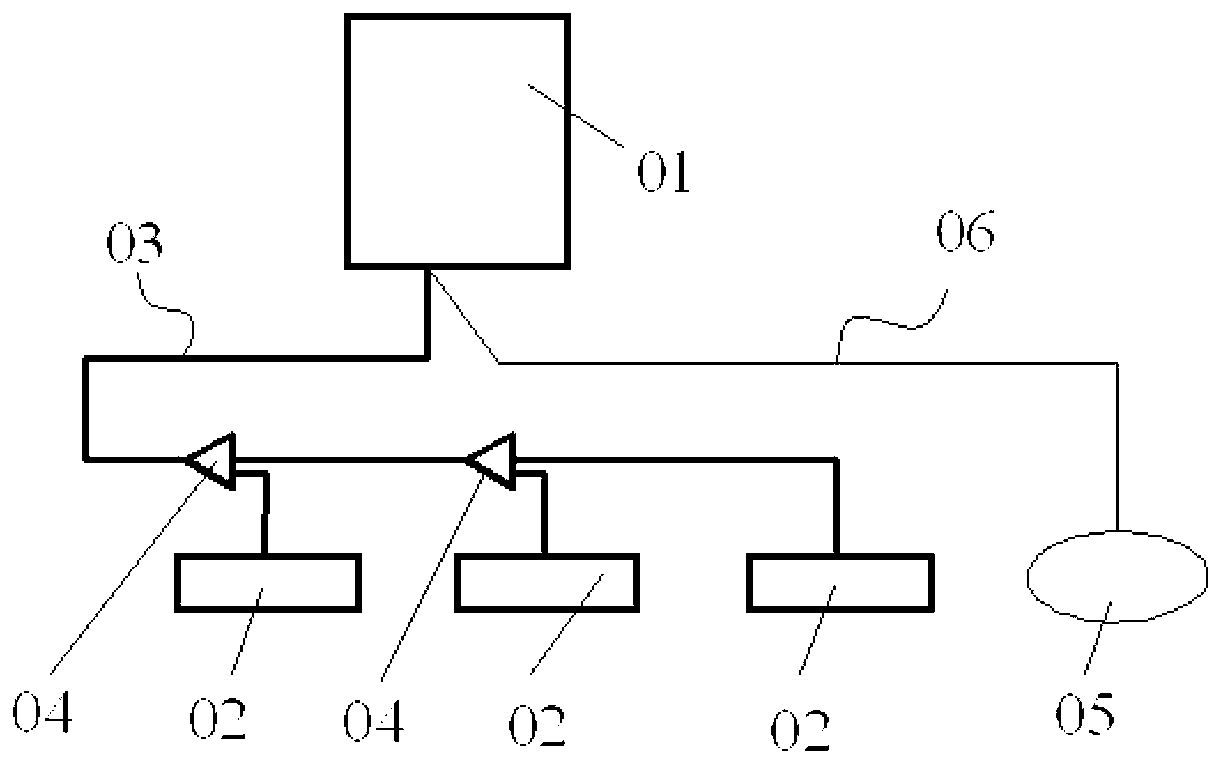

[0070] figure 2 A simplified structure diagram of the multi-connected heat pump system in the present invention is shown. Such as figure 2 As shown, it includes one or more outdoor units 01, one or more indoor units 02, refrigerant pipeline 03, branch pipe 04, control unit 05 and communication line 06. A plurality of outdoor units 01 form an outdoor unit, and the control unit 05 controls the outdoor unit through a communication line 06 . The outdoor unit 01 is connected to the indoor unit 02 through a refrigerant pipeline 03 and a branch pipe 04 .

[0071] In this embodiment, the multi-connected heat pump system includes one outdoor unit 01 and two indoor units 02 . Certainly, the numbers of outdoor units 01 and indoor units 02 of the multi-connected heat pump system in this embodiment are only exemplary, and the specific numbers of outdoor units 01 and indoor units 02 are determined according to the actual needs of users.

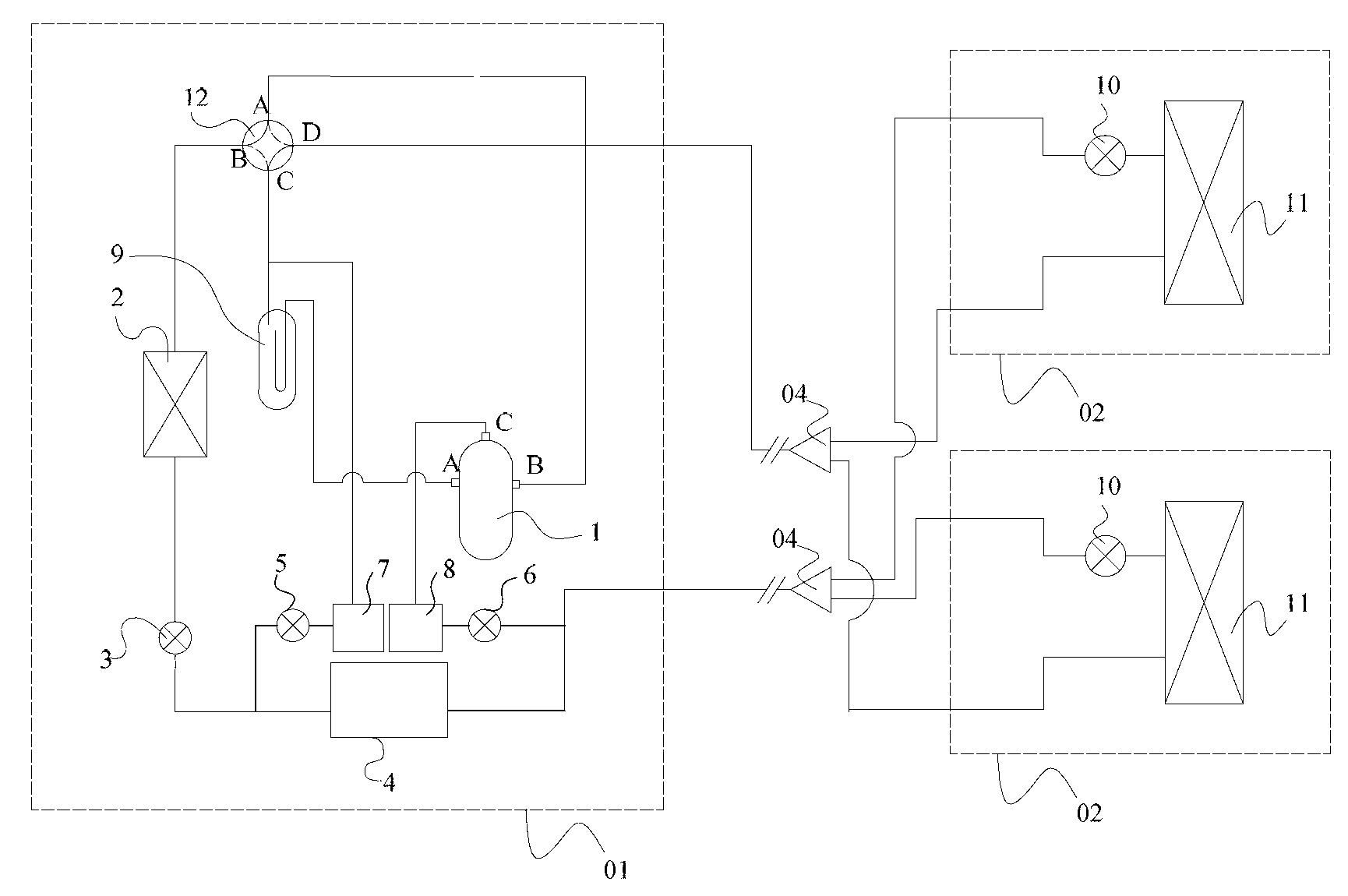

[0072] The working principle of the present in...

Embodiment 2

[0133] The structure of the multi-connected heat pump system in Embodiment 2 is similar to that of the multi-connected heat pump system in Embodiment 1. The difference is that in the outdoor unit, the first refrigerant branch circuit and the second refrigerant branch circuit share a heat exchanger, that is, the fourth heat exchanger 7.

[0134] For the convenience of description, the specific structure of one outdoor unit and one indoor unit is still used to illustrate the working principle of the multi-connected heat pump system in this embodiment.

[0135] Figure 7 A schematic structural diagram of the multi-connected heat pump system in Embodiment 2 is shown. Such as Figure 7 As shown, the outdoor unit of the multi-connected heat pump system is equipped with a compressor 1, a first heat exchanger 2, a first electronic expansion valve 3, a third heat exchanger 4, a second electronic expansion valve 5, and a third electronic expansion valve 6. The fourth heat exchanger 7...

Embodiment 3

[0147] The multi-connected heat pump system in Embodiment 3 is similar in structure to the multi-connected heat pump system in Embodiment 2, the difference is that the heat exchanger in the main refrigerant circuit is shared with the first refrigerant branch circuit and the second refrigerant branch circuit The heat exchanger is integrated as a sixth heat exchanger 32 . The third heat exchanger 4 in the main refrigerant circuit and the fourth heat exchanger 7 shared by the first refrigerant branch circuit and the second refrigerant branch circuit are two parts of the sixth heat exchanger 32 . Figure 8 A schematic structural diagram of the multi-connected heat pump system in Embodiment 3 is shown. Such as Figure 8 As shown, the main refrigerant circuit runs through one heat exchange channel in the sixth heat exchanger 32 , and the first refrigerant branch circuit and the second refrigerant branch circuit run through another heat exchange channel in the sixth heat exchanger 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com