Microcrystal foamed ceramic composite brick

A foamed ceramic, composite brick technology, applied in ceramic layered products, covering/lining, layered products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

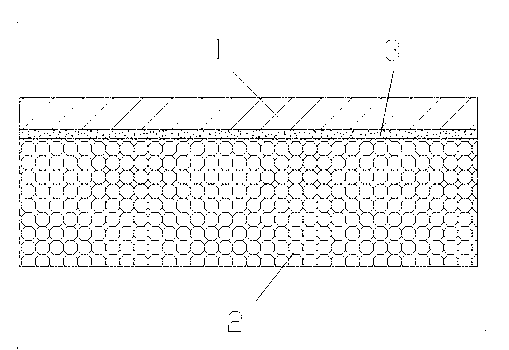

[0018] Such as figure 1 As shown, a microcrystalline foam ceramic composite brick, the microcrystalline foam ceramic composite brick includes microcrystalline foam ceramics 2 and a surface material 1, and there is a layer of adhesive between the surface material 1 and the microcrystalline foam ceramics 2, Paste together with adhesives, the surface material can be natural stone, artificial stone, pottery, stained glass, metal and other materials, the natural stone can be granite, marble, jade and other stone materials, artificial stone can be quartz stone, Granite, microcrystalline stone and other plates.

no. 2 example

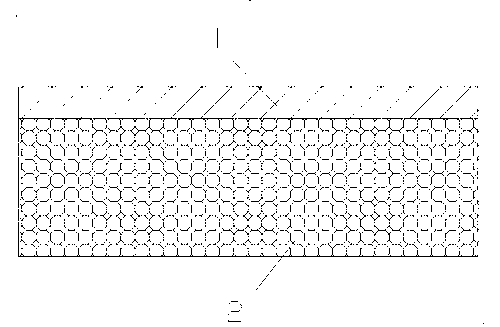

[0020] Such as figure 2 As mentioned above, the surface material can also be ceramics directly glazed on the surface of the microcrystalline foam ceramics and then sintered, and the glaze can be a wet glaze or a dry glaze.

[0021] Microcrystalline foam ceramic composite brick is compounded with a layer of 1~3mm decorative surface material on the basis of microcrystalline foam ceramics to achieve good effects of heat preservation, fire prevention, and high-end decoration. Foamed ceramic composite bricks with natural stone, ceramic sheets and mosaics as surface materials are suitable for exterior wall decoration and decoration, and are also suitable for waterproof, moisture-proof and sound-proof decoration of subway platforms and sunken tunnels; Crystal foam ceramic composite bricks are suitable for building interior walls, screens, office partitions, background walls, etc.; microcrystalline foam ceramic composite bricks with granite, natural stone, quartz stone, and microcrys...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com