Dual-fuel nozzle used for chemical regenerative cycle

A chemical reheating cycle and dual-fuel technology, applied in combustion chambers, combustion methods, combustion equipment, etc., can solve the problems of difficult organization of flow field, influence of gas turbine operation, flame elongation, etc., achieve uniform distribution of components, improve Combustion efficiency, flameout avoidance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention is described in more detail below in conjunction with accompanying drawing example:

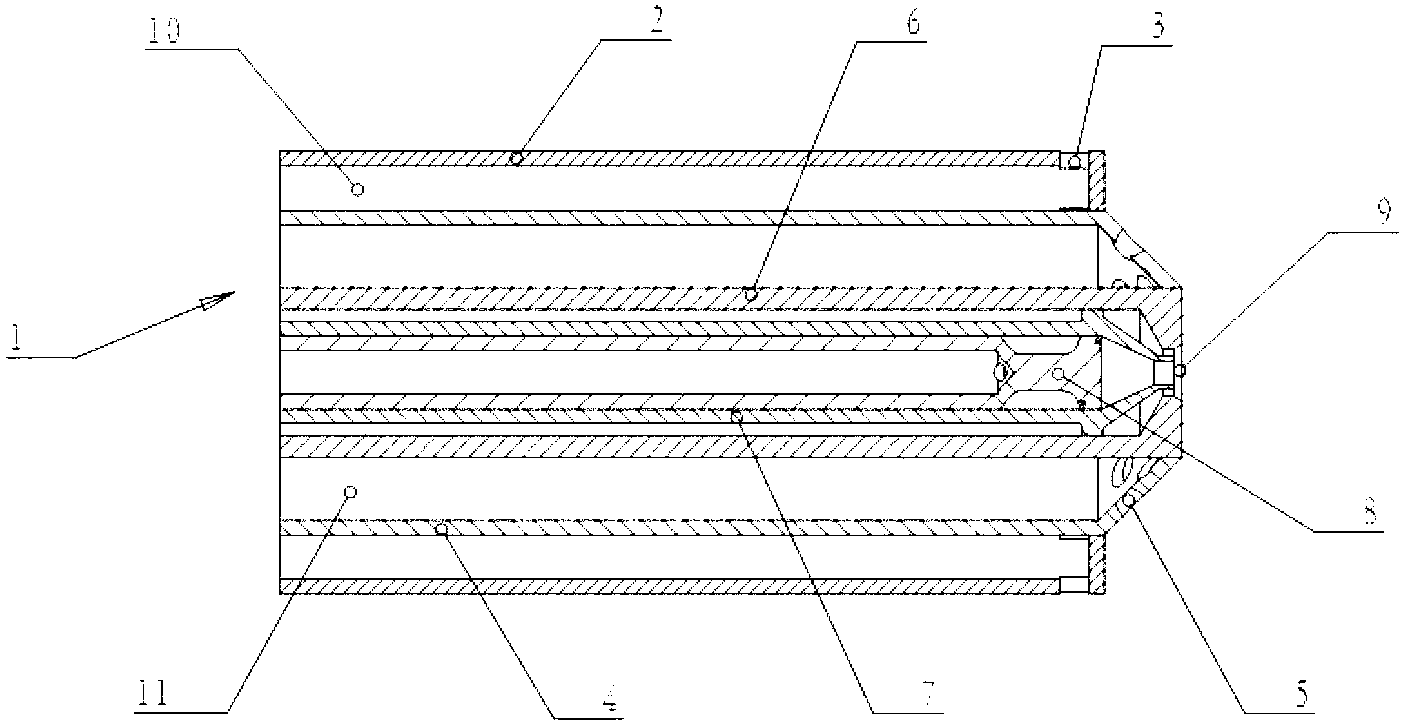

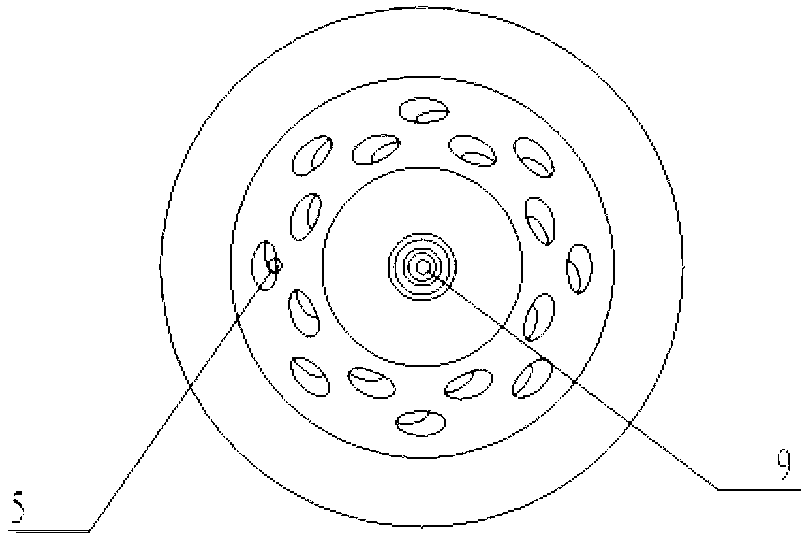

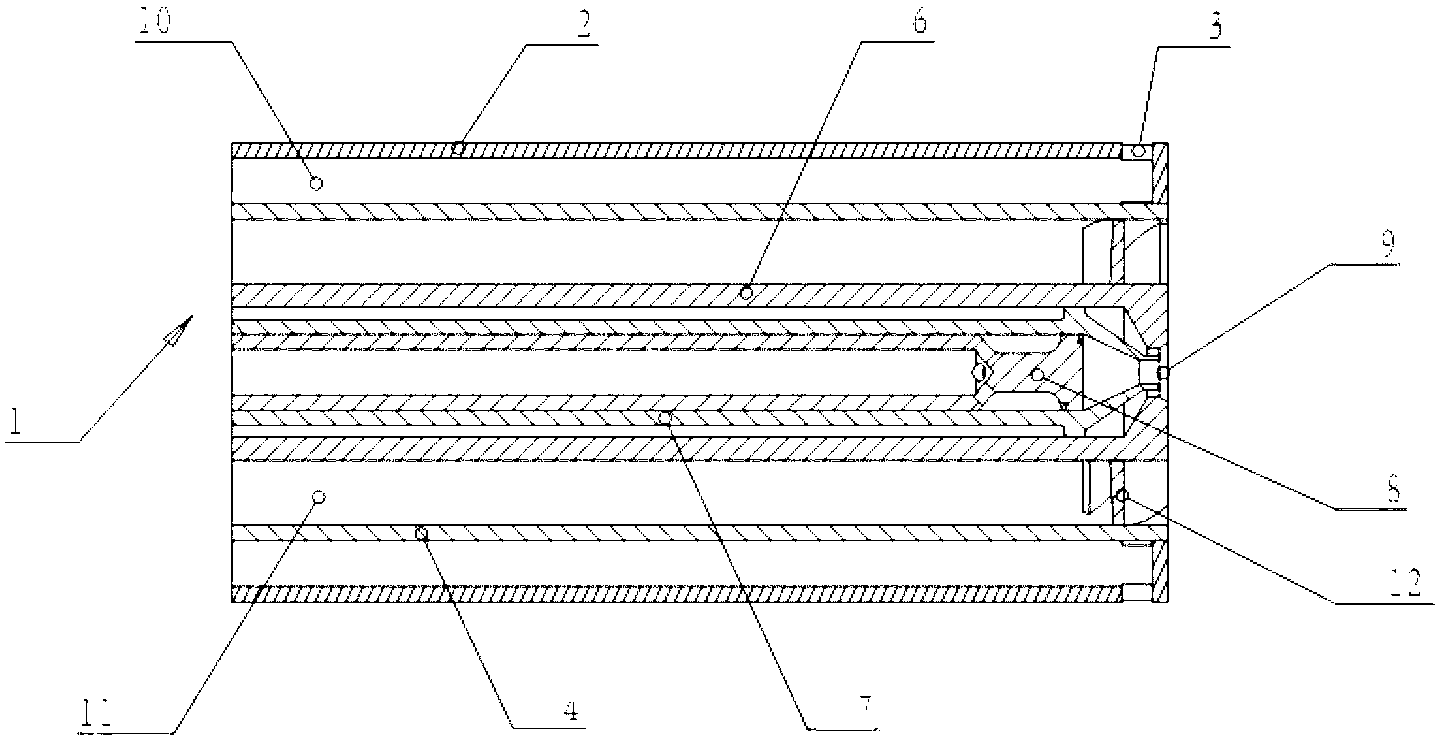

[0019] combine figure 1 ~6, the dual-fuel nozzle 1 designed by the present invention mainly includes a gas fuel passage 11, a gas fuel passage outer wall 4, an oblique air hole 5 or a gas fuel nozzle of the swirl plate 12 type, a water vapor passage 10, a water vapor passage outer wall 2, a water vapor passage Steam nozzle 3, main oil pipeline 6, auxiliary oil pipeline 7, auxiliary oil cyclone 8, oil nozzle 9, the oil pipeline is installed in the middle of the gas fuel channel 11, and the water vapor channel 10 is located in the gas fuel channel 11 The water vapor is ejected through the water vapor nozzle 3 located on the side of the wall of the water vapor channel 10, the gas fuel is ejected through the gas fuel nozzle formed by the inclined gas hole 5 or the swirl plate 12, and the liquid fuel is ejected through the nozzle of the main and auxiliary oil passages....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com