Anti-corrosion method for mechanical oil extraction shaft

An oil production well and machinery technology, applied in the field of oilfield development and oil production technology, can solve problems such as oilfield losses, threats to normal operation of oil pumps, and reduction in tensile and internal pressure strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

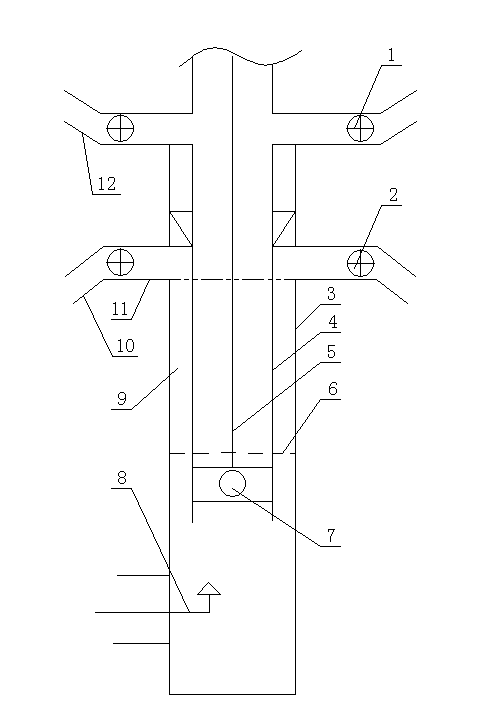

[0022] See attached figure 1 , the mechanical oil recovery is to lift the formation fluid 8 from the downhole to the surface through the oil pump 7 and the sucker rod 5 arranged in the wellbore, and enter the surface transmission pipeline 1 after being controlled by the oil pipe gate 1. During the generation process, the oil pipe 4 The formation fluid level 6 in the annular space between the tubing and casing 3, that is, the annular space 9 between the tubing and the casing fluctuates, and the air is continuously mixed into the formation fluid 8 with high salinity through the casing gate 2, so that It will cause: a. to make the formation fluid corrosive; b. to accelerate the corrosion rate of the formation fluid containing corrosive gases such as hydrogen sulfide and carbon dioxide, and to corrode the wet inner wall of the casing 3 and the outer wall of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com