Wireless hollow inclusion strainmeter and method

A technology of hollow inclusions and strain gauges, which is applied to force/torque/work measuring instruments, measuring devices, instruments, etc., can solve problems such as the influence of measurement data reliability, the scrapping of hollow inclusion strain gauges, and inconvenient measurement work. Achieve the effects of improving the measurement success rate, saving measurement costs, and easy and fast installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

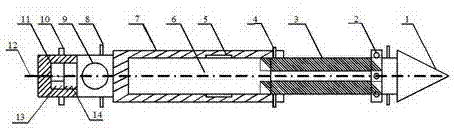

[0035] The wireless hollow inclusion strain gauge of the present invention includes three parts: a strain measuring part, a wireless transmitting part and a guiding part. The strain measuring part, the wireless transmitting part and the guiding part are connected with each other in a plug-in manner, which will be described respectively below.

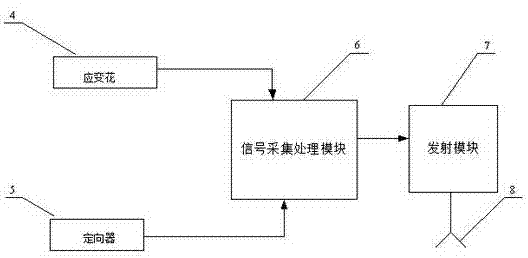

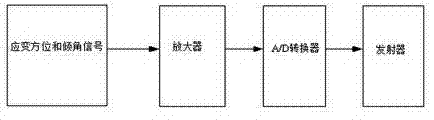

[0036] Such as figure 1 , figure 2 As shown, the measurement part is located in the middle, including 3 sets of strain rosettes (5) and 1 orientator (9) built on the wireless hollow inclusion strain gauge; the strain measurement is completed by 3 sets of resistance strain rosettes (5), and the orientation The device (9) measures the wireless hollow inclusion strain gauge and the drilling direction; the wireless transmitting part 1 includes a wireless transmitting module (11); ) for pre-processing an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com