Tire tread material with high wet and skid resistance and preparation method of material

A wet-slip and tread technology, applied in the field of rubber, can solve the problems of reducing tire safety, poor binding force, affecting tire handling stability, etc., and achieve the effect of reducing rolling resistance and improving wet skid resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

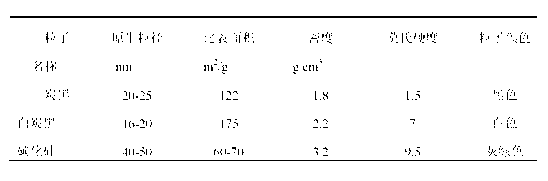

Image

Examples

Embodiment 1

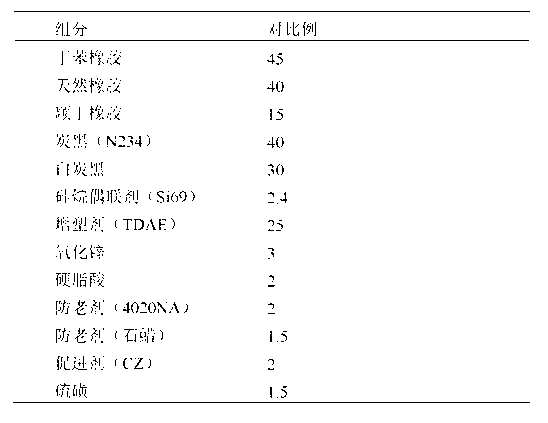

[0027] Embodiment 1: Anti-wet skid tire tread material, the formula of proportion in parts by weight, see Table 3:

[0028] Table 3. Formulation of Example 1

[0029]

[0030] The specific mixing process of composite materials:

[0031] A. Put all styrene-butadiene rubber, natural rubber and butadiene rubber, 10 phr carbon black, 30 phr silica, all silicon carbide and silane coupling agent into the mixing chamber of the internal mixer for mixing , the mixing temperature is controlled at 155° C., and the mixing time is 240 seconds; the glue is removed to obtain a section of mixed rubber, and a section of mixed rubber is cooled to room temperature in air.

[0032] B. Put the mixed rubber obtained in step A, the remaining 30 phr carbon black, all zinc oxide, stearic acid, anti-aging agent, and plasticizer into the mixing chamber of the internal mixer for mixing, and the mixing temperature is controlled at 155 °C, the mixing time is 240 seconds; the glue is discharged to obta...

Embodiment 2

[0034] Embodiment 2: Anti-wet skid tire tread material, the formula of proportioning in parts by weight, see Table 4:

[0035] Table 4. Formulation of Example 2

[0036]

[0037] The specific mixing process of composite materials:

[0038] A. Put all styrene-butadiene rubber, natural rubber and butadiene rubber, 10 phr carbon black, 30 phr silica, all silicon carbide and silane coupling agent into the mixing chamber of the internal mixer for mixing, mixing The mixing temperature is controlled at 155° C., and the mixing time is 240 seconds; the glue is discharged to obtain a section of mixed rubber, and a section of mixed rubber is cooled to room temperature in air.

[0039] B. Put the mixed rubber obtained in step A, the remaining 30 phr carbon black, all zinc oxide, stearic acid, anti-aging agent, and plasticizer into the mixing chamber of the internal mixer for mixing, and the mixing temperature is controlled at 155 °C, the mixing time is 240 seconds; the glue is discha...

Embodiment 3

[0041] Embodiment 3: anti-wet skid tire tread material, the formula of proportion in parts by weight, see Table 5:

[0042] Table 5. Formulation of Example 3

[0043]

[0044] The specific mixing process of composite materials:

[0045] A. Put all the styrene-butadiene rubber and butadiene rubber, 40 phr of white carbon black, all the silicon carbide and silane coupling agent into the mixing chamber of the internal mixer for mixing, the mixing temperature is controlled at 155°C, and the mixing The time is 240 seconds; the glue is discharged to obtain a section of mixed rubber, and a section of mixed rubber is cooled to room temperature in air.

[0046] B. Put the mixed rubber obtained in step A, the remaining 40 phr silica, all zinc oxide, stearic acid, anti-aging agent, and plasticizer into the mixing chamber of the internal mixer for mixing, and the mixing temperature is controlled at 155°C, and the mixing time is 240 seconds; the glue is discharged to obtain the second...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com