Electric vehicle controller and vehicle including said electric vehicle controller

A technology for electric vehicles and controllers, which is applied to printed circuits connected to non-printed electrical components, circuit layout on support structures, cooling/ventilation/heating transformation, etc., and can solve the problem of power lines, three-phase output lines and signal Difficult to distinguish connection, difficult maintenance, desoldering and other problems, to achieve the effect of good normal working environment, convenient and fast external connection, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Below in conjunction with accompanying drawing, the present invention will be further described with specific embodiment, see figure 1 — Figure 15 :

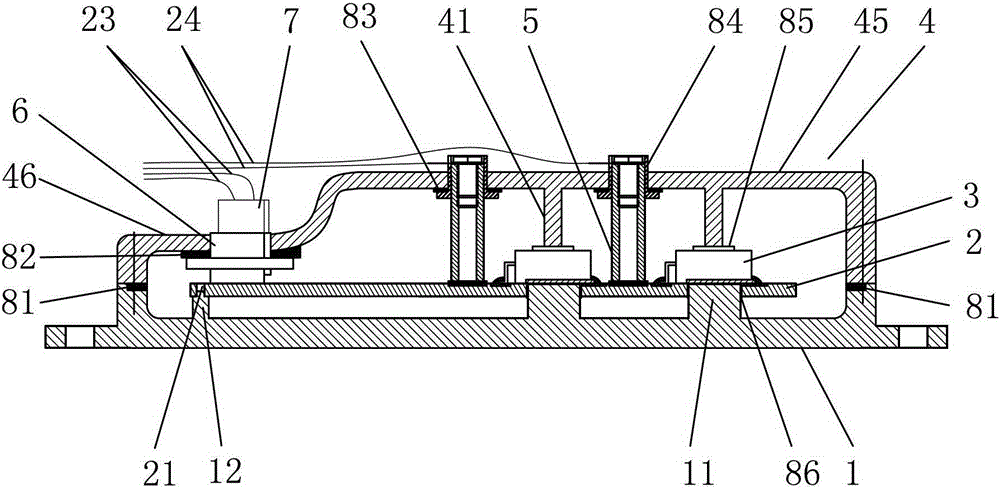

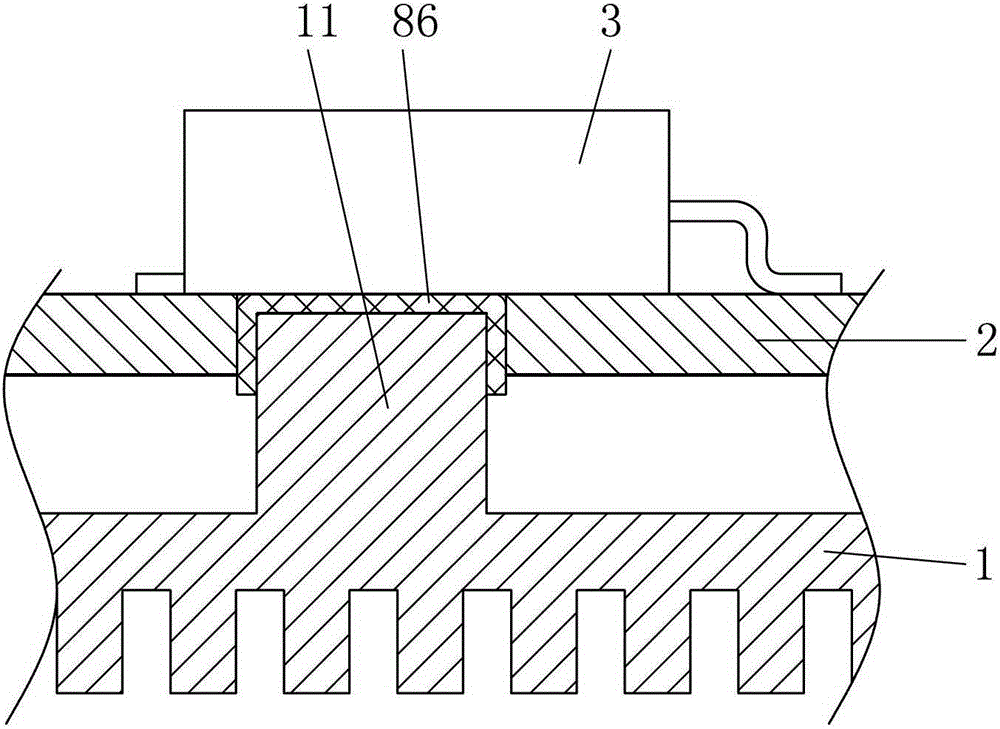

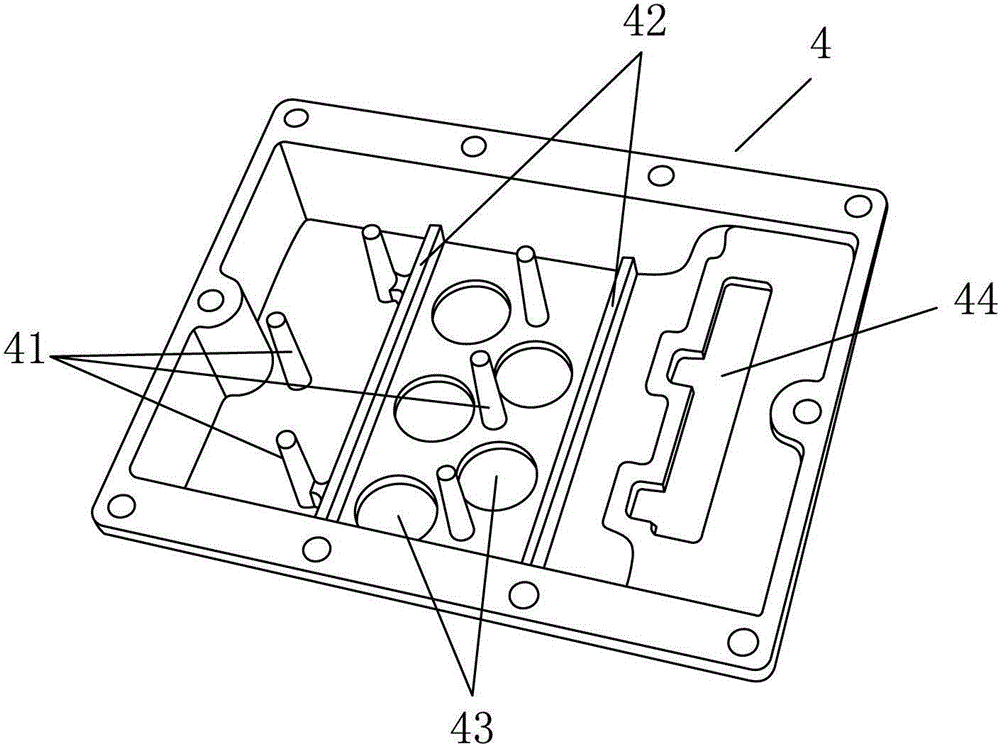

[0039] The electric vehicle controller includes a closed box body composed of a base 1 and an upper cover 4, and a circuit board 2 of the controller arranged in the box body, and a plurality of chip power devices 3 installed on the circuit board 2 are installed on the same position. Correspondingly, a through hole 22 penetrating the circuit board 2 is provided, and a SMD power device 3 is installed on each installation position of the circuit board 2, and several heat conduction columns 11 provided on the upper surface of the base 1 extend into each circuit board 2 respectively. In the through hole 22 of the corresponding chip power device 3 and insulated contact with the bottom plane 31 (actually: several heat conducting columns 11 provided on the upper surface of the base 1 extend into the through hole 22 of each circ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com