A Displacement Spiral Design Method of Volute

A design method and spiral technology, applied to mechanical equipment, non-variable pumps, components of pumping devices for elastic fluids, etc., can solve problems such as flow chaos in the air outlet tube, and achieve improved flow conditions and high efficiency. The effect of increasing and reducing the volume of the volute

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings.

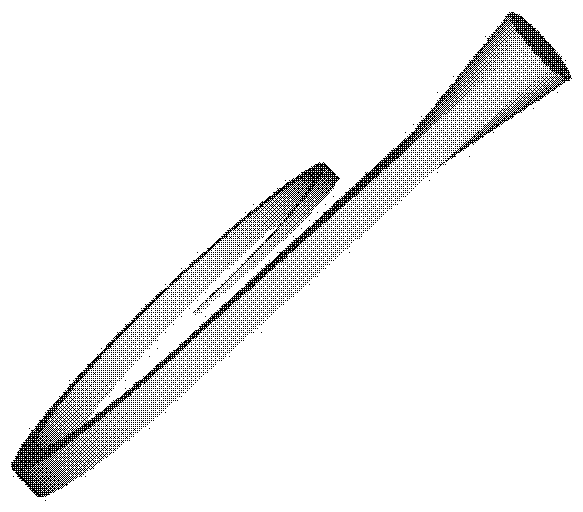

[0021] Such as Figure 1~3 As shown, the helix is used as the connection line of the centers of each section of the volute, and is expanded along the circumferential direction of the volute; the volute is divided into 8 to 12 section positions according to the circumferential direction, and then the centerline of each section is compared with the centerline of the previous section. Offset along the axis by 2 to 5 mm, and the connecting line of the centers of each section forms a helix, and then forms a structure of a transverse cochlear tongue.

[0022] The horizontal volute tongue is a method of offsetting the center line of the section of the volute. After avoiding the interference between the volute and the air outlet, the initial small section of the volute is preserved, that is, the small section of 0°~10° is cut off to guide Flow, improve efficiency,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com