Polyethylenimine-aliphatic polyester graft polymer as well as preparation method and nanometer particle thereof

A polyethyleneimine and aliphatic polyester technology, which can be used in pharmaceutical formulations, medical preparations with inactive ingredients, powder delivery, etc., can solve problems such as easy light-induced fading, improve biological activity, wide application prospects, Toxicity reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

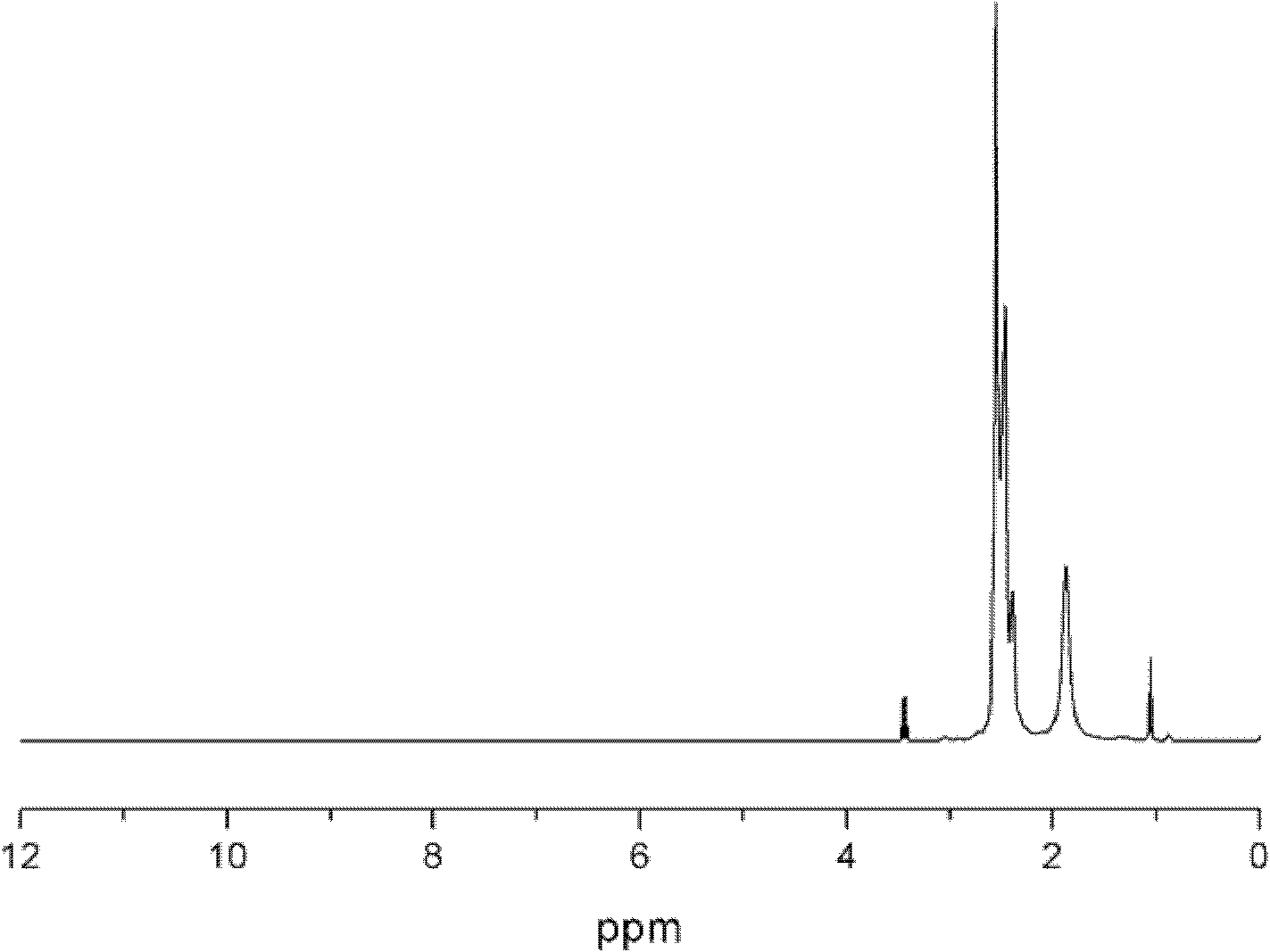

Image

Examples

Embodiment 1

[0064] This embodiment is used to illustrate the synthesis of polyethyleneimine-polylactic acid graft polymer of the present invention:

[0065] (1) 0.1mmol of dried polyethyleneimine (purchased from Sigma-Aldrich, with a weight average molecular weight of 25,000) having a structure shown in formula (5) was mixed uniformly with 150mL dimethyl sulfoxide to obtain a mixture, and The mixture was uniformly mixed with 0.15 mol lactide (purchased from Alfar Aesar, with a purity of 97%, analytically pure), and dissolved for 1 h under nitrogen protection. Add 8 mL of triethylamine, and react at 85° C. for 15 h under the protection of nitrogen to obtain a mixture containing a reaction product of polyethyleneimine-polylactic acid grafted polymer. The dimethyl sulfoxide in the reaction product of this mixture was removed, and the reaction product after removing dimethyl sulfoxide was precipitated in 500mL water to obtain a solid product; Dry it in the oven for 48 hours, then extract it ...

Embodiment 2

[0070] This embodiment is used to illustrate the synthesis of polyethyleneimine-polyglycolide graft polymer of the present invention:

[0071] (1) 5mmol of dried polyethylenimine (purchased from Sigma-Aldrich company, with a weight average molecular weight of 600) having a structure shown in formula (5) is mixed with 150mL tetrahydrofuran to obtain a mixture, and the mixture is mixed with 75mmol Glycolide (purchased from Alfar Aesar, with a purity of 97%, analytically pure) was mixed uniformly and dissolved for 1 h under nitrogen protection. Add 1.5 mL of ethanolamine, and react at 70° C. for 10 h under the protection of nitrogen to obtain a mixture containing a reaction product of polyethyleneimine-polyglycolide graft polymer. The tetrahydrofuran in the mixture was removed, and the reaction product after the removal of tetrahydrofuran was precipitated in 500mL of water to obtain a solid product; the solid product was washed with water three times in turn, dried in a vacuum ov...

Embodiment 3

[0076] This embodiment is used to illustrate the synthesis of polyethyleneimine-polycaprolactone graft polymer of the present invention:

[0077] (1) 500 μmol of dried polyethyleneimine (purchased from Sigma-Aldrich, with a weight-average molecular weight of 15,000) having a structure shown in formula (5) is mixed with 150 mL N, N-dimethylformamide to obtain a mixture , and the mixture was uniformly mixed with 0.5 mol caprolactone (purchased from AlfarAesar Company, with a purity of 97%, analytically pure), and dissolved for 1 h under nitrogen protection. Add 5 mL of diethanolamine, and react at 80° C. for 12 h under the protection of nitrogen to obtain a mixture containing a reaction product of polyethyleneimine-polycaprolactone grafted polymer. N,N-dimethylformamide in the mixture was removed, and the reaction product after removing N,N-dimethylformamide was precipitated in 500mL of water to obtain a solid product; the solid product was washed with water three times successi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com