Device and method for cleaning and drying wafer cassettes

A wafer box and drying technology, which is applied in the direction of liquid cleaning method, drying gas arrangement, chemical instruments and methods, etc., can solve the problems that affect the normal use of the wafer box, poor drying effect, and unstable drying effect. Achieve the effect of improving stability and safety, improving drying effect and avoiding reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

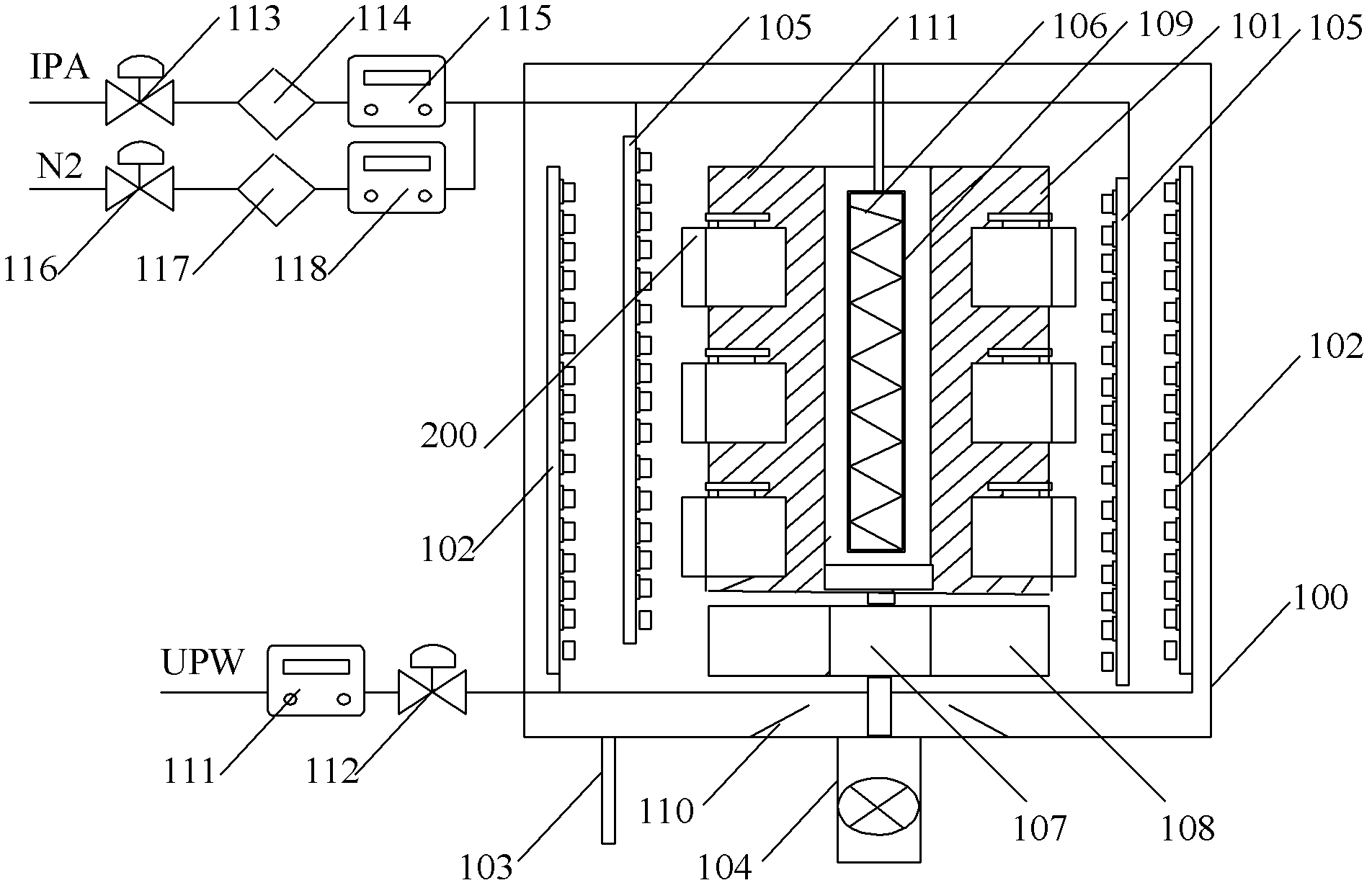

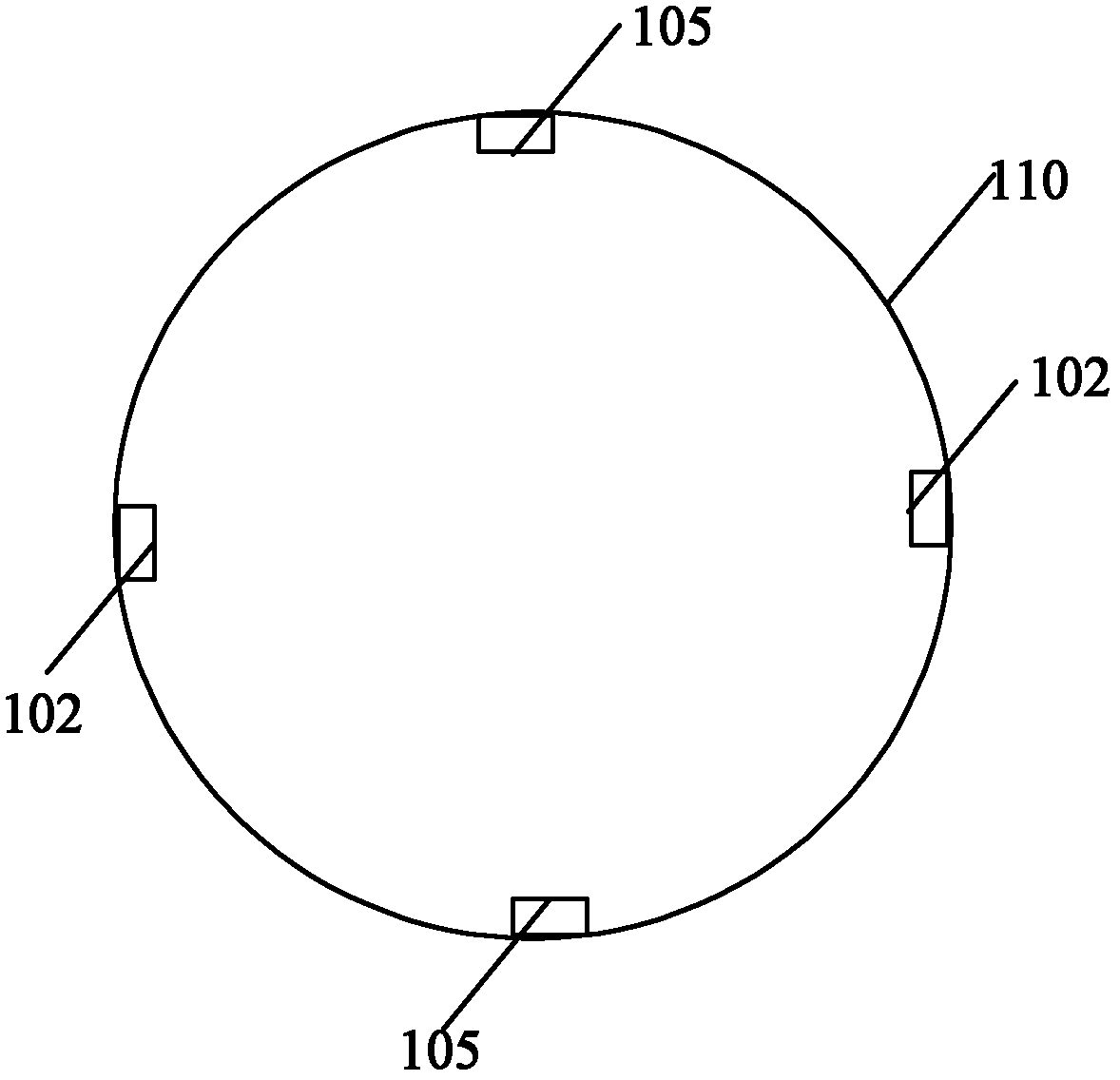

[0037] see figure 1 , this device for cleaning and drying wafer cassettes includes a cleaning chamber 100, a support 101 for supporting several wafer cassettes 200, a cleaning liquid nozzle 102 connected to an external cleaning liquid source, a liquid discharge pipeline 103 and an exhaust gas The pipeline 104, the drain pipeline 103 and the exhaust pipeline 104 are respectively connected to the bottom of the cleaning chamber 100, the bracket 101 and the cleaning liquid nozzle 102 are arranged in the cleaning chamber 100, so The above-mentioned device for cleaning and drying the wafer cassette also includes a drying gas nozzle 105 externally connected to a drying gas source, and the drying gas nozzle 105 is arranged in the cleaning chamber 100 . In addition to the cleaning liquid nozzle 102 connected to the cleaning liquid source in the cleaning chamber 100, the present invention also sets the drying gas nozzle 105 connected to the drying gas source. The use of dry gas can not ...

Embodiment 2

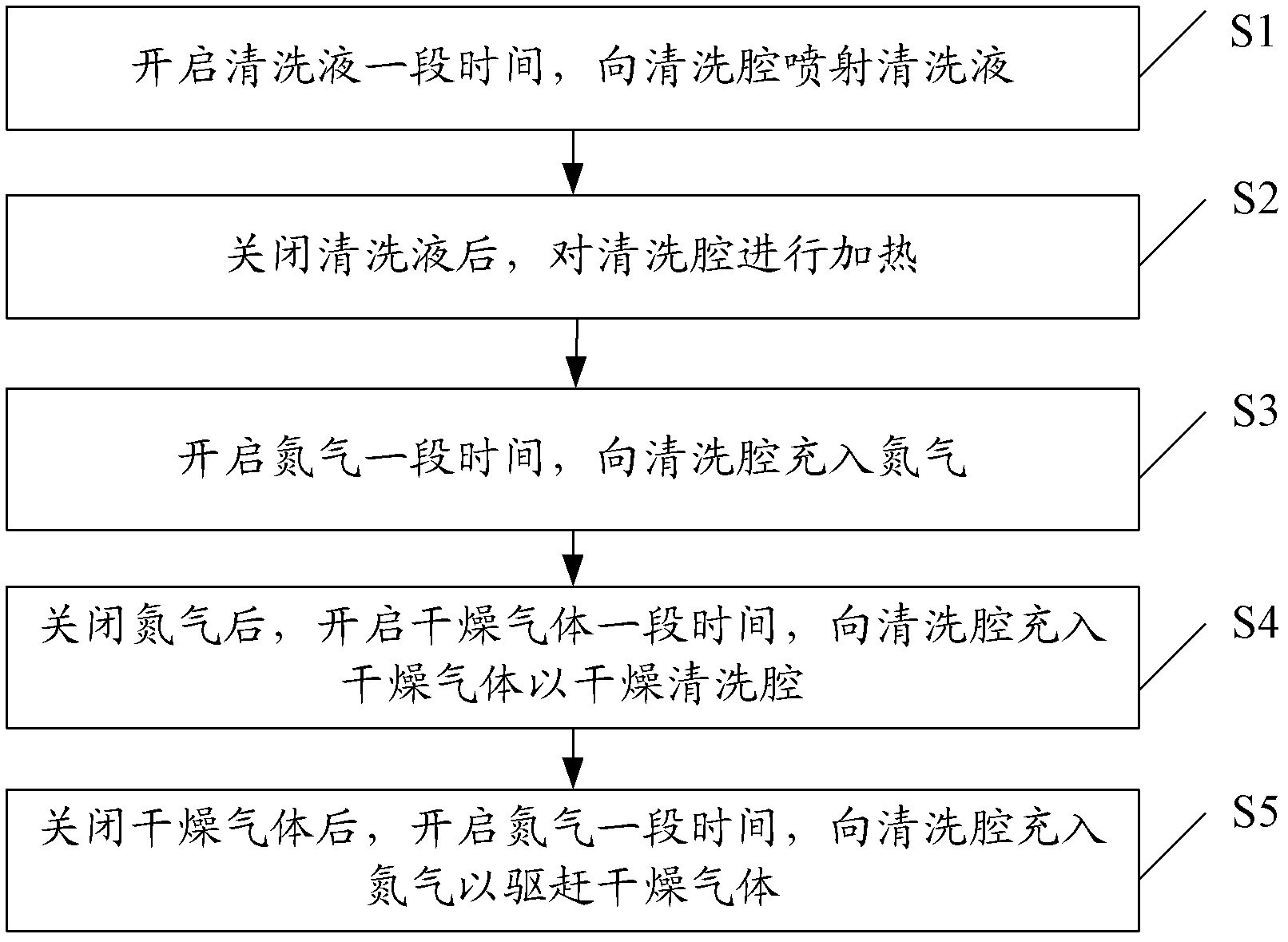

[0047] see image 3 , this method for cleaning and drying the wafer box, the wafer box is placed in the cleaning chamber, the device for cleaning and drying the wafer box as described in Embodiment 1 can be used, but it is not limited to this structure , the method includes the following steps:

[0048] Proceed to step S1, turn on the cleaning solution for a period of time, and spray the cleaning solution into the cleaning chamber to fully clean the wafer cassette. The time can be set according to actual conditions. In the step S1 of the present embodiment, the cleaning liquid adopts ultrapure water (UPW), and the time of opening the cleaning liquid is 10 minutes, and the flow rate of the cleaning liquid is 60 liters / minute (L / Min); It is in the closed state; the support and the wafer cassette on it are in the rotating state.

[0049] Carry out step S2, after closing the cleaning liquid, heat the cleaning chamber for a period of time to dry the cleaning chamber. This step S2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com