Pressurized gas nitriding method on the surface of medium and low carbon alloy structural steel

A technology of low-carbon alloy and pressurized gas, which is applied in metal material coating process, coating, solid-state diffusion coating, etc., can solve the load-carrying and impact-resistant limitations of heavy-duty large-curvature-radius parts, and cannot replace deep carburizing , long time and other issues, to achieve the effect of enhancing the process effect, reducing the decomposition rate, and promoting the adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

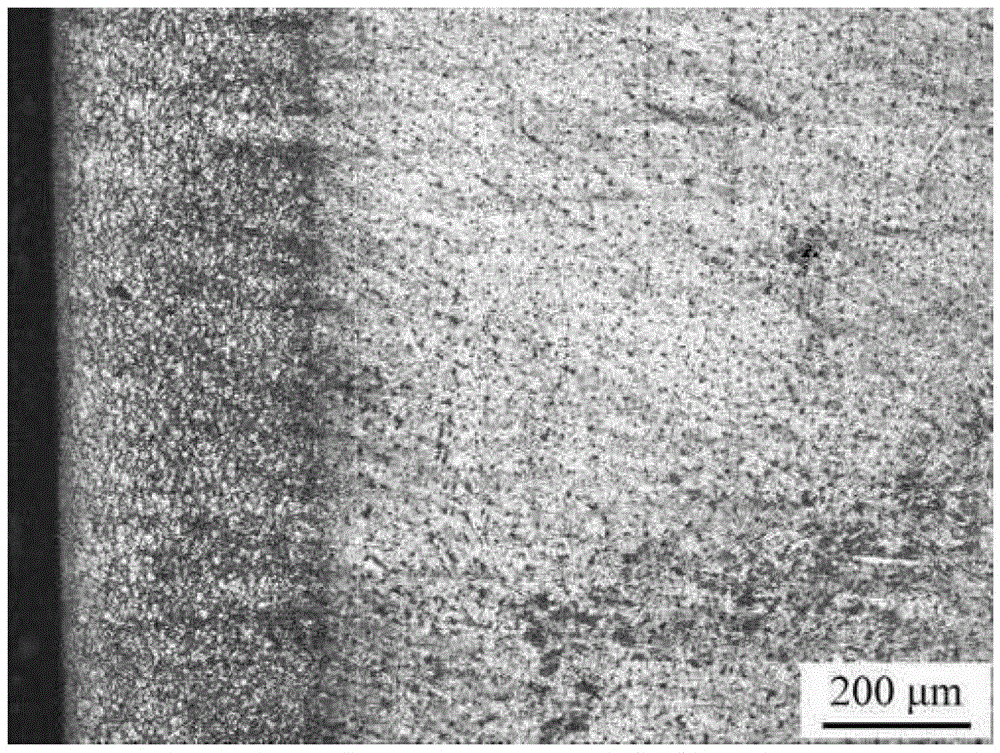

[0014] Process 31CrMoV9 steel into a test piece and hang it in a solid solution nitriding furnace with the patent name "A pressurized high-temperature nitriding device with a double-pressure balance structure" and the patent number 201210530358.6. NH 3 The flow rate is 0.1L / min, the decomposition rate is 30-40%, and the nitriding treatment is carried out for 10 hours, and then NH is continuously fed 3 To the furnace, cooling to 100 ° C to end. Such as figure 1 As shown, the thickness of the infiltrated layer obtained by the test block is about 0.441mm.

Embodiment 2

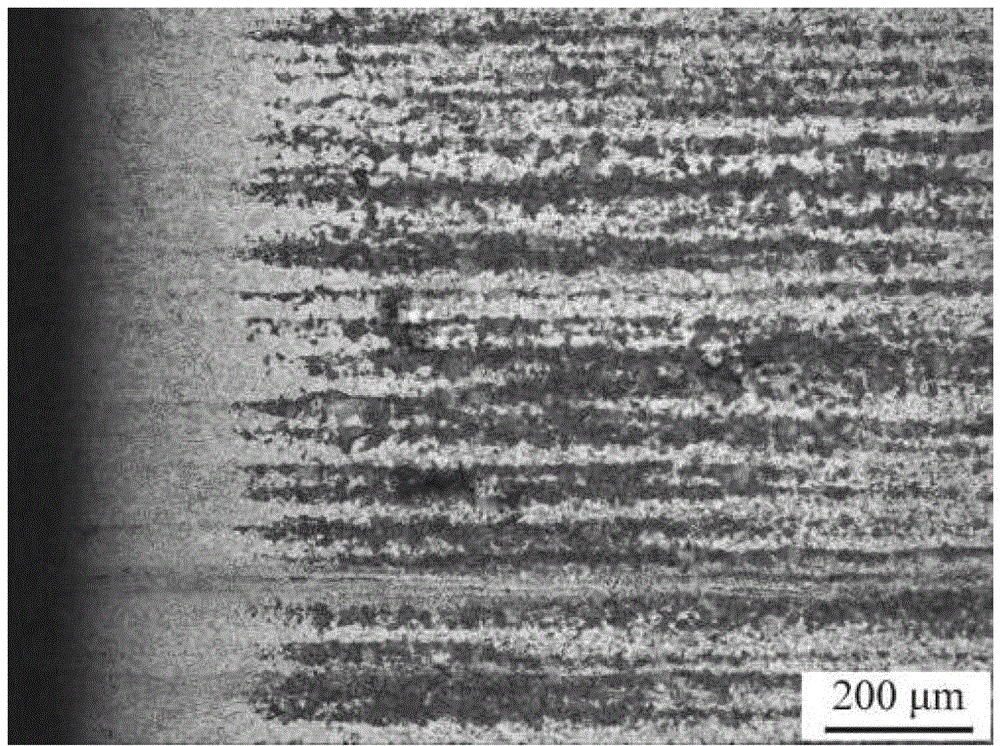

[0016] Process 42CrMo steel into a test block and hang it in a solid solution nitriding furnace with the patent name "A pressurized high-temperature nitriding device with a double-pressure balance structure" and the patent number 201210530358.6. NH 3 The flow rate is 0.3L / min, the decomposition rate is 50-60%, nitriding treatment is carried out for 5 hours, and then NH is continuously fed 3 To the furnace, cooling to 100 ° C to end. Such as figure 2 As shown, the thickness of the infiltrated layer obtained by the specimen is 0.24mm.

Embodiment 3

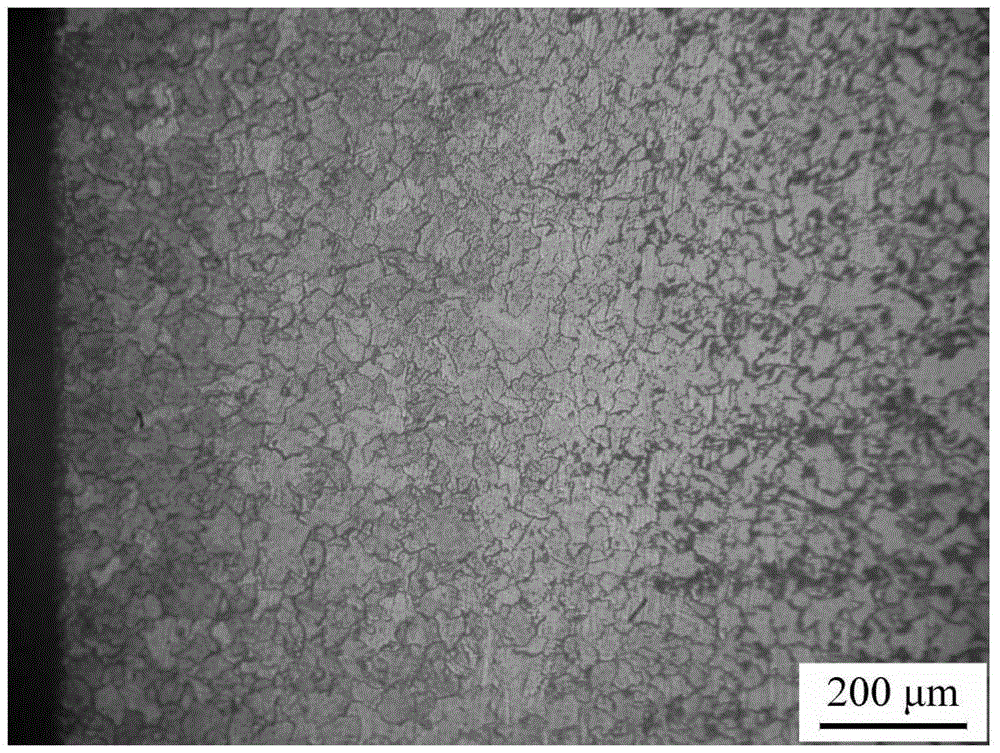

[0018] The 20CrMnTi steel is processed into a test block and hung in the solid solution nitriding furnace with the patent name "A pressurized high-temperature nitriding device with a double-pressure balance structure" and the patent number is 201210530358.6. NH 3 The flow rate is 0.5L / min, the decomposition rate is 60% to 80%, the nitriding treatment is 20h, and then the NH is continuously fed 3 To the furnace, cooling to 100 ° C to end. Such as image 3 As shown, the thickness of the infiltrated layer obtained by the test block is about 0.692mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com