Tire bead transfer ring and transferring method of tire bead transfer ring

A transfer ring and bead technology, applied to tires, other household appliances, household appliances, etc., can solve problems such as bead deformation, avoid bead slippage, solve elastic contact problems, and overall flatness and verticality Guaranteed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

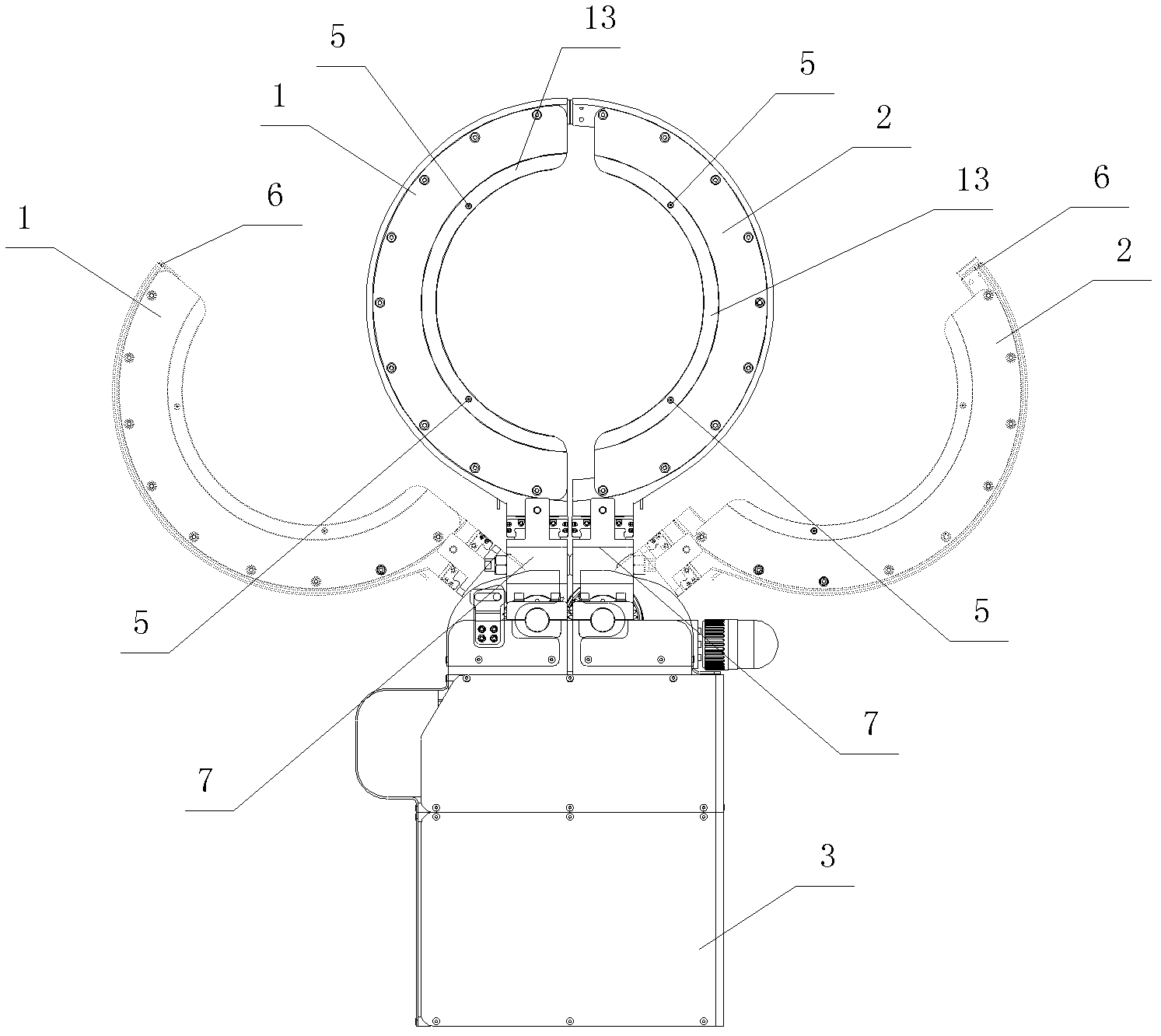

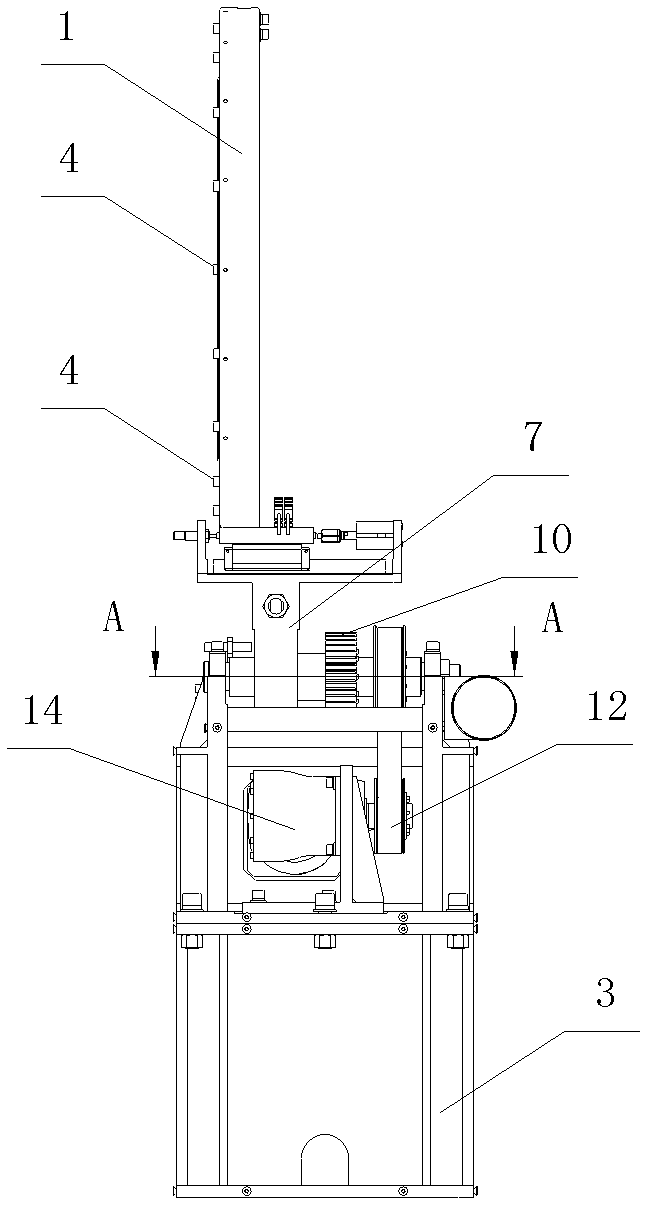

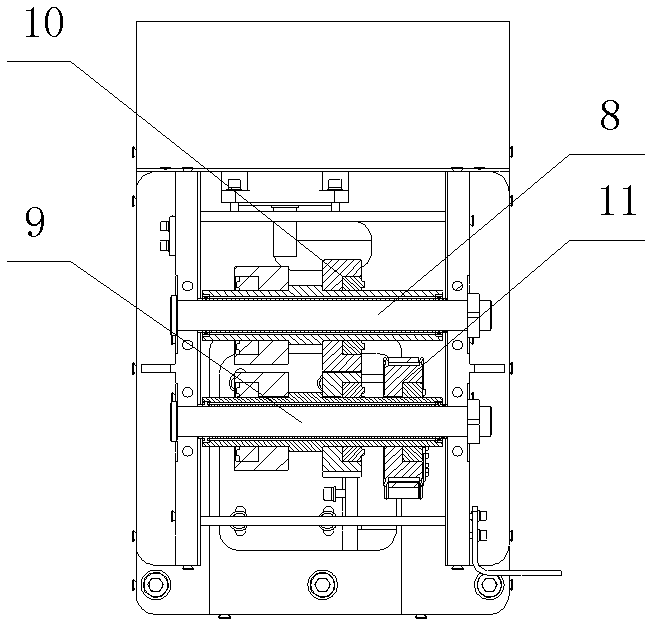

[0039] Example 1, such as Figure 1 to Figure 3 As shown, the bead transfer ring mainly includes a pair of left half-ring 1 and right half-ring 2 that are separated and closed.

[0040] At the butt end of the left half ring 1 and the right half ring 2, there is a pair of positioning blocks 6 that are butted and occluded with each other. Relying on the precise docking between the positioning blocks 6, the left half ring 1 and the right half ring 2 can maintain the entire ring body after being closed. Better vertical flatness is beneficial to improve the bead positioning accuracy.

[0041] The left half-ring 1 and the right half-ring 2 are respectively installed on the mounting seat 3 which is arranged vertically above and realizes reciprocating sliding through the top slide rail.

[0042] Along the inner diameters of the left half-ring 1 and the right half-ring 2, semi-annular bosses 13 are arranged respectively, and several magnets 4 for magnetically absorbing the bead are in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com