N-shaped steel rail connector

A technology of interface and rail, which is applied in the field of railway construction, can solve problems such as huge investment, loss, and impact on the living environment of passengers and people along the railway, and achieve the effect of improving transportation quality and operating speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

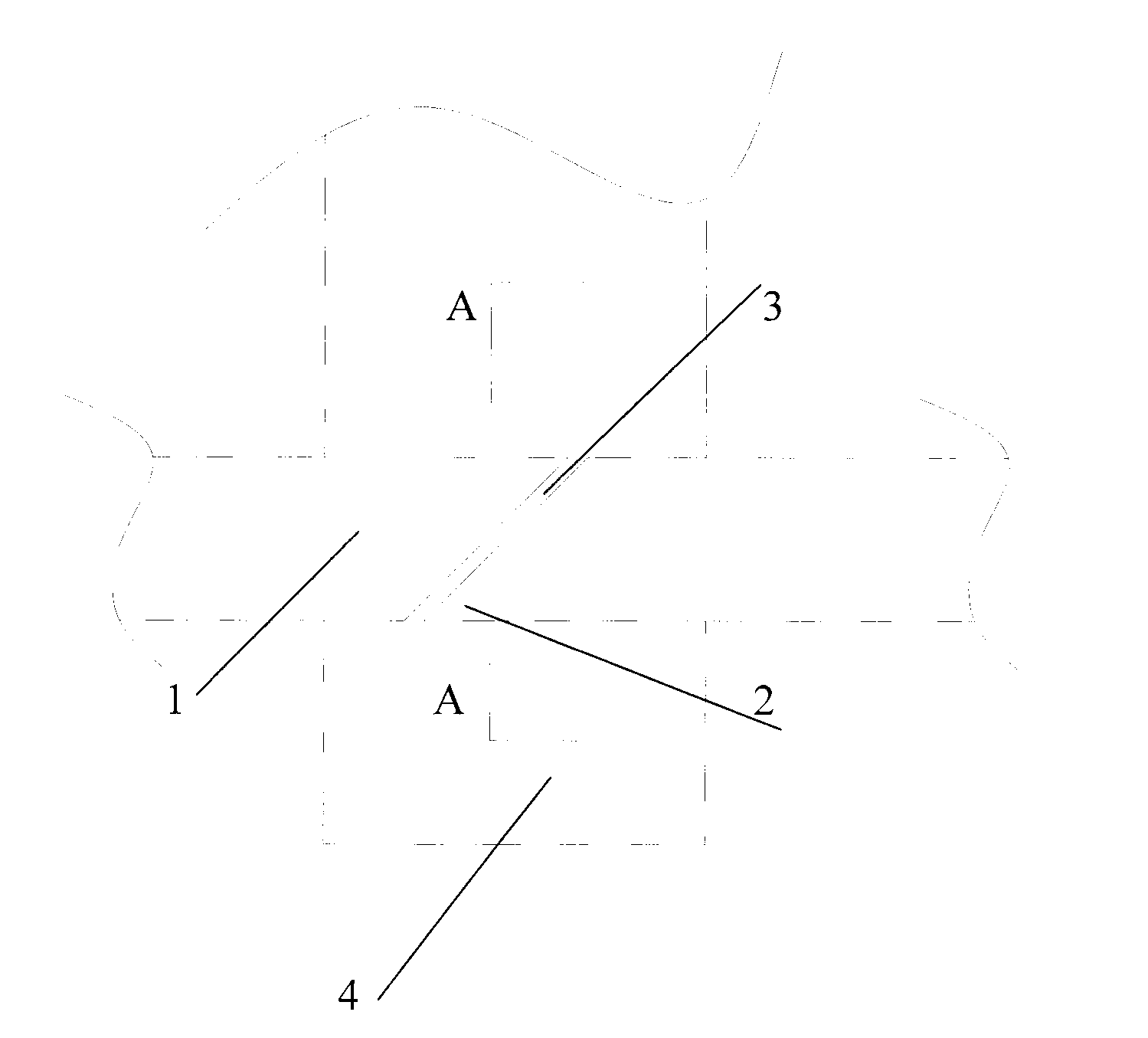

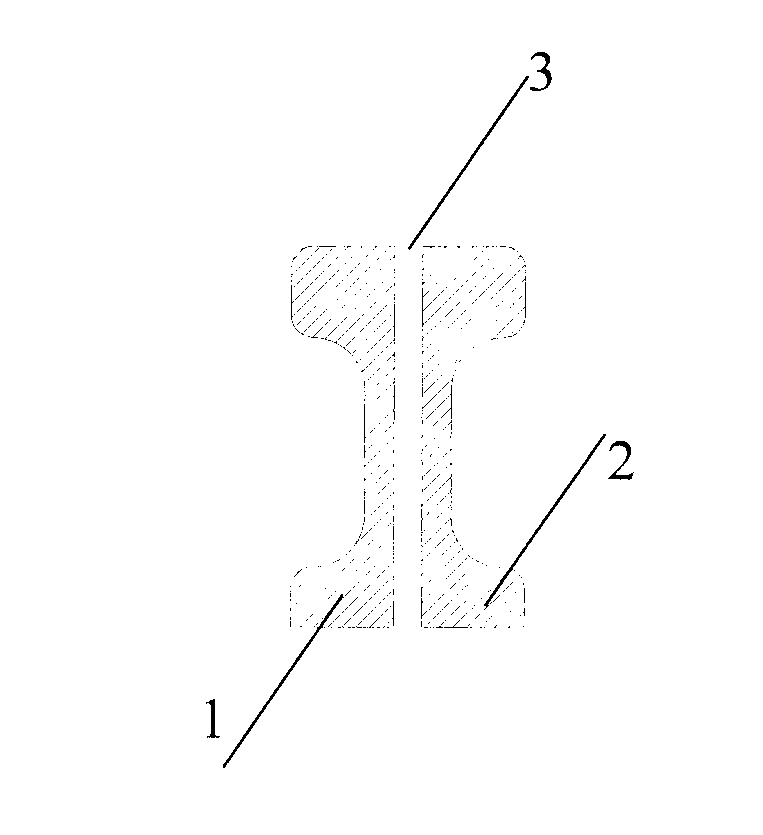

[0019] As shown in the figure: an N-shaped rail interface, the ends of two butted rails 1 have a corresponding bevel 2, and an expansion joint 3 is reserved between the two bevels 2, and the angle of the bevel 2 is ≥ 45°. The larger the angle is, the longer the connecting surface is, which is generally set to an angle of ≥45°. The lower part of the interface is provided with sleepers 4, and the left and right sides of the interface are provided with rail fastening splints.

[0020] The N-type rail interface is composed of two complementary triangles. The wheel rolls in this area and is pressed on the two rails at the same time, which is a harmonious and smooth transition, so there is no impact, no vibration, and no noise. This N-type rail interface can not only be used for Modern railway construction can also be used for track connections such as mine track transportation, factory driving and port gantry cranes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com