Ceramic bond gross blow hole repairing grinding wheel and manufacturing method thereof

A ceramic bond, large pores technology, used in ceramic products, grinding/polishing equipment, abrasives, etc., can solve the problem of inability to enter the actual grinding, to avoid weak bonding, improve hardness, and ensure safety performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

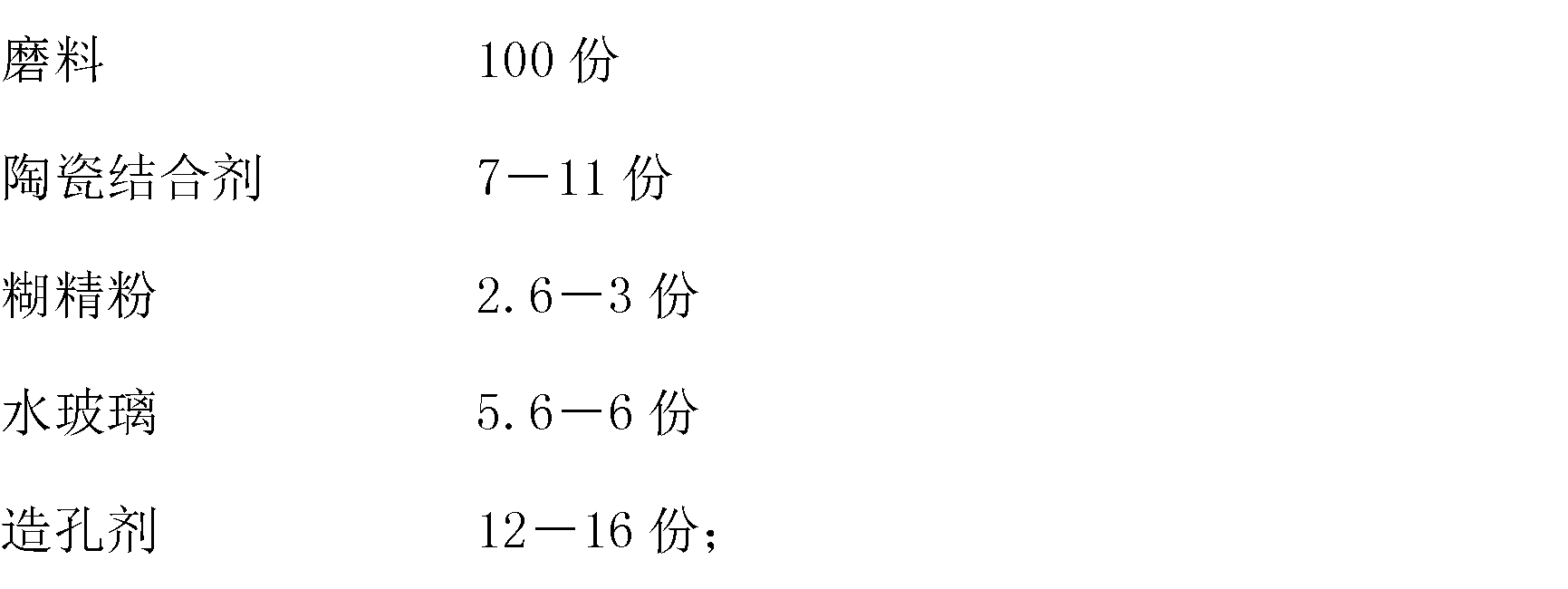

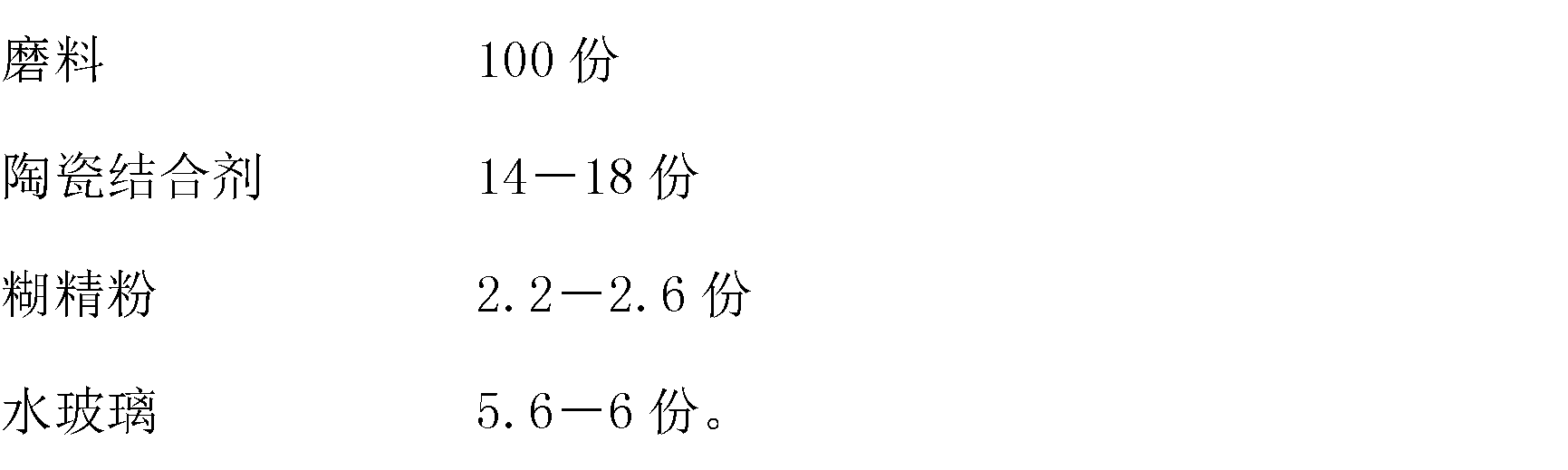

[0022] A method for preparing a vitrified large-pore grinding wheel, the preparation steps are as follows: (1) First prepare a vitrified bond, put 18 parts of clay powder, 63 parts of feldspar powder and 14 parts of boron glass powder in a ceramic pot In the ball mill, add Φ10-15mm ceramic balls accounting for 15% of the mass of the mixture, and then perform ball milling at a speed of 960r / min for 4 hours, and pack the material into bags for later use; Pretreatment: Put the walnut shell particles into the countercurrent mixer, then add liquid phenolic resin PF2127, the mass ratio of walnut shell particles and liquid phenolic resin PF2127 is 100:15, then stir for 5 minutes to mix well, until the walnut shell particles are completely wetted Evenly placed in a metal container, dried at 80°C for 20 minutes, then passed through a 12-mesh sieve, and finally hardened in an oven at 180°C for 20 minutes, and sealed for later use after cooling; (3) Processing process: core: 100 parts of ...

Embodiment 2

[0024] A method for preparing a vitrified large-pore grinding wheel, the preparation steps are as follows: (1) First prepare a vitrified bond, put 20 parts of clay powder, 65 parts of feldspar powder and 15 parts of boron glass powder in a ceramic pot In the ball mill, add Φ10-15mm ceramic balls accounting for 18% of the mass of the mixture, and then perform ball milling at a speed of 960r / min for 5 hours, and pack the material into bags for later use; Pretreatment: Put the walnut shell particles into the countercurrent mixer, then add liquid phenolic resin PF2127, the mass ratio of walnut shell particles and liquid phenolic resin PF2127 is 100:18, then stir for 8 minutes to mix well, until the walnut shell particles are completely wetted Evenly placed in a metal container, dried at 90°C for 25 minutes, then passed through a 12-mesh sieve, and finally hardened in an oven at 180°C for 25 minutes, and sealed for later use after cooling; (3) Processing process: core: 100 parts of ...

Embodiment 3

[0026]A method for preparing a vitrified large-pore grinding wheel, the preparation steps are as follows: (1) First prepare a vitrified bond, put 22 parts of clay powder, 67 parts of feldspar powder and 16 parts of boron glass powder in a ceramic pot In the ball mill, add Φ10-15mm ceramic balls accounting for 20% of the mass of the mixture, and then perform ball milling at a speed of 960r / min for 6 hours, and pack the material into bags for use; Pretreatment: Put the walnut shell particles into the countercurrent mixer, then add liquid phenolic resin PF2127, the mass ratio of walnut shell particles and liquid phenolic resin PF2127 is 100:20, then stir for 10 minutes to mix well, until the walnut shell particles are completely wetted Evenly placed in a metal container, dried at 100°C for 30 minutes, then passed through a 12-mesh sieve, and finally hardened in an oven at 180°C for 30 minutes, and sealed for later use after cooling; (3) Processing process: core: 100 parts of parti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com