A kind of modified polycarbonate with good low temperature toughness and preparation method thereof

A polycarbonate and modified technology, applied in the field of modified polycarbonate and its preparation, can solve the problems of not fully meeting the comprehensive performance requirements, notch sensitivity, stress concentration cracking, low temperature impact toughness, etc. Improvement of notch sensitivity and stress cracking, the effect of improving stress cracking and notch sensitivity and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

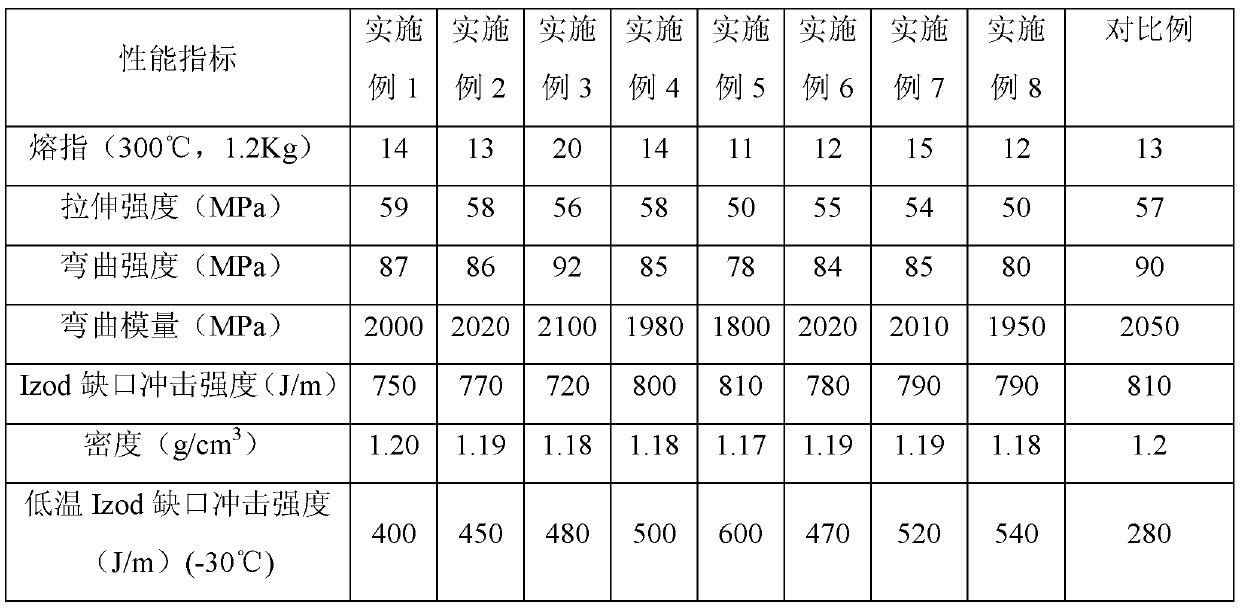

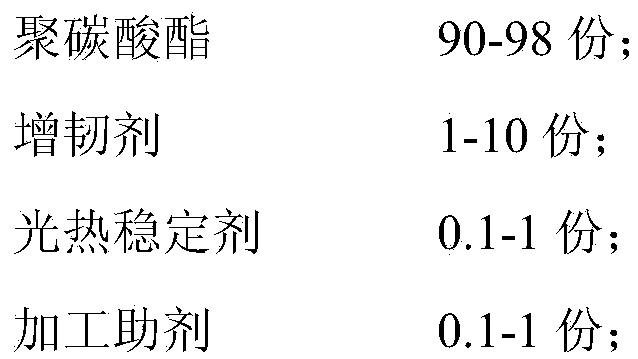

Embodiment 1

[0039] (1) Mix 98 parts of PCIR2200, 1 part of MBSE2620, 0.3 part of light and heat stabilizer (antioxidant 1076:antioxidant 168=1:2 (mass ratio)) and 0.1 part of EBS by high-speed stirring;

[0040] (2) Send the above mixture into the extruder, under the conveying and shearing action of the screw, fully melt and compound, then extrude through the machine head, draw, cool, pelletize, and finally pack to obtain the finished product. The screw temperature of each section of the twin-screw extruder is controlled between 260-280°C, and the screw speed is 400 rpm.

Embodiment 2

[0042] (1) Mix 95 parts of PCIR2200, 3 parts of MBSE2620, 0.6 part of light and heat stabilizer (antioxidant 1076:antioxidant 168=1:2 (mass ratio)), 0.2 part of EBS and 0.3 part of solid paraffin by high-speed stirring Uniform;

[0043] (2) Send the above mixture into the extruder, under the conveying and shearing action of the screw, fully melt and compound, then extrude through the machine head, draw, cool, pelletize, and finally pack to obtain the finished product. The screw temperature of each section of the twin-screw extruder is controlled between 260-280°C, and the screw speed is 400 rpm.

Embodiment 3

[0045] (1) Mix 90 parts of PCIR2200, 10 parts of ABS8434, 0.9 part of light and heat stabilizer (antioxidant 1076:antioxidant 168=1:2 (mass ratio)) and 1.0 part of EBS by high-speed stirring;

[0046] (2) Send the above mixture into the extruder, under the conveying and shearing action of the screw, fully melt and compound, then extrude through the machine head, draw, cool, pelletize, and finally pack to obtain the finished product. The screw temperature of each section of the twin-screw extruder is controlled between 260-280°C, and the screw speed is 400 rpm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com