Method for ionothermal synthesis of aluminum phosphate AlPO4-n zeolite membranes

A technology of ionothermal synthesis and alpo4-n, which is applied in the synthesis and application of molecular sieve membranes, can solve the problems of rare molecular sieve membranes and achieve excellent anti-corrosion performance and high repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

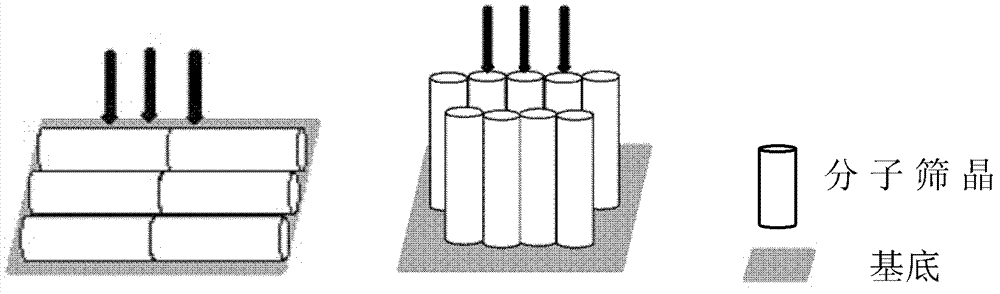

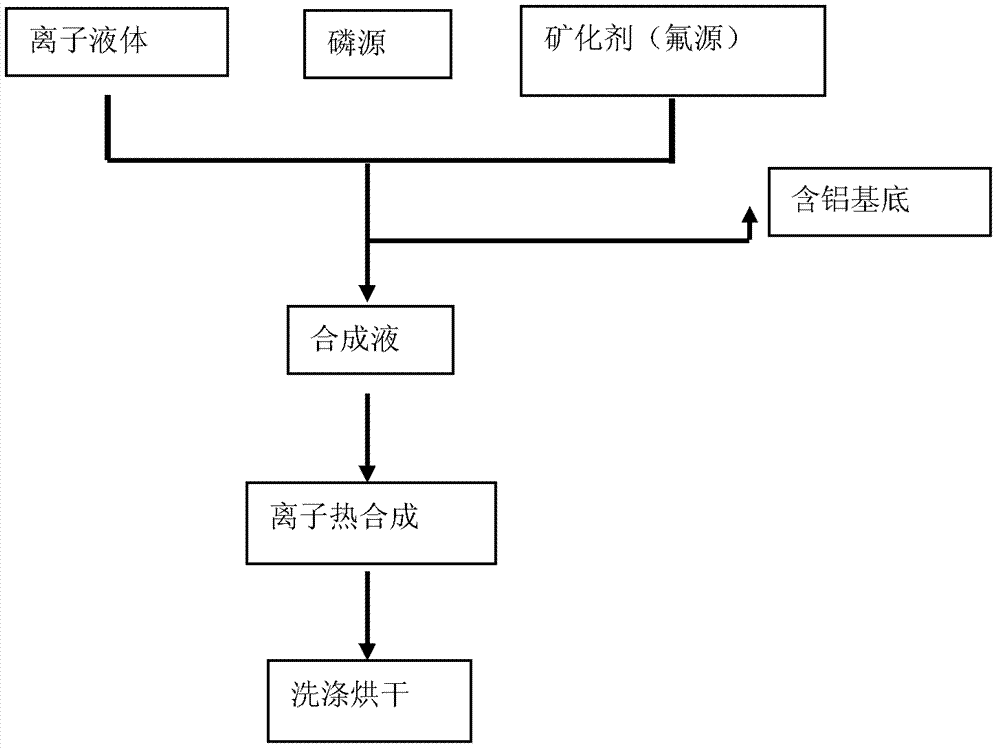

[0028] Example 1 AlPO 4 Preparation of -11 molecular sieve membrane

[0029]The substrate used for synthesizing the molecular sieve membrane is a pure aluminum sheet with a purity of 99.99%, a length of 37mm, and a width of 18mm. The substrate is ultrasonically washed in acetone before use, and then dried with high-pressure air for use.

[0030] The synthesis solution for synthesizing molecular sieve membranes is configured as follows:

[0031] 1.72 g of phosphoric acid (85%) and 0.2 g of HF (40%) were added to 30.57 g of 1-ethyl-3-methyl-imidazolium bromide ionic liquid, heated and stirred at 90° C. for 1 hour.

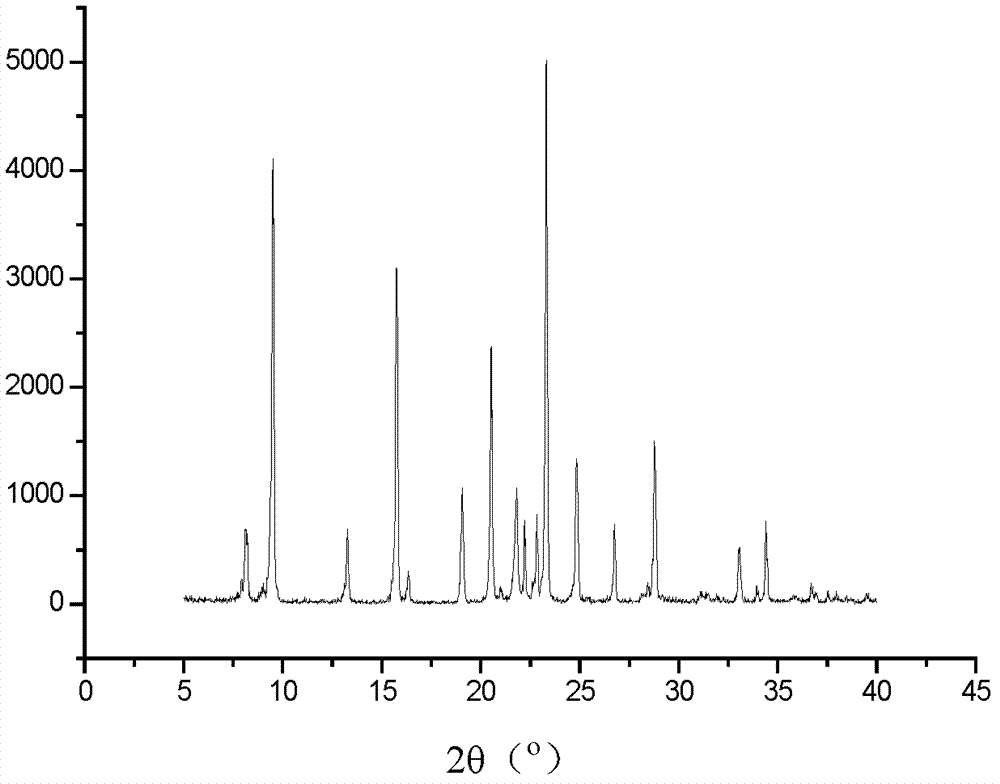

[0032] Place the pure aluminum sheet vertically in the polytetrafluoroethylene synthesis kettle, pour the synthesis liquid into the synthesis kettle, wrap the heating jacket on the outside of the synthesis kettle, heat it up to 190°C, and keep heating at this temperature for 4 hours; The synthesized aluminum flakes were washed with deionized water, dried with high...

Embodiment 2

[0033] Example 2 AlPO 4 Preparation of -11 molecular sieve membrane

[0034] By the same operation of Example 1, just change the heating temperature of the synthetic liquid: 1.72 gram of phosphoric acid (85%) and 0.2 gram of HF (40%) are added to 30.57 gram of 1-ethyl-3-methyl-imidazolium bromide ionic liquid , heated and stirred at 90°C for 1 hour. Place the pure aluminum sheet vertically in the polytetrafluoroethylene synthesis kettle, pour the synthesis liquid into the synthesis kettle, wrap the heating jacket on the outside of the synthesis kettle, heat it up to 150°C, and keep heating at this temperature for 4 hours; The synthesized aluminum flakes were washed with deionized water, dried with high-pressure air, and then oven-dried at 60°C overnight. The obtained molecular sieve was confirmed to have an AEL structure by X-ray diffraction, but the compactness of the film was poor.

Embodiment 3

[0035] Example 3 AlPO 4 Preparation of -11 molecular sieve membrane

[0036] By the same operation of Example 1, just change the heating temperature of the synthetic liquid: 1.72 gram of phosphoric acid (85%) and 0.2 gram of HF (40%) are added to 30.57 gram of 1-ethyl-3-methyl-imidazolium bromide ionic liquid , heated and stirred at 90°C for 1 hour. Place the pure aluminum sheet vertically in the polytetrafluoroethylene synthesis kettle, pour the synthesis liquid into the synthesis kettle, wrap the heating jacket on the outside of the synthesis kettle, heat it up to 220°C, and keep heating at this temperature for 4 hours; The synthesized aluminum flakes were washed with deionized water, dried with high-pressure air, and then oven-dried at 60°C overnight. The obtained molecular sieve was confirmed to have an AEL structure by X-ray diffraction, but the compactness of the film was poor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com