Detection and sealing integrated method and device for gas extraction drill hole

A technology of gas drainage and coal body, which is applied in the direction of gas discharge, safety devices, mining equipment, etc., can solve problems such as lack of pertinence, high conveying pressure, and gas leakage in drilling holes, and achieve convenient operation, overcome powder waste, Effect of reducing delivery pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] An embodiment of the present invention will be further described below in conjunction with the accompanying drawings.

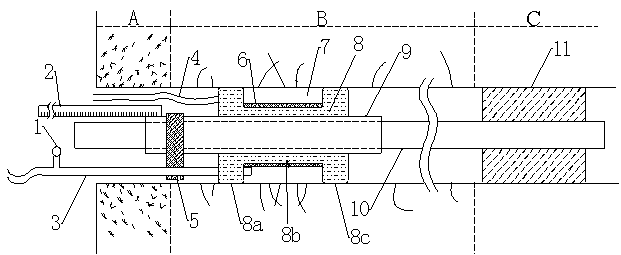

[0015] Due to the destructive effect on the coal body during the excavation of the roadway, a coal body crushing area A will be formed near the wall of the roadway. The coal body in this area is in a loose and broken state, and the crack length is small; There is a fissure area B behind the area A, and the length of the fissures in this area is long; the coal seam behind the fissure area B is subject to high pressure and the coal body is dense, so there are few fissures, which is the area C with sparse fissures. The fissures within the range of fissure area B are often separated by a certain distance, so it is necessary to detect the position of each fissure, and then block it in a targeted manner. Use the camera on the probe rod of the borehole detector to detect the wall of the borehole step by step from the hole inward. First, determine the range of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com