Preparation method of hydroxyapatite containing Sn(II)

A hydroxyapatite and group technology, which is applied in the field of preparation of Sn-containing hydroxyapatite, can solve the problems of high temperature, do not contain biological active materials such as hydroxyapatite, increase production cost, etc., and achieve uniform particle size and phase. high purity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] 1) First, dissolve calcium chloride and stannous chloride in hydrochloric acid solution to obtain solution A, and Sn in solution A 2+ and Ca 2+ The molar ratio Sn / (Ca+Sn)=0.01;

[0032] 2) Second, will contain H 3 PO 4 The phosphoric acid solution of the group is added to solution A according to the molar ratio of (Ca+Sn):P=10:6, and then NaOH solution is added to adjust the solution to be alkaline to obtain a mixed solution;

[0033] 3) Transfer the mixed solution to an oven for reaction, control the reaction temperature at 60°C, and react for 48 hours;

[0034] 4) Filter the reacted solution under reduced pressure, rinse with alkaline solution, and finally rinse the filter cake with distilled water until neutral;

[0035] 5) Move the filter cake to an oven to dry and then prepare the desired powder.

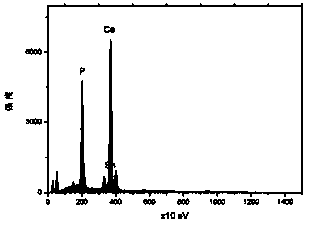

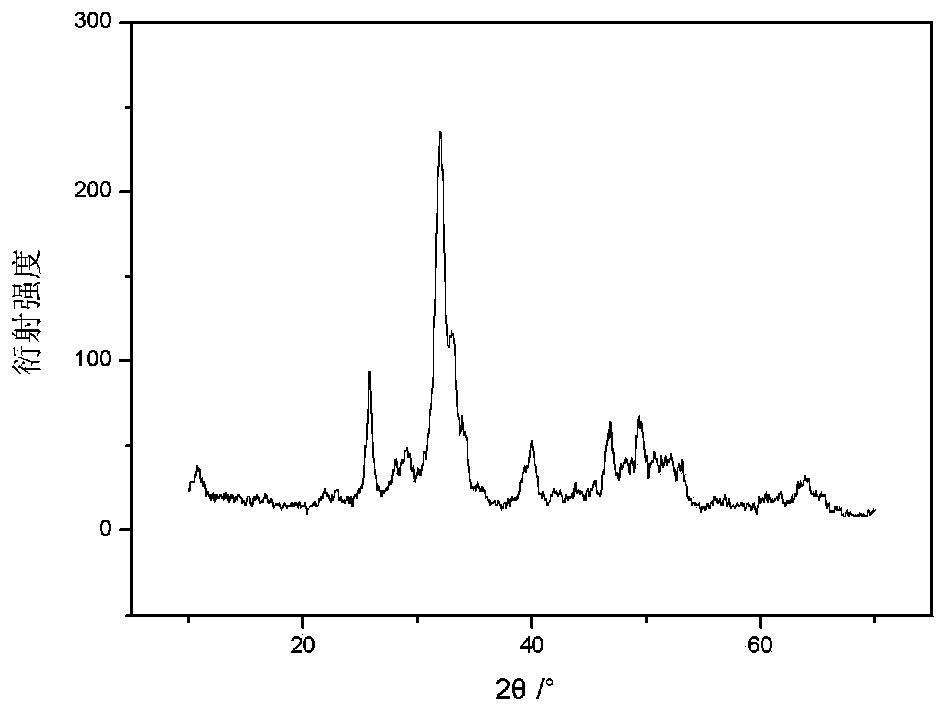

[0036] The XRD diffraction pattern of gained powder is as figure 1 As shown, the phase shown in the figure is hydroxyapatite phase, the diffraction peak has a cert...

Embodiment 2

[0038] 1) First, dissolve calcium nitrate and stannous nitrate in nitric acid solution to obtain solution A. In solution A, Sn 2+ and Ca 2+ The molar ratio Sn / (Ca+Sn)=0.1;

[0039] 2) Second, will contain H 2 PO 4 - The potassium dihydrogen phosphate of the group is added to the solution A according to the molar ratio of (Ca+Sn):P=10:6, and then the KOH solution is added to adjust the solution to be alkaline to obtain a mixed solution;

[0040] 3) Transfer the mixed solution to an oven for reaction, control the reaction temperature at 80°C, and react for 30 hours;

[0041] 4) Filter the reacted solution under reduced pressure, rinse with alkaline solution, and finally rinse the filter cake with distilled water until neutral;

[0042] 5) Move the filter cake to an oven to dry and then prepare the desired powder.

Embodiment 3

[0044] 1) First, dissolve calcium chloride and stannous sulfate in hydrochloric acid solution to obtain solution A, and Sn in solution A 2+ and Ca 2+ The molar ratio Sn / (Ca+Sn)=0.05;

[0045] 2) Second, will contain H 2 PO 4 - The sodium dihydrogen phosphate solution of the group is added to solution A according to the molar ratio of (Ca+Sn):P=10:6, and then NH 3 ·H 2 The O solution adjusts the solution to be alkaline to obtain a mixed solution;

[0046]3) Transfer the mixed solution to an oven for reaction, control the reaction temperature at 70°C, and react for 36 hours;

[0047] 4) Filter the reacted solution under reduced pressure, rinse with alkaline solution, and finally rinse the filter cake with distilled water until neutral;

[0048] 5) Move the filter cake to an oven to dry and then prepare the desired powder.

[0049] Its SEM picture is as image 3 As shown, the corresponding energy spectrum analysis shows that the molar ratio of (Ca+Sn) / P is 1.6678, which ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com