Lubricating defoamer for drilling fluid and preparation method thereof

A defoamer and drilling fluid technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of poor mud lubrication performance, well kick, and decreased drilling fluid density, and achieve good wettability and Permeability, simple on-site operation procedures, and the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

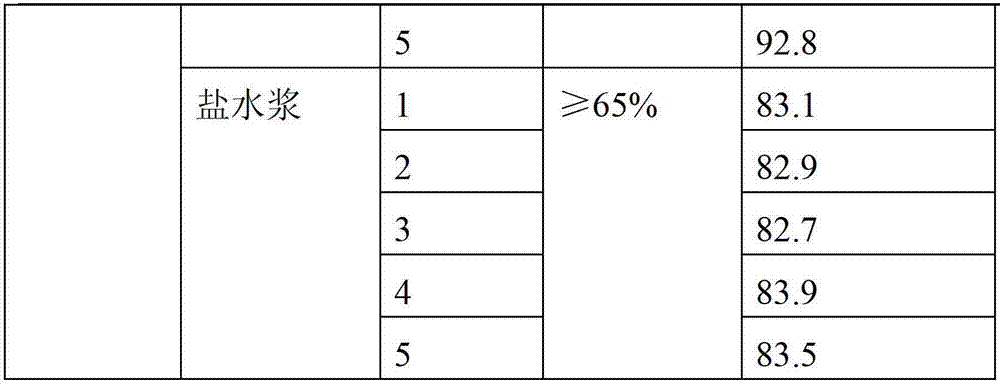

Embodiment 1

[0024] A lubricating defoamer for drilling fluid, which is made of the following components in weight percentage: 34% fatty acid, 18% organic amine; 33% base oil; 3% penetrating agent; 12% defoamer.

[0025] Prepare 5000Kg of drilling fluid lubricating defoamer, the specific raw materials and dosage are: corn oil 1700Kg, divinyl glycol amine 900Kg, aviation kerosene 1650Kg, fatty alcohol polyoxyethylene ether 150Kg, simethicone 600Kg.

[0026] The preparation method of above-mentioned drilling lubricating defoamer, it may further comprise the steps:

[0027] (1) Add corn oil into the reaction kettle and raise the temperature to 70°C while stirring;

[0028] (2) Add diethylene glycol amine into the reactor, keep stirring, continue to heat up to 140°C, and seal the reaction for 8 hours;

[0029] (3) Then add aviation kerosene, fatty alcohol polyoxyethylene ether and simethicone to the reaction kettle, keep stirring, and keep the temperature at 80°C for 4 hours to obtain a finis...

Embodiment 2

[0031] A lubricating defoamer for drilling fluid, which is made of the following components in weight percentage: 32% fatty acid, 16% organic amine; 33% base oil; 5% penetrating agent; 14% defoamer.

[0032] Prepare 5000Kg of lubricating and defoaming agent for drilling fluid. The specific raw materials and dosage are: 1600Kg of mixed oil of rapeseed oil and peanut oil mixed at a weight ratio of 1:1, 800Kg of diethylene glycol amine, 1650Kg of aviation kerosene, fatty alcohol Polyoxyethylene ether 250Kg, simethicone 700Kg.

[0033] The preparation method of above-mentioned drilling lubricating defoamer, it may further comprise the steps:

[0034] (1) Add corn oil into the reaction kettle and raise the temperature to 62°C while stirring;

[0035] (2) Add diethylene glycol amine into the reaction kettle, keep stirring, continue to heat up to 135°C, and seal the reaction for 10h;

[0036] (3) Then add aviation kerosene, fatty alcohol polyoxyethylene ether and simethicone into t...

Embodiment 3

[0038] A lubricating defoamer for drilling fluid, which is made of the following components in weight percentage: 32% fatty acid, 16% organic amine; 38% base oil; 3% penetrating agent; 11% defoamer.

[0039] Prepare 5000Kg of drilling fluid lubricating defoamer, the specific raw materials and dosage are: rapeseed oil, peanut oil, corn oil, soybean oil, olive oil mixed in a weight ratio of 1:1:2:3:1:5:1 1600Kg of mixed oil of sesame oil and sunflower oil, 800Kg of diethylene glycol amine, 1900Kg of aviation kerosene, 150Kg of fatty alcohol polyoxyethylene ether, and 550Kg of dimethicone.

[0040] The preparation method of above-mentioned drilling lubricating defoamer, it may further comprise the steps:

[0041] (1) Add corn oil into the reaction kettle and raise the temperature to 78°C while stirring;

[0042] (2) Add diethylene glycol amine to the reactor, keep stirring, continue to heat up to 148°C, and seal the reaction for 6.5 hours;

[0043] (3) Then add aviation kerosen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com