A method for preparing δ-type cemented carbide micro milling cutter

A technology of cemented carbide and micro milling cutters, which is applied in the manufacture of tools, metal processing equipment, electrochemical processing equipment, etc., can solve the problems of low processing efficiency, material overcut, and the limitation of the minimum diameter of the tool, so as to improve processing efficiency, The effect of accelerating discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

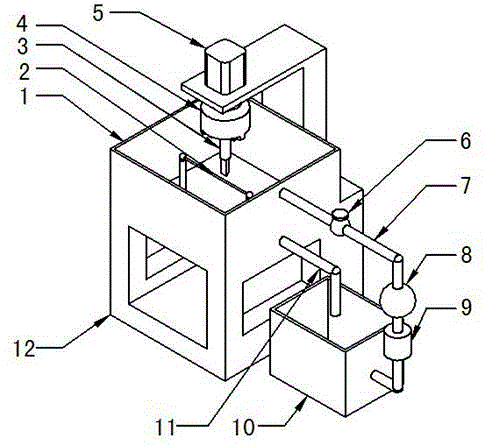

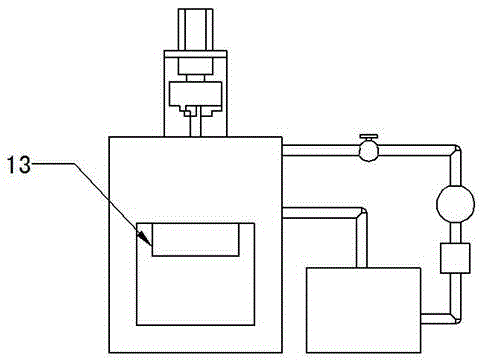

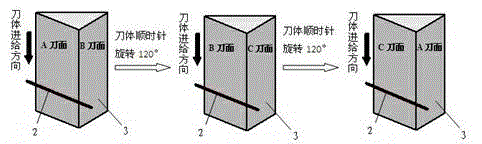

[0024] Such as figure 1 and 2 The device for preparing Δ-type cemented carbide micro-milling cutters combined with ultrasonic-assisted micro-electrolysis includes: electrolyte tank 1, which provides a processing environment for micro-electrolysis; tool electrode wire 2, which is fixed by a positioning fixture, and used for preparation after power-on Δ-type cemented carbide micro milling cutter 3; tool holder 4, used to move and clamp Δ-type carbide micro-milling cutter, and make the milling cutter reach the processing position through control; motor 5, provide power for the rotation of the tool holder; valve 6 , to control the circulation of the electrolyte between the electrolyte storage tank and the electrolyte tank, and stop the flow when it is closed; the electrolyte tank inlet pipe 7 makes the electrolyte flow into the electrolyte tank; the pressure pump 8 provides power to make the electrolysis The liquid flows into the electrolyte tank from the electrolyte storage tank...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com