One-step shaping technology for coating epoxy powder on inner wall and outer wall of steel pipe

A powder coating, wall epoxy technology, applied in the coating, the device for coating liquid on the surface, the pretreatment surface, etc., can solve the problems of complex process and large floor space, and achieve compact layout and floor space. Small, high-efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings.

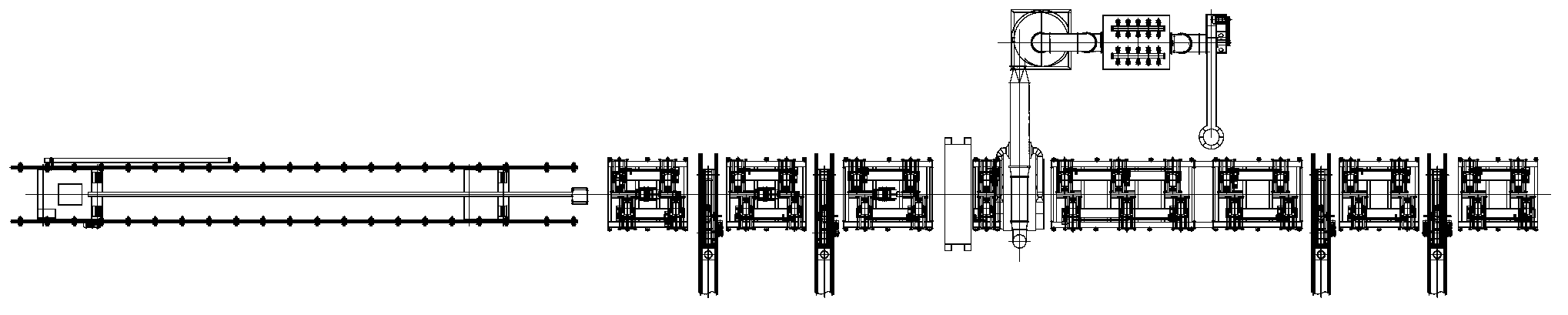

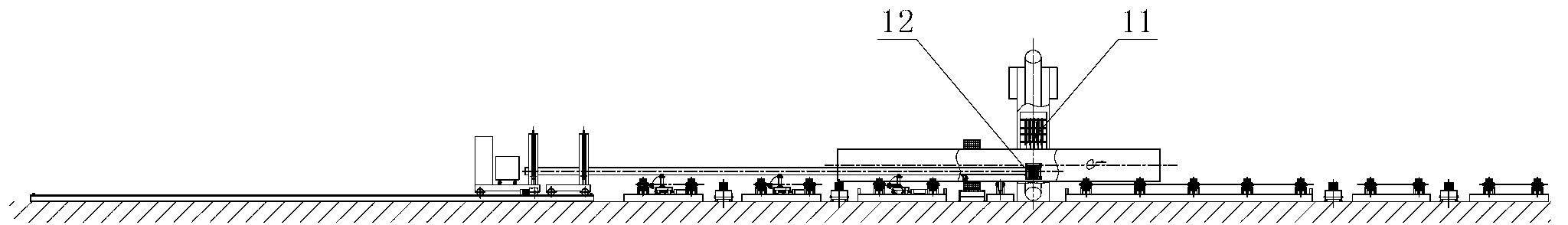

[0022] The inner and outer walls of the steel pipe are coated with epoxy powder in one molding process. The inner wall epoxy powder coating and the outer wall epoxy powder coating are carried out simultaneously on a production line, which includes the inner epoxy mobile spraying vehicle 1, the inner epoxy spraying rod 2, and the support rail Trolley 3, nozzle 4, spiral conveying roller table 5, pipe transport trolley 6, right-angle lifting support frame 7, steel pipe 8, intermediate frequency heating coil 9, outer epoxy powder spray booth 10, inner epoxy spray rod 2 and one end of the inner ring The oxygen mobile spraying vehicle 1 is fixedly connected, and the other end of the inner epoxy spraying rod 2 is provided with a spray head 4; the inner epoxy spraying rod 2 is supported by the inner epoxy mobile spraying vehicle 1 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com